Eucalyptus extracts

An extract, eucalyptus technology, applied in the field of plant extracts, can solve the problem of not being able to add

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0026] Production example Preparation of eucalyptus extract

[0027] (Process 1)

[0028] 100 g of dried eucalyptus leaves were crushed, 1000 mL of 50 volume % ethanol aqueous solution was added, extraction was carried out at room temperature for 7 days, and then filtered to obtain 880 mL of eucalyptus extract.

[0029] Evaporation residue: 3.62w / v%

[0030] 1,8-Cineole: 0.2% by weight

[0031] Cypress A: 0.018% by weight

[0032] (1,8-Cineole / Cypress A=11 / 1)

[0033] Evaluation of odor: A fairly strong odor peculiar to eucalyptus was emitted.

[0034] (Process 2)

[0035] The solvent in 100 mL of the above eucalyptus extract was distilled off under reduced pressure, and further dried under reduced pressure to obtain 4 g of eucalyptus extract.

[0036] 1,8-Cineole: 0.25% by weight

[0037] Cypress A: 0.45% by weight

[0038] (1,8-Cineole / Cypress A=1 / 1.8)

[0039] Evaluation of odor: A slight odor peculiar to eucalyptus was emitted.

[0040] (Process 3)

[0041] 4 g ...

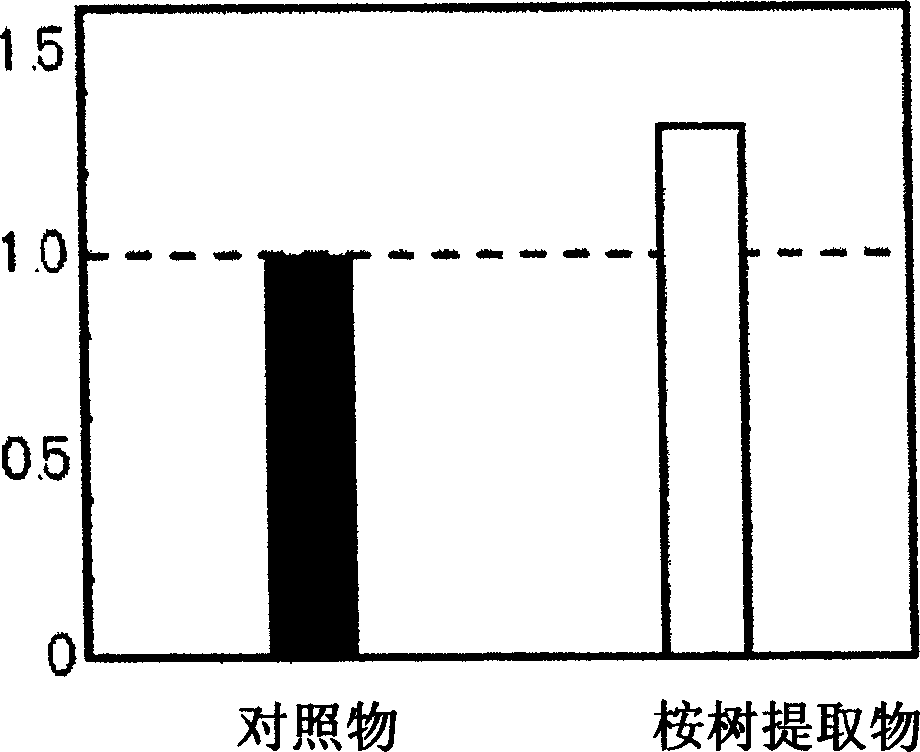

Embodiment 1

[0046] Example 1 Effect of Promoting Ceramide Production

[0047] method

[0048] Using a 6-well plate, containing [ 14 C]-serine (manufactured by Daiichi Chemical Co., Ltd.) culture medium (GIBCO SFM / -BPE, EGF), human keratinocytes (HK-f; manufactured by Kukuto Pharmaceutical Co., Ltd.) at 37 ° C, 5% CO 2Incubate for 24 hours. Then, 0.001% by weight of the eucalyptus extract obtained in Production Example 1 was added in terms of solid content, and further cultured for 24 hours. After removing the culture medium and washing once in PBS, the cells were scraped with a cell scraper and collected in a test tube. After adding 3.6 mL of water, 4 mL of chloroform, and 4 mL of methanol to the human keratinocytes and mixing, the chloroform layer was isolated and dried to solidify. The extracted lipid was developed to the top twice with solvent 1 (chloroform:methanol:acetic acid=190:9:1) on an HPTLC plate [silica gel G60 (20×10cm) Art.5641; manufactured by Melc], and further Solven...

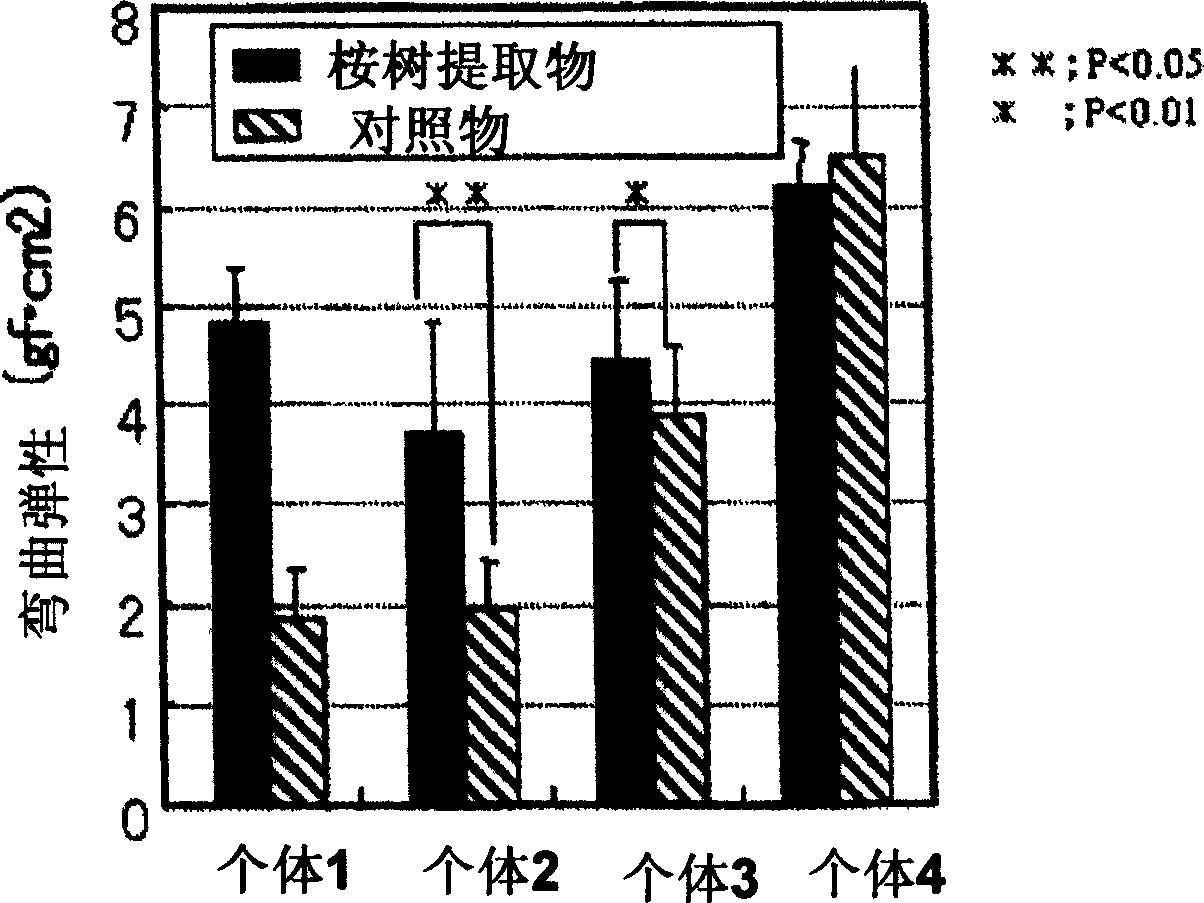

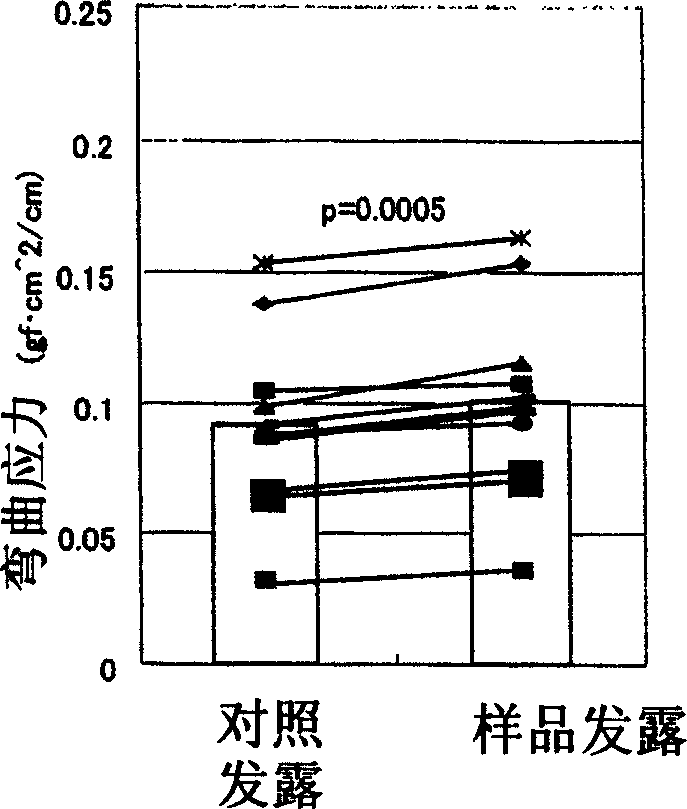

Embodiment 2

[0051] Example 2 Hair Quality Improvement Effect

[0052] Hair quality improvement effects such as softness, tension, elasticity, etc. were evaluated by measuring the bending elastic modulus of woodchuck body hair.

[0053] method

[0054] The body hair of the central part of the back of four groundhogs was shaved, and the central part of the back of the same individual was divided into two regions, the left and the right. A diluted solution of 0.0001% by weight of the eucalyptus extract obtained in the production example and a solvent containing no eucalyptus extract as a control were applied to these two areas, respectively. After 4 weeks, 30 pieces of body hair (about 20 mm in length and about 50 μm in thickness) were cut from the left and right regions to measure the bending elastic modulus. Two stainless steel plates with a length of 40 mm, a width of 15 mm, and a thickness of 0.3 mm were placed at an interval of 5 mm, and 30 body hairs were attached at an interval of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com