Substrate carrying apparatus

A substrate handling and substrate technology, which is applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of weak correction force of substrate P warpage and cannot effectively prevent substrate P warpage, etc., and achieve the effect of accurate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preferred embodiment of a substrate transfer apparatus for carrying out the present invention will be described below with reference to FIGS. 1-5.

[0033] In this example, a suitable device for continuously moving a printed circuit board inside a reflow oven for soldering work is shown.

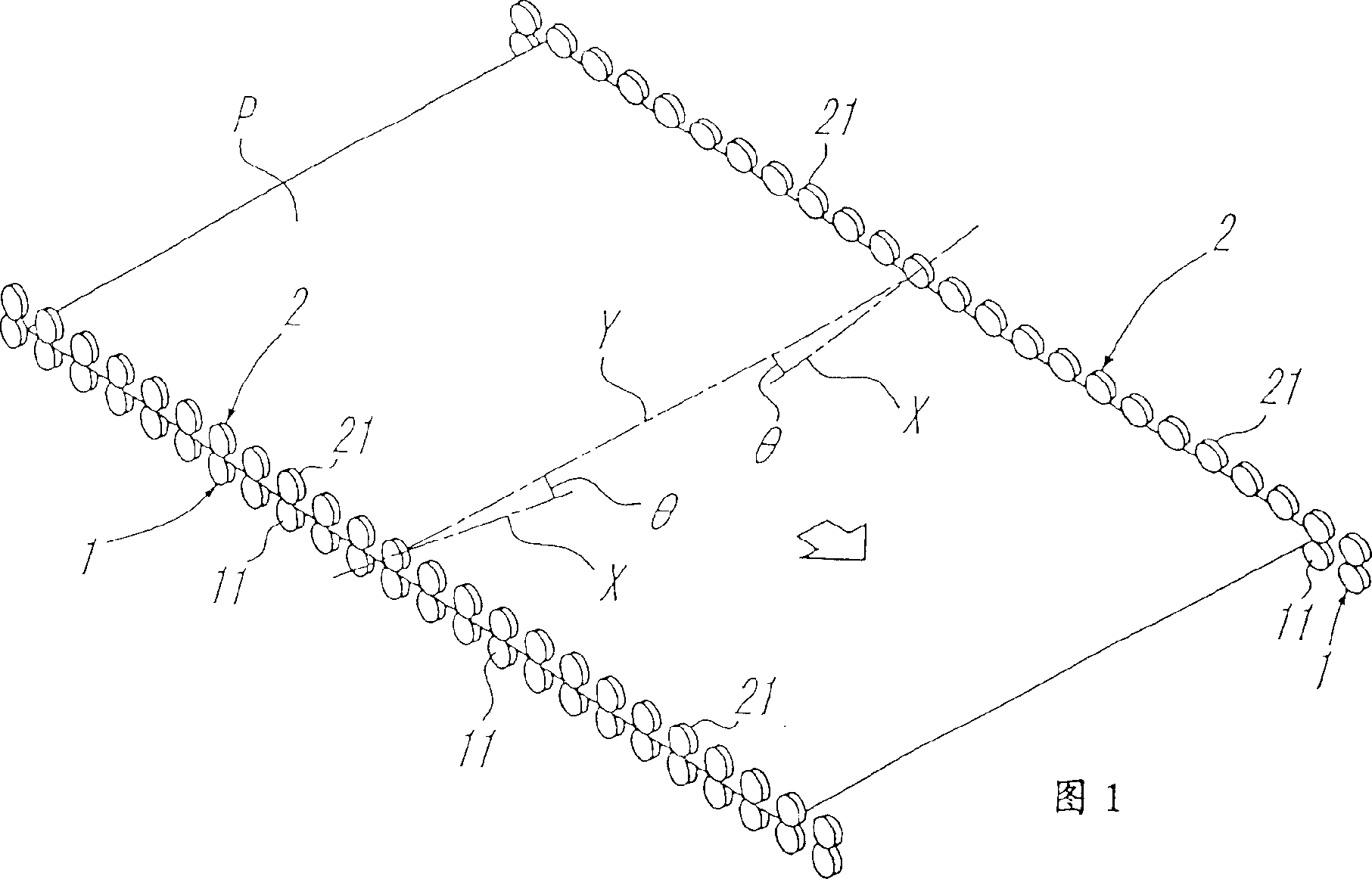

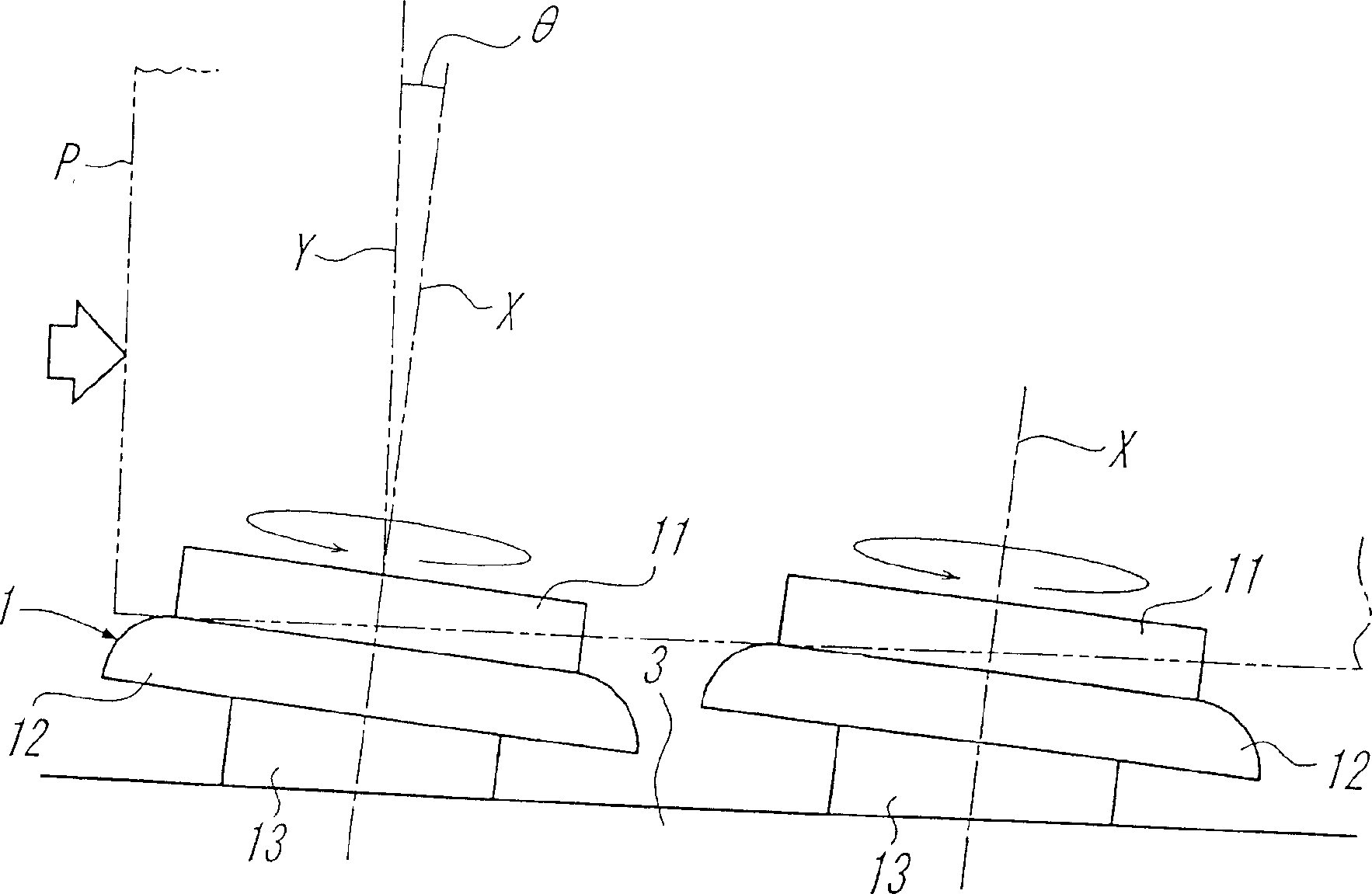

[0034] Like the substrate conveying device in Patent Document 1, this embodiment includes a pair of roller rows 1 and 2 that clamp both side edges of the substrate P from the upper and lower sides, respectively.

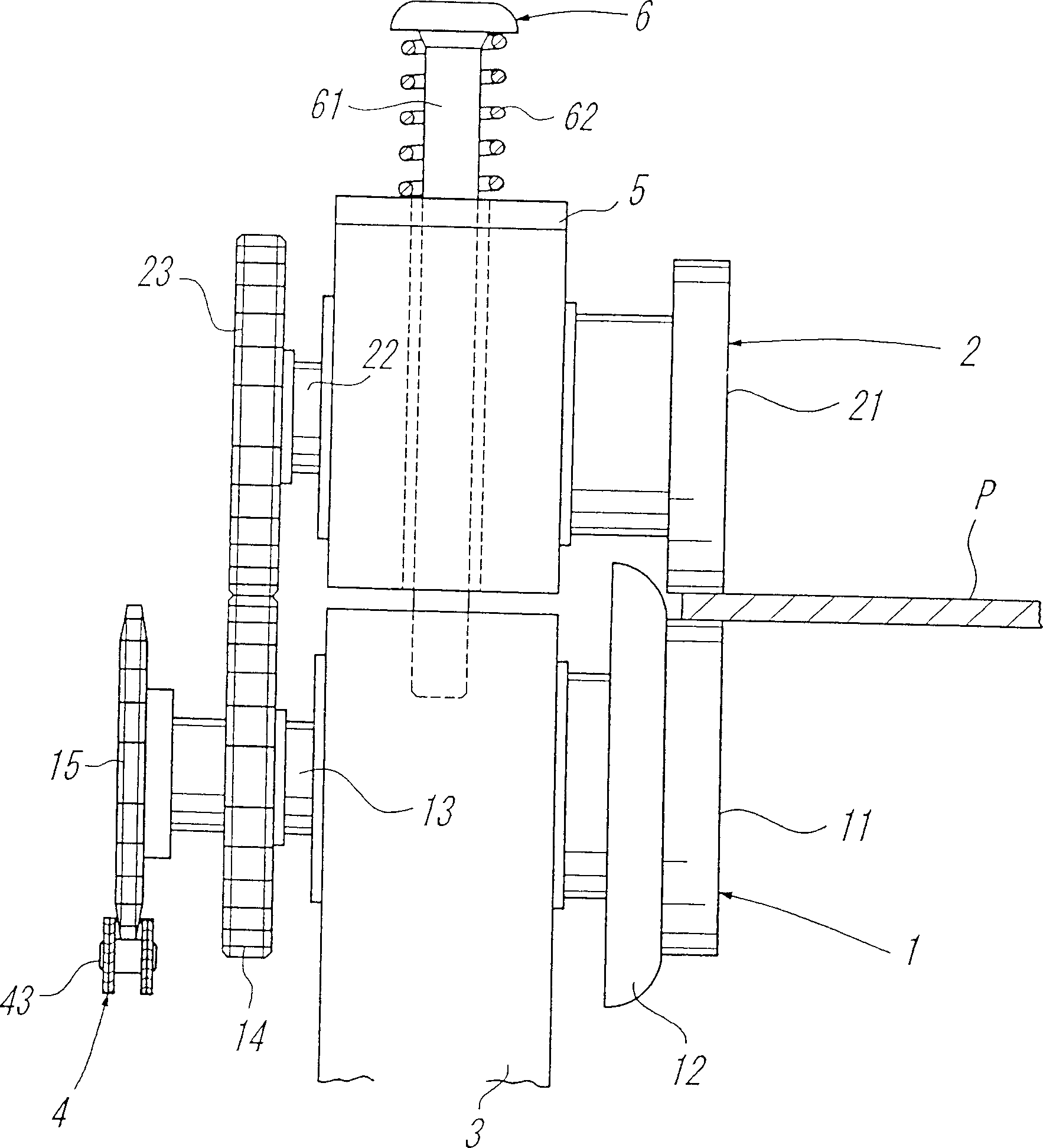

[0035] Such as figure 2 , image 3 As shown, each roller 11 constituting the lower roller row 1 is formed by a flange 12 capable of preventing the substrate P from moving laterally, and is rotatably supported on the fixed frame 3 via a rotating shaft 13 . The synchronous gear 14 and the driving sprocket 15 are coaxially fixed on the rotating shaft 13 . Figure 1, figure 2 As shown, relative to the line Y perpendicular to the substrate P conveying direction, the axis X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com