Iron-nickel alloy with low coefficient of thermal expansion for making shade masks

A technology of alloy and shadow mask, which is applied in the field of manufacturing shadow masks of color display cathode ray tubes

Inactive Publication Date: 2006-03-01

伊菲合金公司

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Currently, the mechanical properties of the prior art alloys are not good enough to allow the thickness of the shadow mask to be reduced while allowing the mask to withstand possible deformations during the various shipping and handling steps

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0064] The present invention will now be described in more detail but not limitatively, and illustrated by examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

An iron-nickel alloy has the following chemical composition (by wt %): (a) 35 at most Ni at most 37; (b) 0.001 at most C at most 0.05; (c) Mn at most 0.10; (d) Si at most 0.15; (e) Co at most 0.5; (f) S less than 0.002; (g) P less than 0.006; (h) B at most 0.0005; (i) Al+Mo+Cu+Cr at most 0.15; (j) 0.15 at most 2(V+Ti)+Nb+Zr+Ta+Hf at most 0.2; (k) 0.0025 at most N+O at most 0.015; (l) possibly some calcium and / or magnesium with a total content between 0.0001 and 0.005; (m) a balance of iron and inevitable production impurities. An Independent claim is also included for the fabrication of a strip of the above alloy by hot rolling.

Description

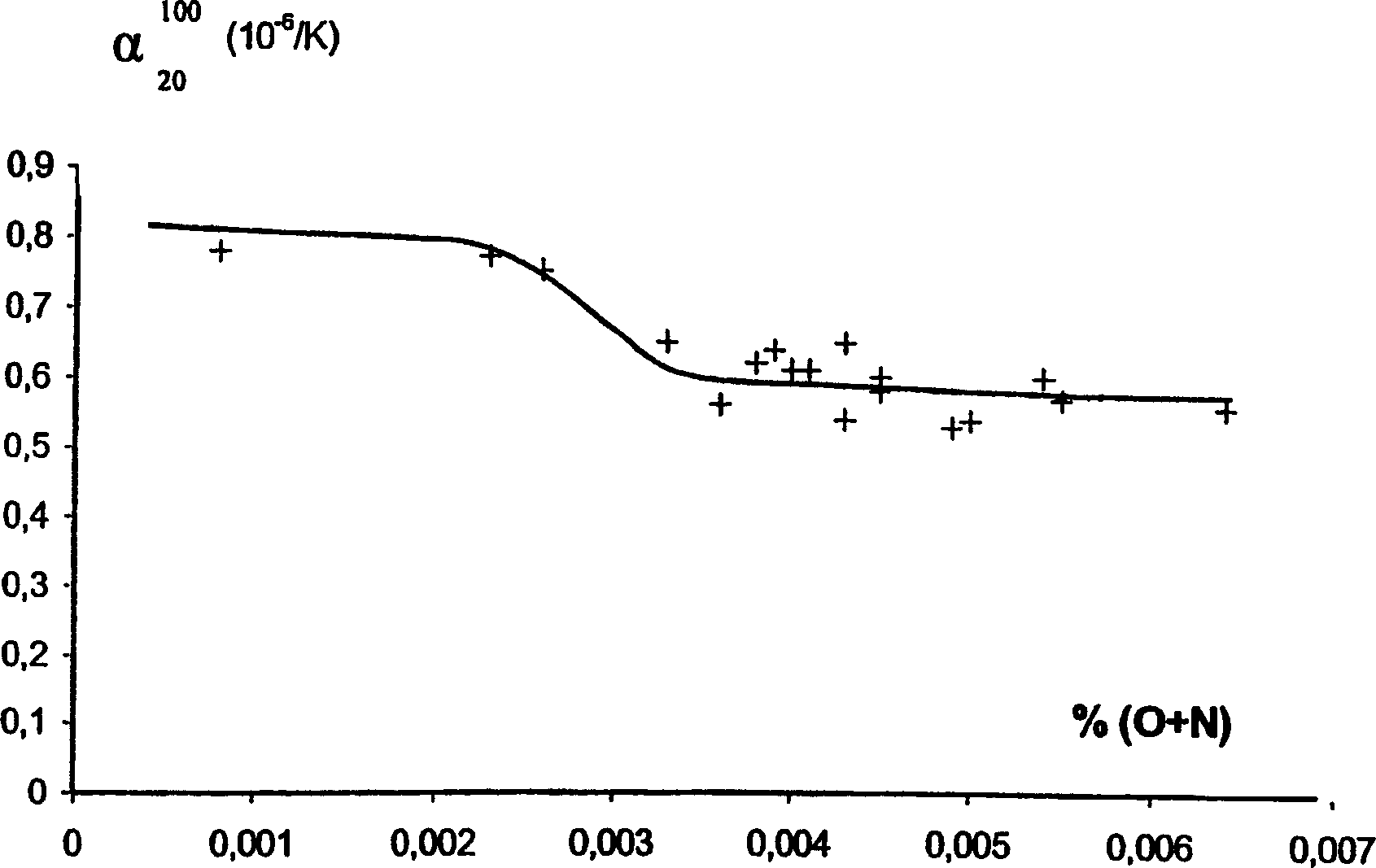

Technical field [0001] The present invention relates to an iron-nickel-based alloy with a very low expansion coefficient. The alloy is particularly useful for manufacturing shadow masks of color developing cathode ray tubes. Background technique [0002] In order to avoid local deformation of shadow masks used in color developing cathode ray tubes due to thermal expansion, it is desirable to use an alloy having the lowest possible thermal expansion coefficient to make them. Therefore, for example, a well-known FeNi alloy called Invar is used, which contains about 36% nickel and about 0.3% manganese. This alloy has about 1×10 -6 / k The coefficient of thermal expansion between 20°C and 100°C. [0003] However, the coefficient of expansion is still too high for some applications such as flat screens, so it is proposed to use FeNi alloys in which a small percentage of nickel is replaced by cobalt. The advantage of this alloy is that it has a 60% reduction of about 0.4×10 -6 / k therma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/08C21D8/02C22C38/00C22C38/10C22C38/12C22C38/14H01J1/48H01J9/14H01J29/07

CPCC22C38/14C21D8/0205H01J9/142C22C38/004H01J9/14C22C38/12C22C38/105C21D8/0226C22C38/08H01J1/48H01J2229/0733H01J29/07C23F1/02

Inventor F·加邦S·维茨克O·达尼洛瓦

Owner 伊菲合金公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com