Method for regulating terminal voltage of cathode during overdischarge and cathode active material for lithium secondary battery

A technology of cathode active material and lithium secondary battery, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of battery capacity decline and battery unusability, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

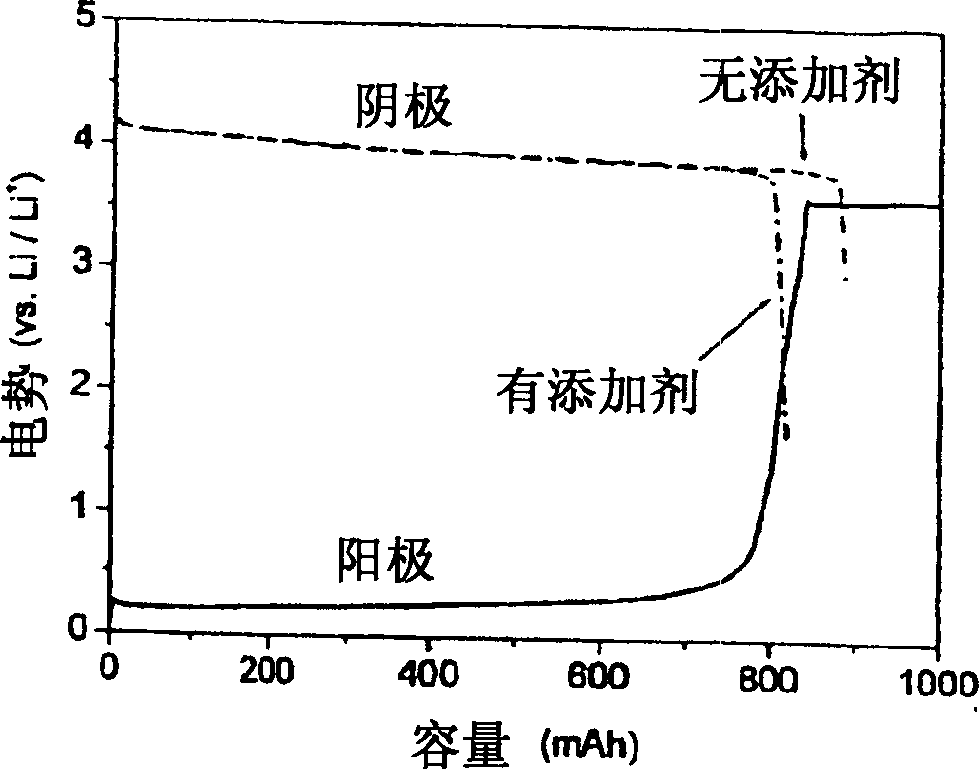

[0082] A pouch-shaped binary battery was prepared by a conventional method. LiCoO 2 As the cathode active material, and adding Li 2 NiO 2 As an additive, its addition amount was 2 parts by weight based on 100 parts by weight of the cathode active material. More specifically, 78.4 wt.% LiCoO was added to NMP as a solvent 2 , 1.6wt.% Li 2 NiO 2 , 10wt.% of KS-6 (conducting agent) and 10wt.% of PVDF (binder) to form a cathode mixture slurry, and then coating the slurry on an Al current collector to obtain a cathode. In addition, artificial graphite and copper were used as anode active material and anode current collector respectively, and 1M LiPF 6 The EC / PC / DEC-based solution was used as the electrolyte to obtain the battery by conventional methods.

Embodiment 2

[0084] Repeat the method of embodiment 1 to prepare battery, except the Li as cathode active material additive 2 NiO 2 The amount used is 5 parts by weight based on 100 parts by weight of the cathode active material.

Embodiment 3

[0086] Repeat the method of embodiment 1 to prepare battery, except the Li as cathode active material additive 2 NiO 2 The amount of used is 9 parts by weight based on 100 parts by weight of the cathode active material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com