Detection device of corrosion of induction furnace bottom aeration element

A technology for gas supply components and detection devices, which is applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of gas supply components burnout, steel leakage, and difficulty in grasping the erosion rate of gas supply components, and achieves a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

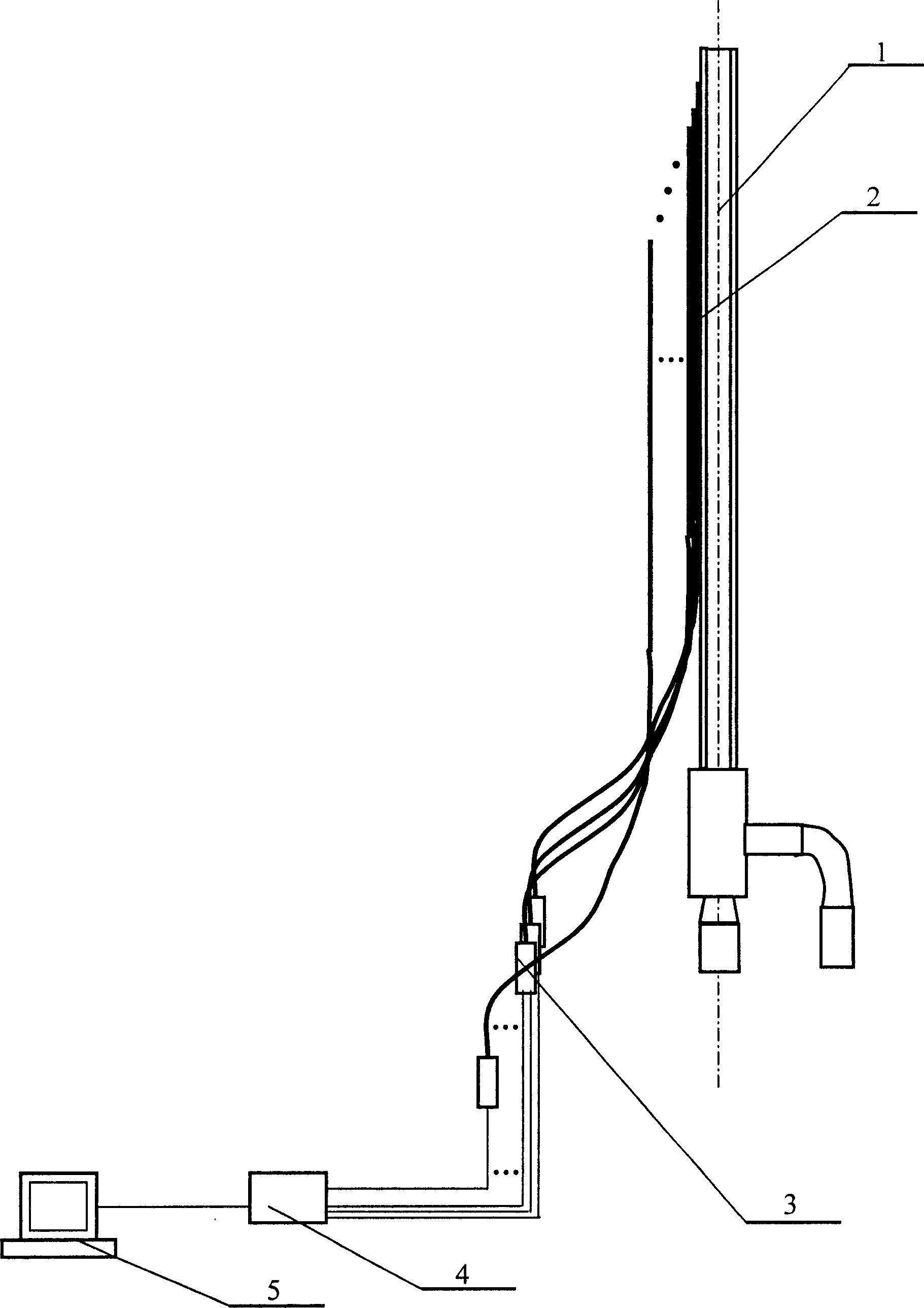

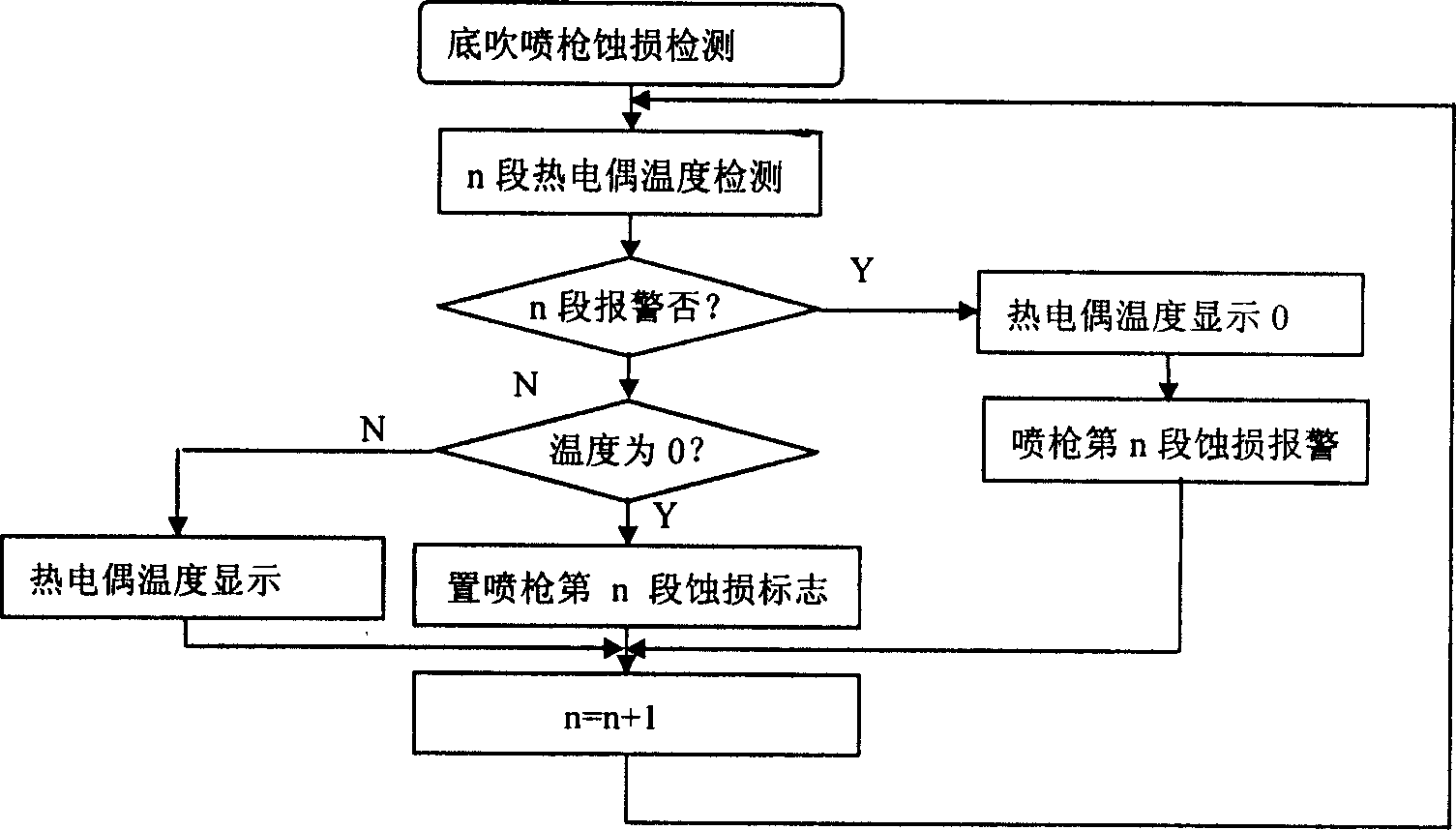

[0011] Such as figure 1 As shown, the number of corrosion detection probes 2 of the induction furnace bottom blowing gas supply element corrosion detection device is 18, which are arranged around the induction furnace bottom blowing gas supply element 1, and are stepped along the direction of the gas supply element to the gas inlet. Arranged, the corrosion detection probe 2 is connected to the transmitter 4 through the connecting plug-in 3, the transmitter 4 is connected to the computer processing system 5, and the computer processing system has an A / D acquisition card. During the smelting process, the corrosion detection probe 2 transmits the measured temperature signal at the corresponding position around the bottom blowing gas supply element 1 to the transmitter 4, and the transmitter 4 converts the weak current signal measured by the corrosion detection probe 2 into The standard signal is transmitted to the computer processing system 5, and the computer processing system 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com