Ejector capable of raising the cavitation performance of centrifugal pump

A technology for ejectors and centrifugal pumps, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as complex structures, narrow working ranges, and ineffective cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

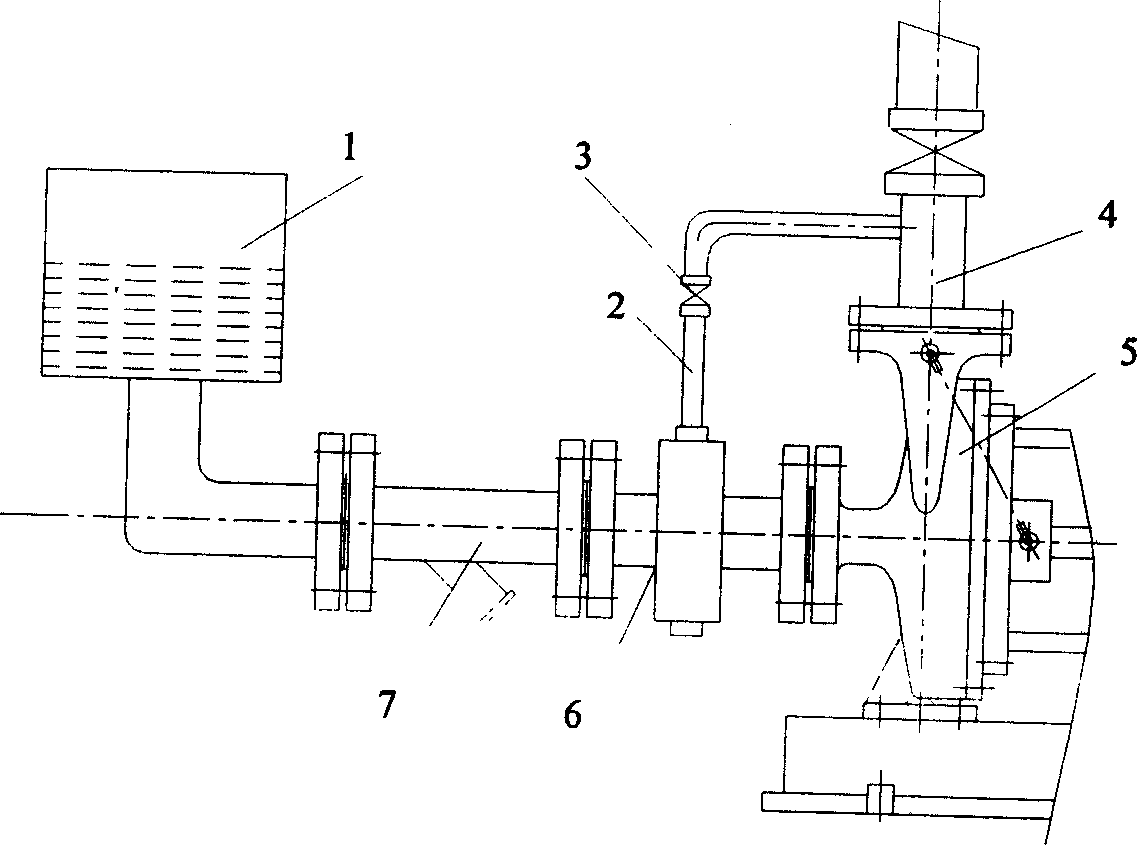

[0014] Such as figure 1 As shown, in the centrifugal pump of the present invention installed, the high-energy liquid at the outlet of the centrifugal pump 5 is led back to the ejector 6 before the pump inlet from the pump outlet discharge pipe 4 through the return pipeline 2 on the ejector circuit, and The front end of the injector 6 is connected to the water tank 1 through the inlet pipe 7, and the rear end is connected to the inlet of the pump. The size of the return flow is adjusted by valve 3. The ejector and the pump body of the centrifugal pump are connected by bolts.

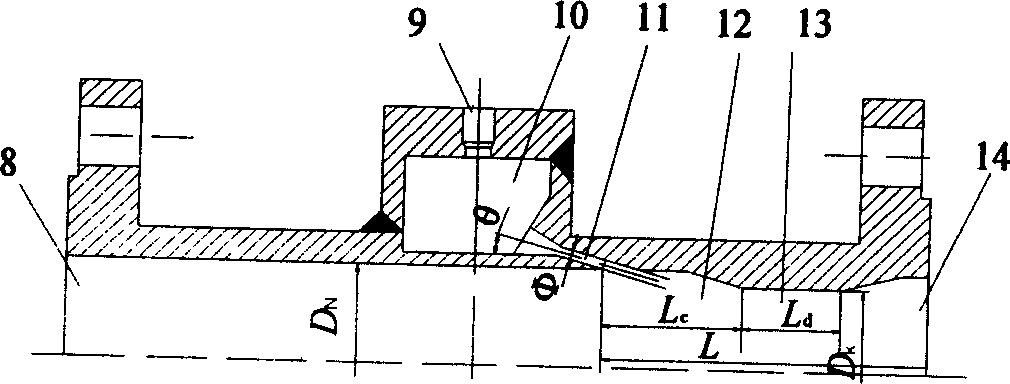

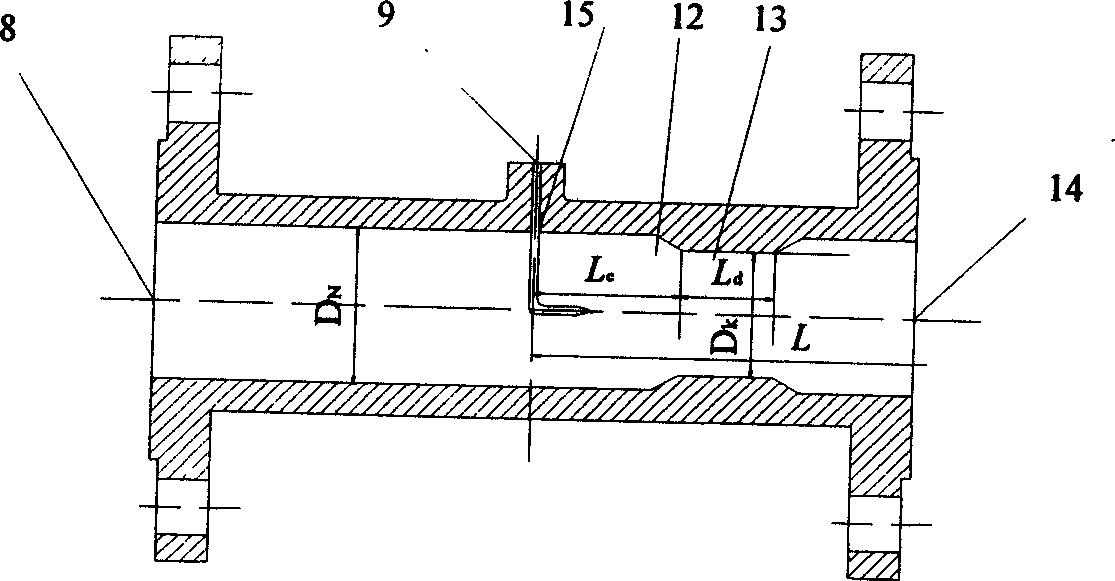

[0015] The present invention is installed before the inlet of the centrifugal pump 5, and part of the high-energy liquid at the outlet of the centrifugal pump is led back to the ejector 6 through the ejector circuit between the outlet discharge pipe 4 of the centrifugal pump 5 and the ejector interface 9 of the ejector 6. The injection interface 9, the fluid introduced back from the injection interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com