Medical film

A medical film technology, applied in medical science, textiles, fabrics, etc., can solve problems such as suturing and fixing difficulties, and achieve the effect of avoiding the reaction of tissues and foreign objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

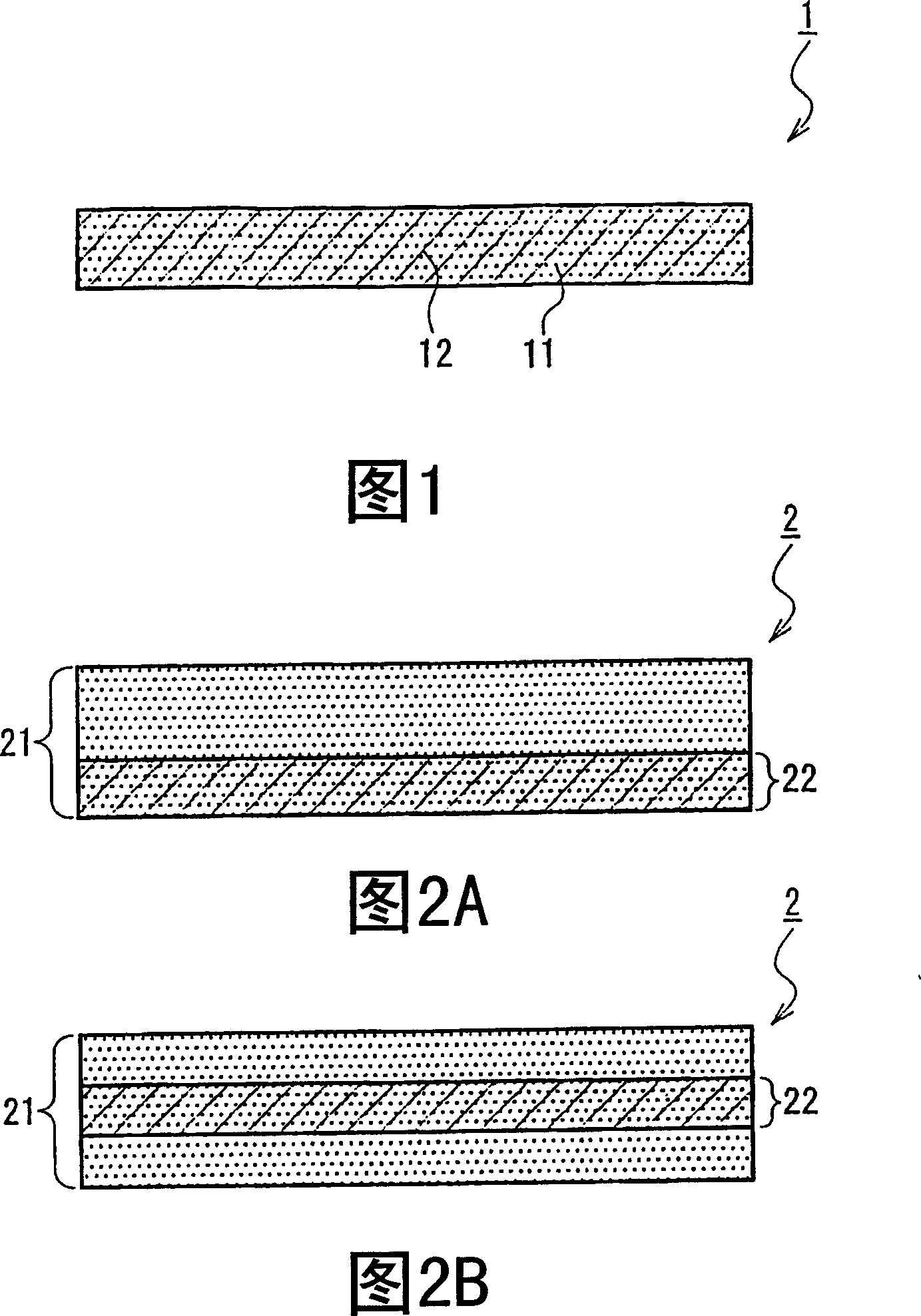

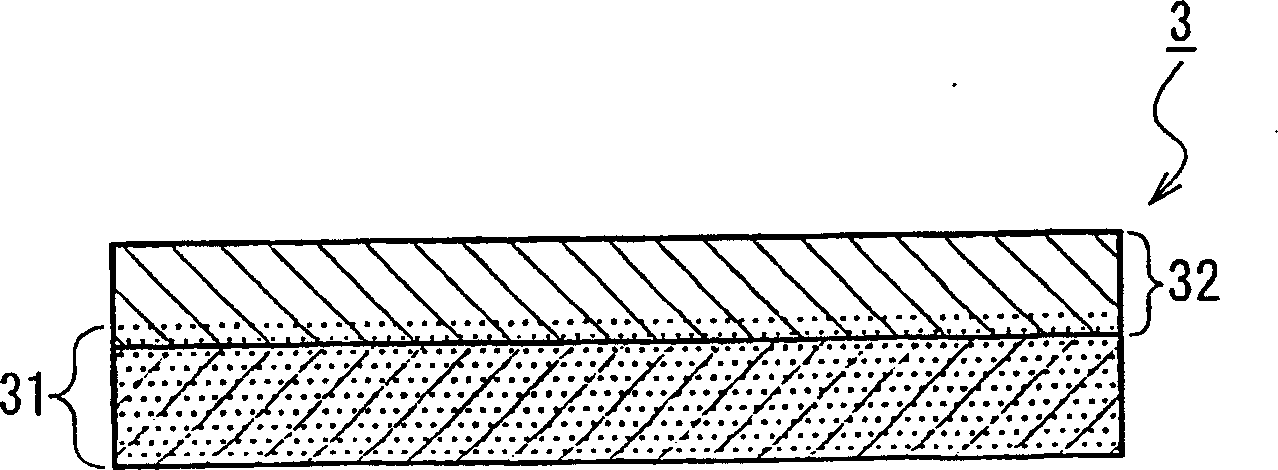

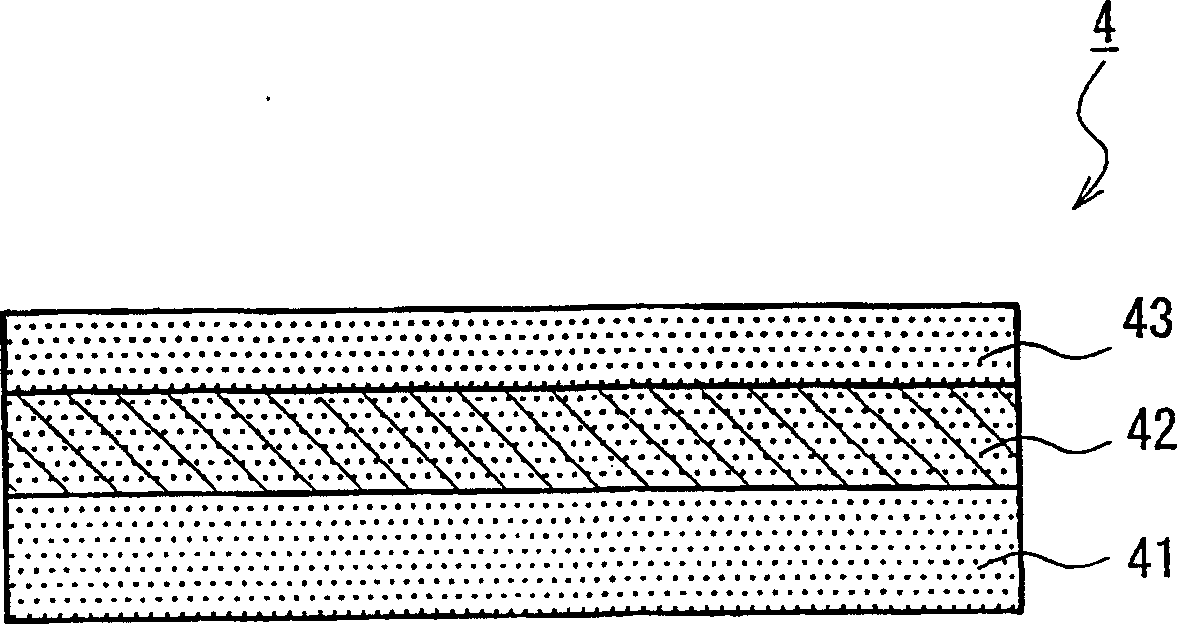

Image

Examples

Embodiment 1

[0110] Fabrication

[0111] Using lactic acid-caprolactone copolymer multifilament (thickness: 42 decitex (dtex)), a double-system braid (thickness 200 μm) with a mesh size of 3.5 mm in both the longitudinal and transverse directions and a mesh size of 3.5 mm in the longitudinal direction was produced. A double-system braid (thickness 200 μm) of 1.5 mm in both directions. Dtex (decitex: 1 decitex=1.111×denier) is an international unit of thickness. As mentioned above, Figure 7 Schematic representation of the fabric weave of the bisystem braid in . This dual-system braid was sandwiched between two glass plates, and vacuum heat-treated at 120° C. for 3 hours. Next, the heat-treated double-ring fabric body was subjected to plasma treatment under the conditions of room temperature, oxygen 67Pa (0.5 Torr), 50W, and 30 seconds.

[0112] Integration with gelatin film

[0113] The various fabric bodies obtained above were cut into rectangles of 9 cm in the longitudinal direc...

Embodiment 2

[0129] As the fabric body, a composite film was produced using a double-system knitted fabric and a warp-knitted fabric shown below, and its strength was determined. In addition, the lactic acid-caprolactone copolymer multifilament used is a lactic acid-caprolactone copolymer in which the composition ratio (molar ratio) of lactide (lactic acid dimer) and caprolactone is 75:25, It is prepared by a known method (see, for example, JP-A-08-317968).

[0130] Reinforcement material

[0131] (double system knit 2-1)

[0132] A lactic acid-caprolactone copolymer multifilament (thickness: 75 decitex (dtex)) was used to produce a double-system braided fabric having a mesh size of 2.7 mm in the longitudinal direction and 3.1 mm in the transverse direction. A photograph of the weaving structure of this double-system braid 2-1 is shown in FIG. 10(A) (25 times enlarged photograph).

[0133] (double system knit 2-2)

[0134] Using a lactic acid-caprolactone copolymer multifilament (thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com