Cutting saw

A saw machine and frame technology, applied in the field of cutting saws, can solve problems such as too loose or too tight saw blades, low work efficiency, and difficulty in ensuring compliance with requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

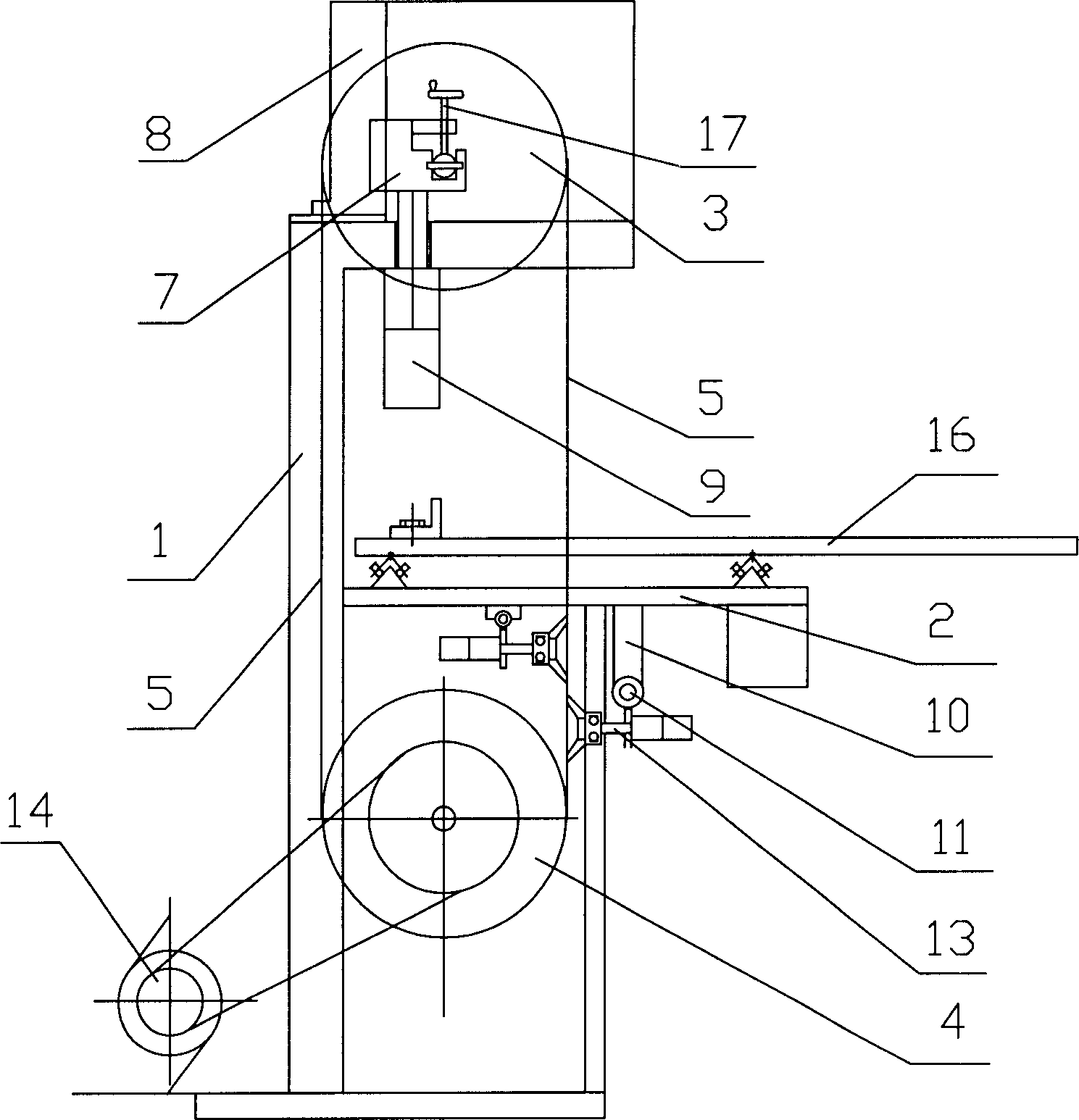

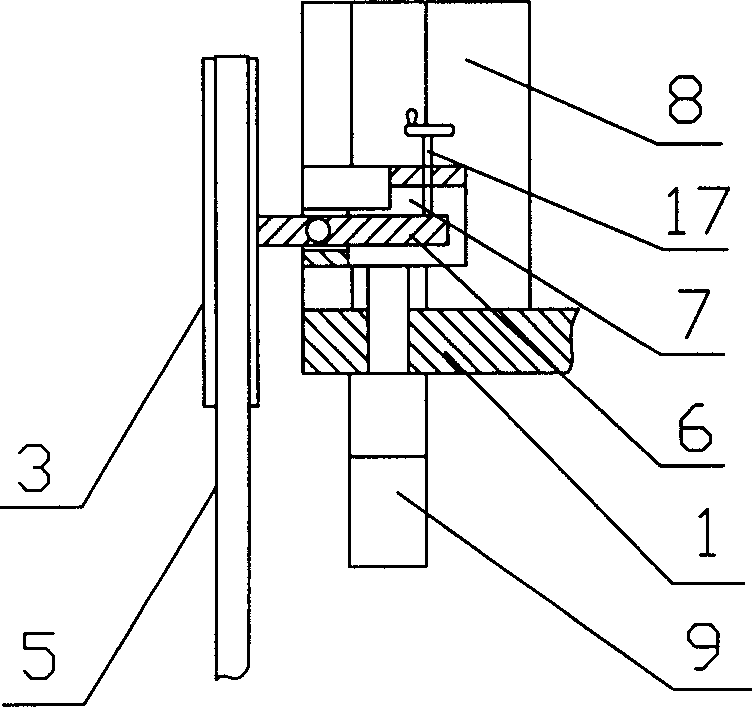

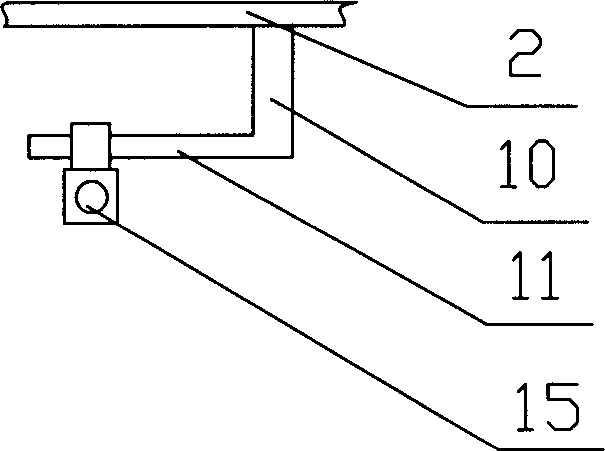

[0018] As shown in the drawings, the cutting saw machine of the present invention includes a frame 1 for supporting various parts; the middle part of the frame 1 has a fixed workbench 2, and a sliding feed plate 16 is placed on the workbench 2 with a pulley During work, the paper roll is placed on the sliding feed plate 16 and sent to the saw blade; the upper end of the frame 1 is equipped with an upper flywheel 3 through the rotating shaft 6; the lower end of the frame 1 is equipped with a lower flywheel 4 connected to the drive motor 14; An annular saw blade 5 is installed between the upper flywheel 3 and the lower flywheel 4; the upper flywheel 3 is installed on the rotating shaft 6, and the rotating shaft 6 is installed on the slide plate 7, and the slide plate 7 is installed in the dovetail groove on the slide plate seat 8, so that the The slide plate seat 8 slides up and down, and the slide plate seat 8 is fixedly installed on the upper end of the frame 1. Sliding plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap