Method for working shaft-like workpiece by numerical control lathe and its control device

A technology of numerical control lathes and control devices, which is applied to the transformation of ordinary lathes and the field of numerical control devices. It can solve problems such as high requirements for operator skills, delayed delivery, and heavy workload of programmers, so as to reduce training investment and reduce Effect of skill requirements and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

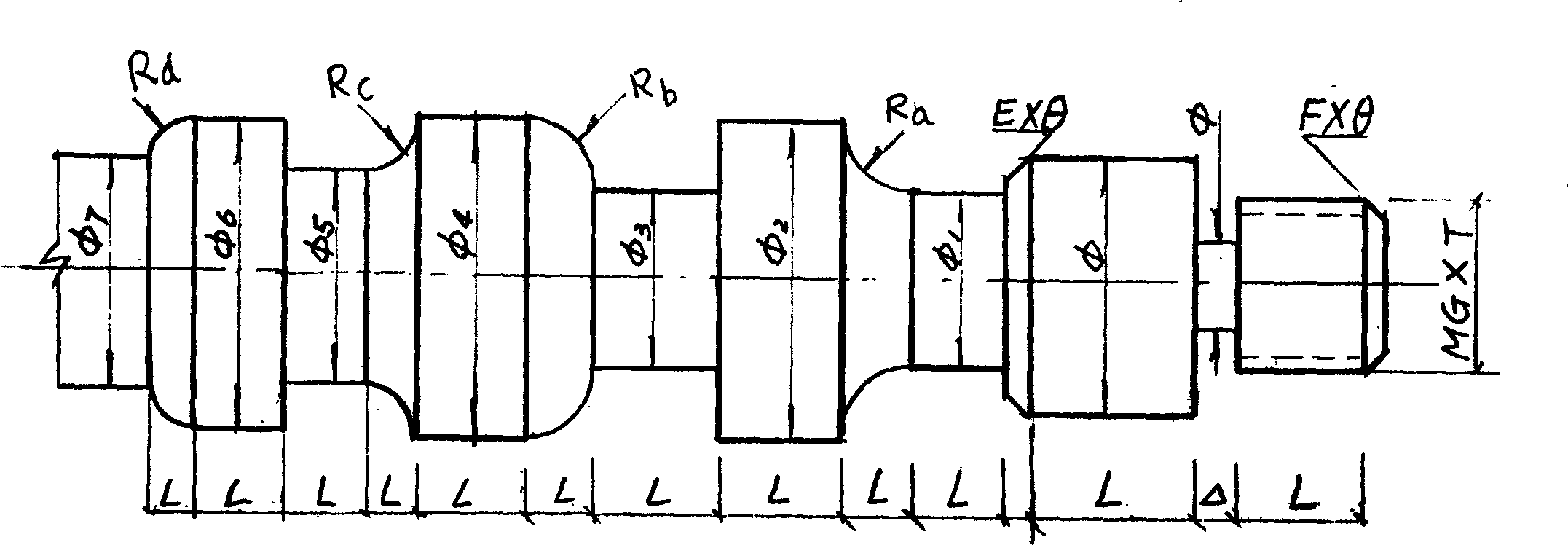

[0028] Compile the processing technology of the virtual "composite parts", write the NC processing program according to the processing technology, and store it in the ROM of the lathe control computer. The program has a program segment corresponding to each feature segment.

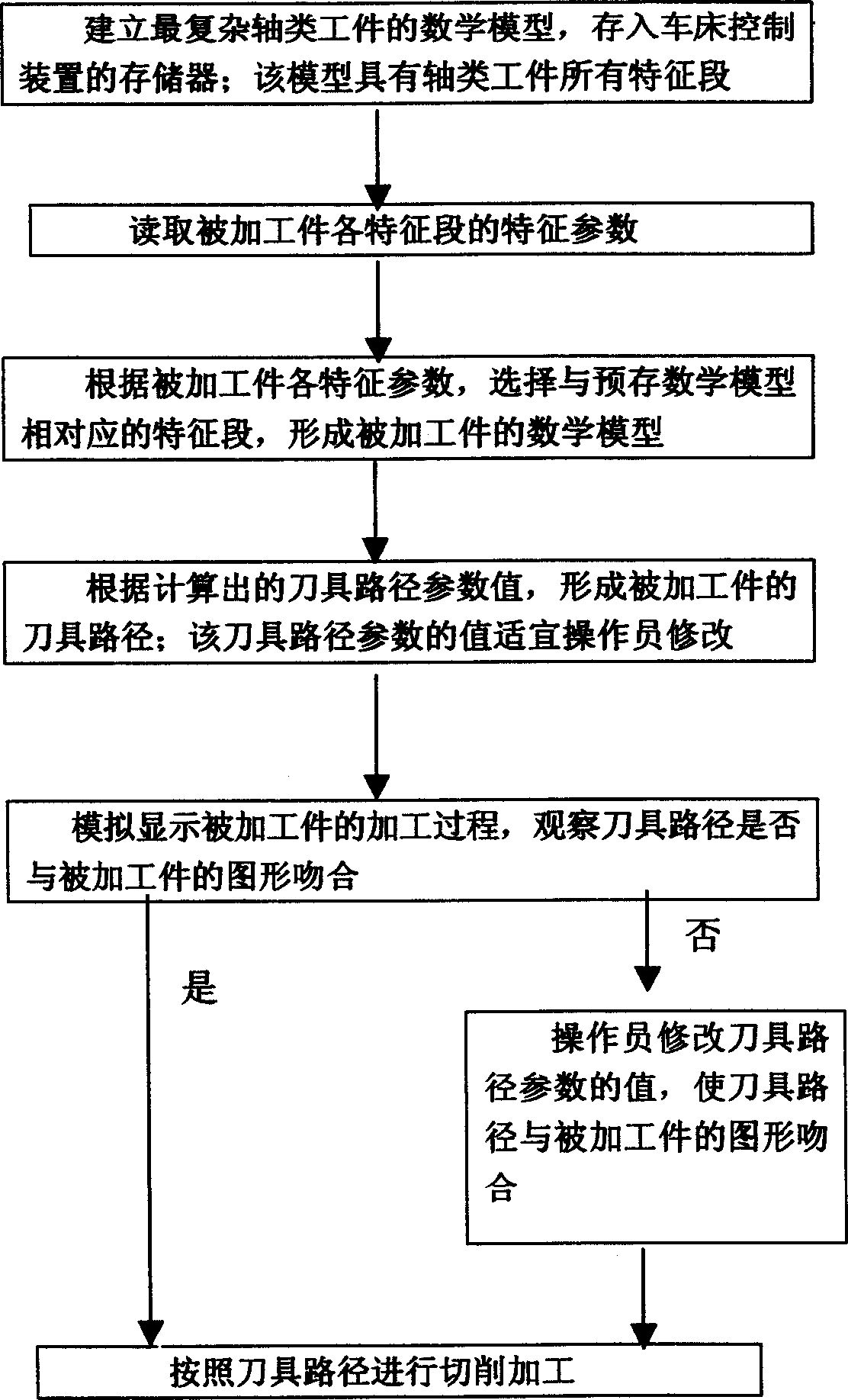

[0029] see figure 1 , the specific process is as follows:

[0030] After the computer is turned on, the operator inputs the characteristic parameters of each segment segment by segment according to the connection sequence of each segment of the workpiece to be processed. After the computer reads it, it selects the corresponding segment in the pre-stored model, and calculates segment by segment based on the value of the input parameters. , Modify each feature segment to form the model of the workpiece.

[0031] For example: the first segment of the workpiece is a threaded segment, then input its parameters outer diameter G, pitch T, length L and their values, after the computer reads it, select the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com