Deviation correcting pressure weight method for side rolling in double circle shield tunnel construction

A double-circle shield and tunnel construction technology, which is applied to tunnels, earth square drilling, mining equipment, etc., can solve problems such as blind operations, achieve simple and practical correction methods, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Weight correction under the condition of small deflection angle (0.25 degrees)

[0024] Embodiment Take the construction of the double-circle shield tunnel in the tenth bid section of Shanghai Metro Line 6 as an example. According to the structure and soil conditions of the double-circle shield machine, the load required by the double-circle shield machine when the given deflection angle returns to zero is calculated by applying the finite element method. The relationship between the corresponding deflection angle correction load (kN) is as follows :

[0025] A deflection angle of 0.1° requires a deflection load of 92kN; a deflection angle of 0.2° requires a deflection load of 168kN; a deflection angle of 0.3° requires a deflection load of 230kN; a deflection angle of 0.4° requires a deflection load of 290kN; a deflection angle of 0.5° requires a deflection load of 345kN; A deflection angle of 0.6 degrees requires a correcting load of 395 kN; a deflection an...

Embodiment 2

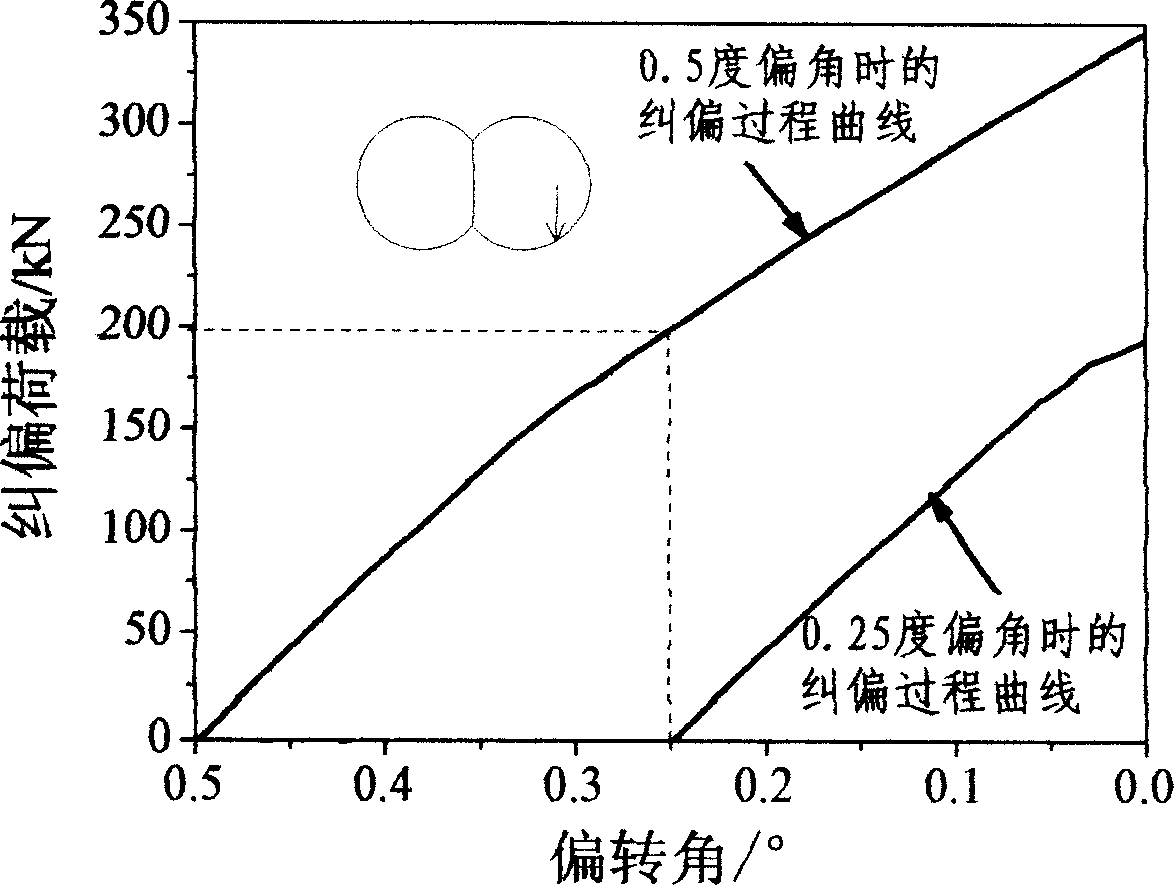

[0027] Embodiment 2: Weight correction under the condition of large deflection angle (0.5 degrees)

[0028] In the construction of the tenth section of Shanghai Metro Line 6, when the deflection angle is relatively large, such as 0.5 degrees. According to the formation conditions in Shanghai, the ballast correction load calculated by the finite element method is 345kN. At this time, 345 / 2=173 pieces of lead are needed. But in fact, the free space of the shield machine is limited, and only about 100 lead blocks can be placed. Only the method of partial weight correction can be used. At this time, the weight is 200kN. figure 2 It is the weight correction process curve at 0.5° deflection angle calculated by applying the method of finite element numerical analysis. It can be seen from this that the 200kN ballast can make the double-circle shield rotate 0.25 degrees. The other deflection angle of 0.25 degrees is solved according to the method of controlling the rotation angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com