Electronic component mounting apparatus and electronic component mounting method

A technology for installing and comparing devices for electronic components, applied in the direction of electrical components, electrical components, etc., can solve the problems of printed circuit board installation position offset, positioning instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

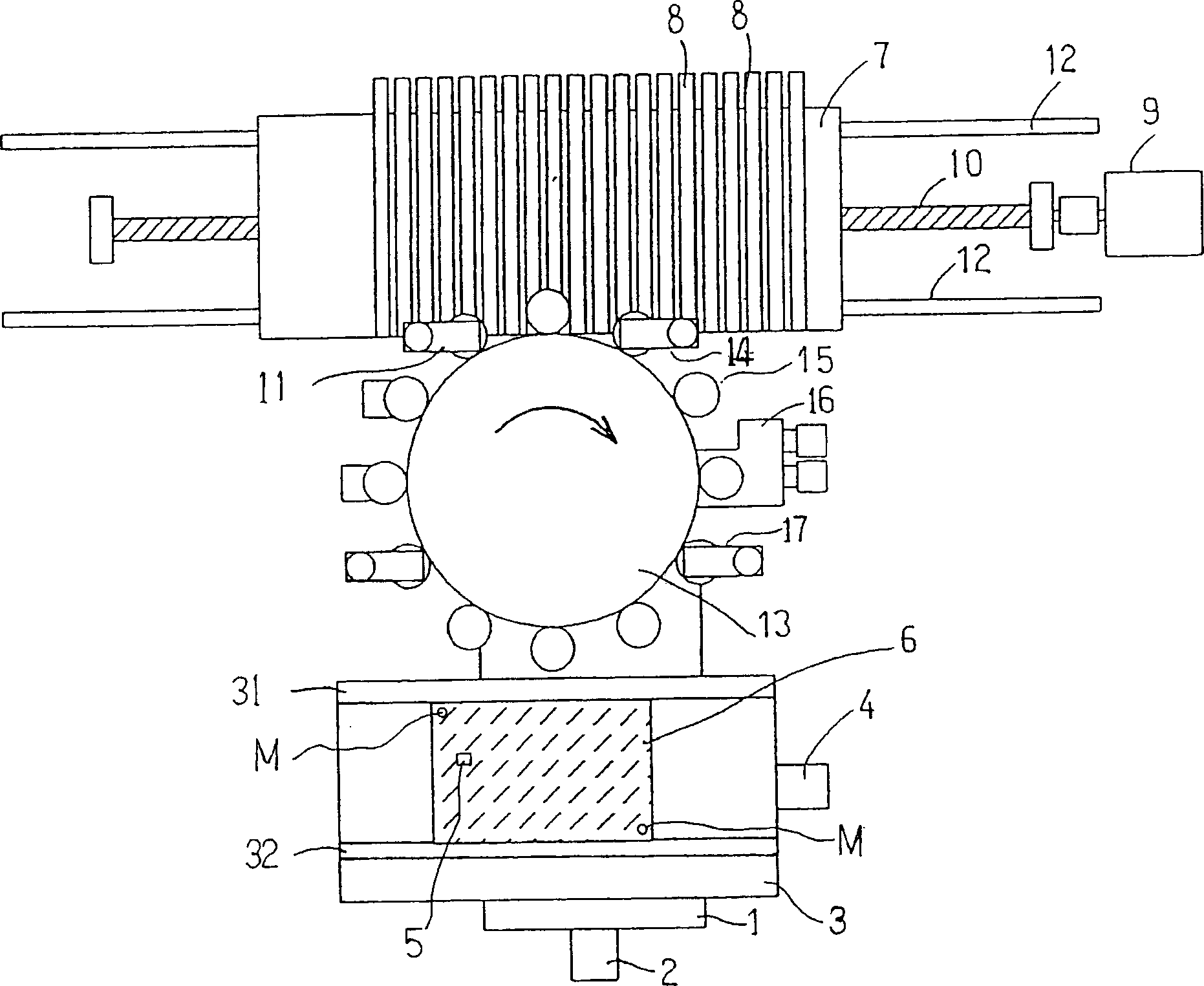

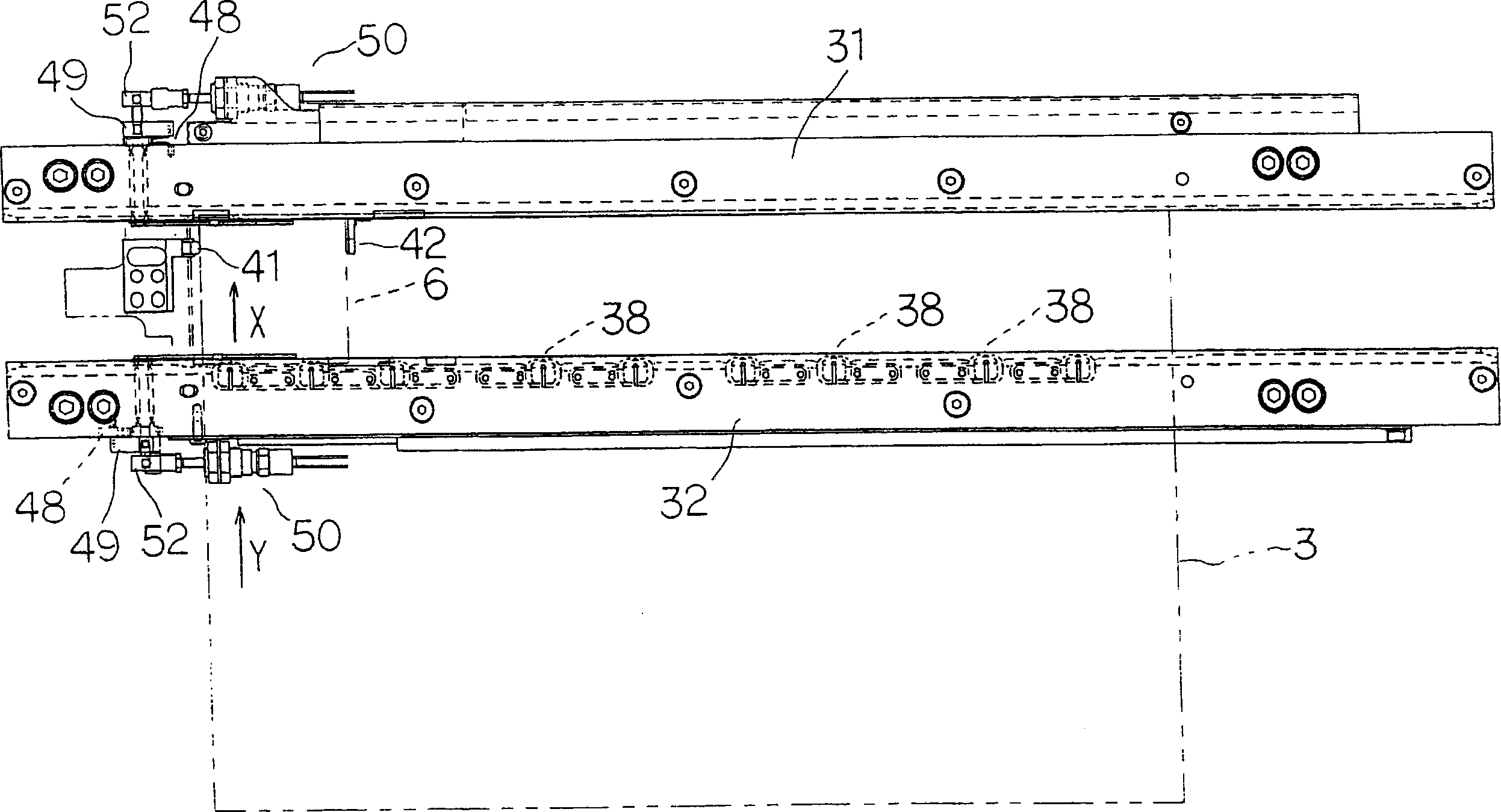

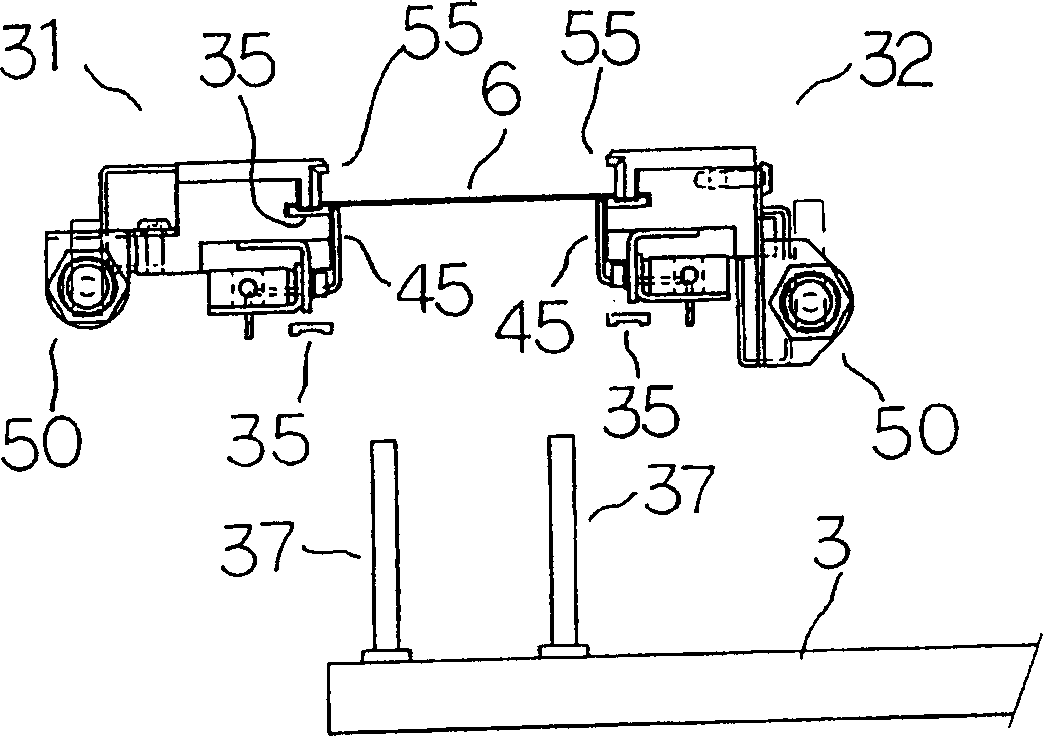

[0031] Hereinafter, an embodiment of an electronic component mounting apparatus for mounting chip electronic components on a printed wiring board will be described in detail with reference to the drawings. Number 1 is the Y stage that moves in the Y direction by the rotation of the Y-axis drive motor 2, and number 3 is the Y stage 1 that moves in the X direction by using the rotation of the X-axis drive motor 4, and finally moves in the XY direction. On the XY mounting table, the printed circuit board 6 on which the chip electronic components 5 (hereinafter referred to as "chip components" or "components") are mounted is fixed by a fixing device not shown, and placed on a pair of conveying slides 31 and 32.

[0032]Numeral 7 is a supply stand, and a plurality of component supply units 8 for supplying sheet components 5 are arranged. Numeral 9 is the supply table driving motor. By rotating the round head bolt 10, the supply table 7 is guided to the supply table 7 on the straight gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com