Preflex prestressed concrete channel beam and its making method

A production method and concrete technology, which is applied in the field of bridge construction, can solve problems such as building height restrictions, and achieve the effects of light hoisting weight, improved fatigue resistance and earthquake resistance, and low building height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

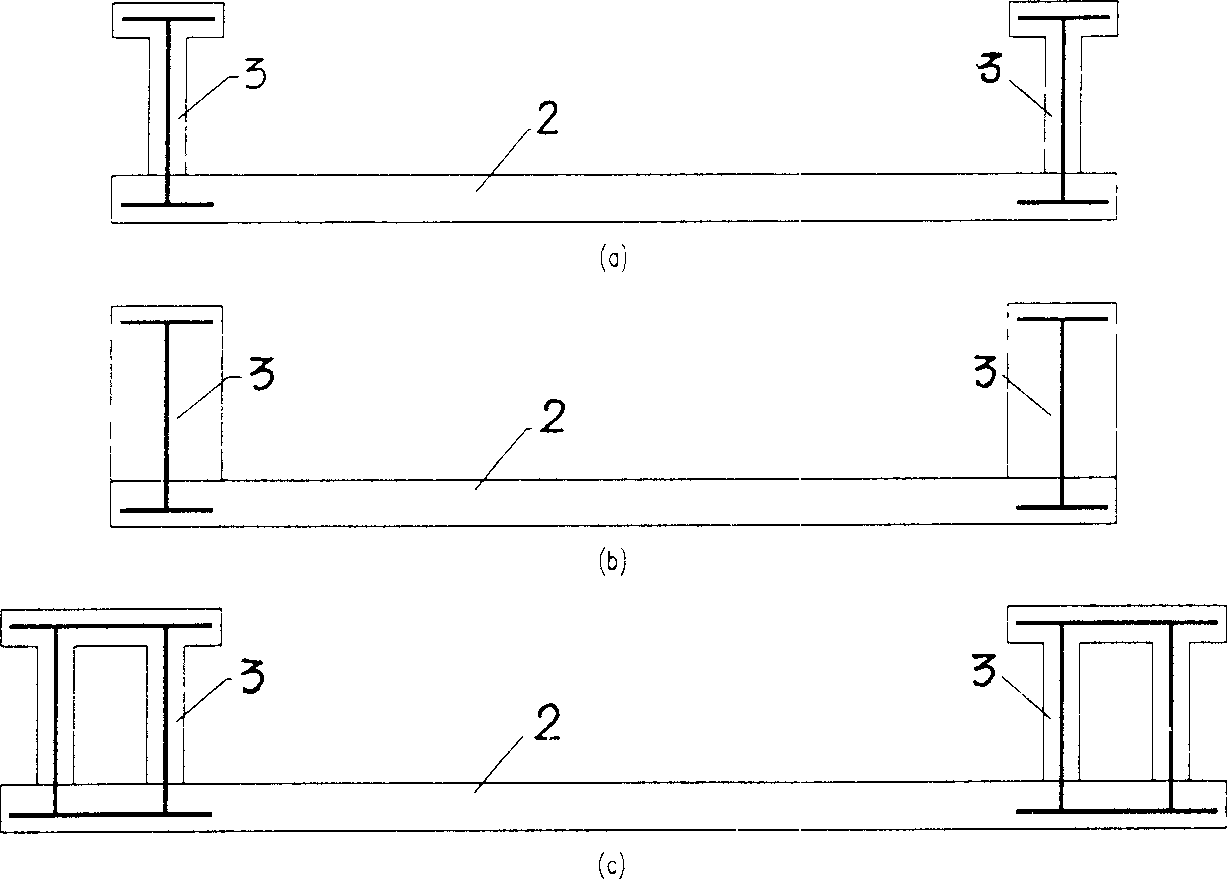

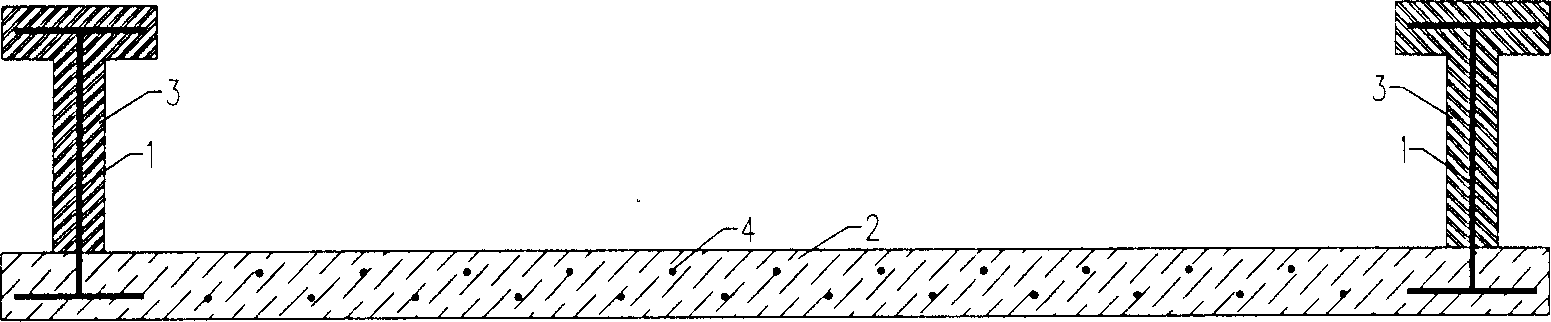

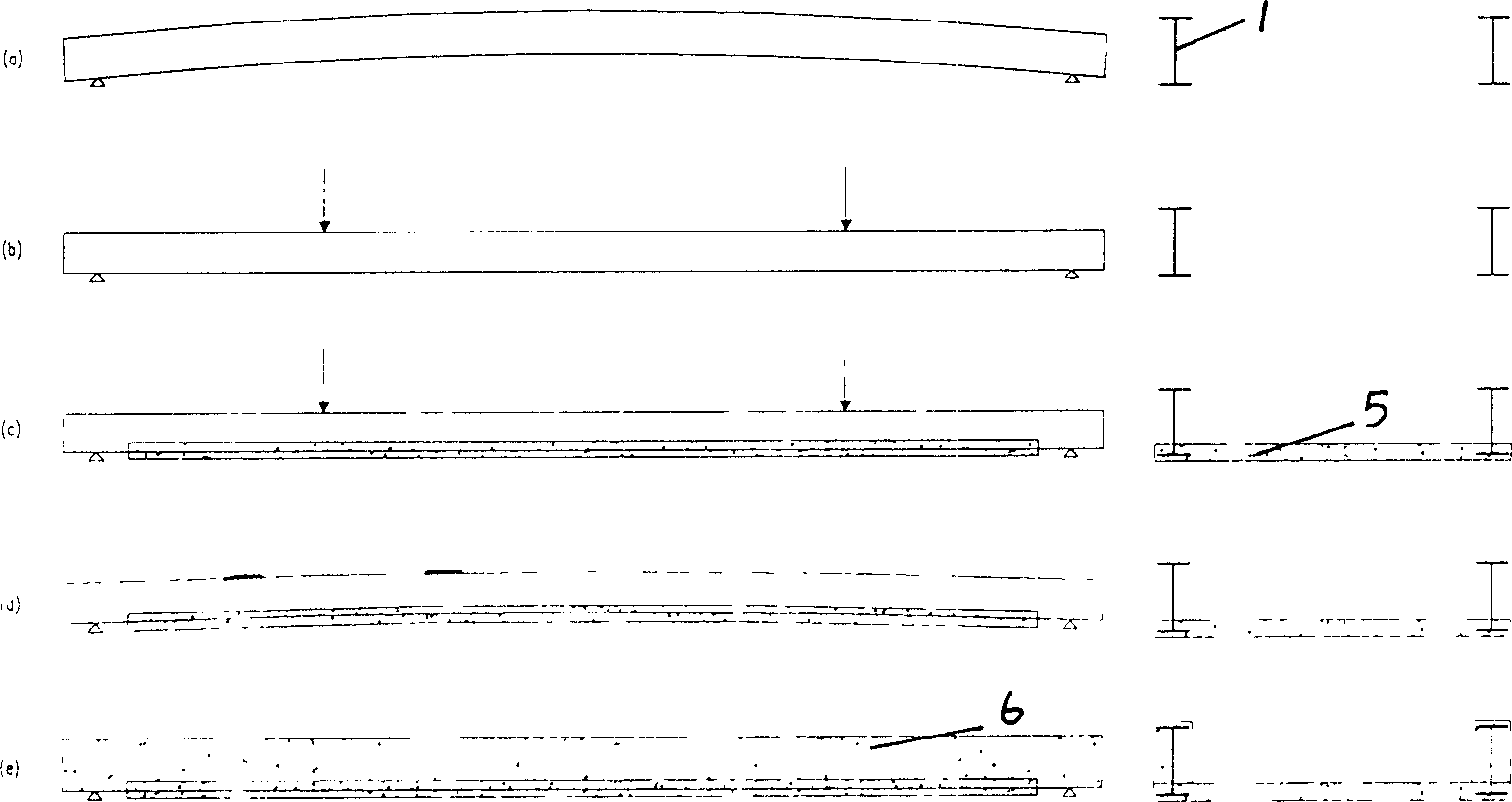

[0012] The present invention is a pre-bent prestressed concrete channel beam, which is different from the prior art in that: the concrete beam is composed of a bottom plate 2 and webs 3 on both sides, and the whole is approximately groove-shaped or U-shaped, and the webs In order to wrap the concrete of the steel beam 1, several shear keys are welded on the steel beam, and the section of the web and the steel beam can be I-shaped, rectangular or box-shaped, and the steel beam is wrapped with the first-stage concrete and the second-stage concrete. For the web, the appropriate web type can be selected according to factors such as force characteristics, vehicle boundaries, and lane layout. For the double-line separated structure, the web should adopt the I-shaped or rectangular shape; for the double-line integral structure, the web should use Box or rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com