Liquid level switch by magnetic control

A technology of switch device and magnetic control switch, which is applied in the direction of robot floating motion actuation, can solve the problems of high cost and complexity, and achieve the effects of easy processing and manufacturing, reliable magnetism, and simple sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

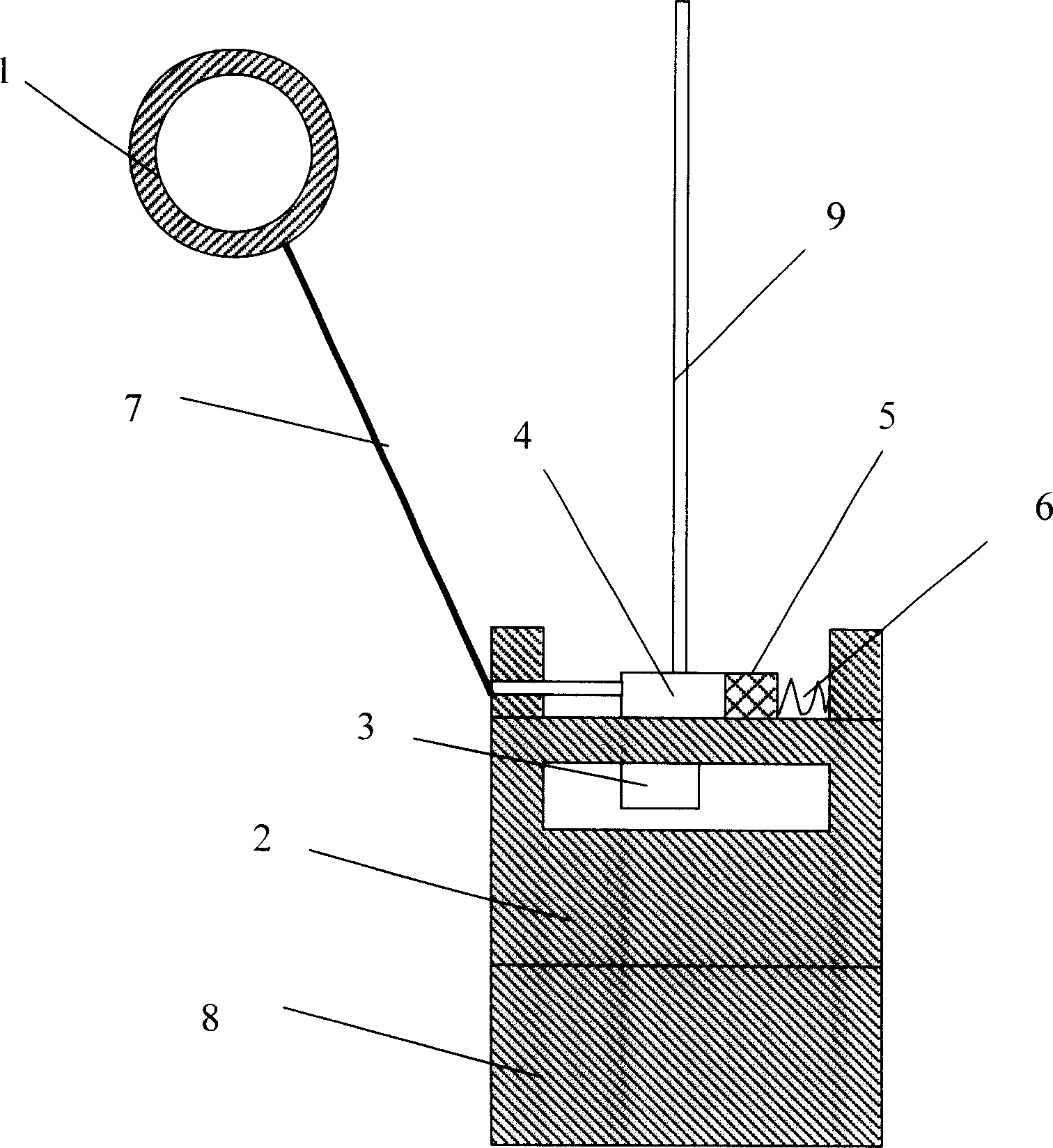

[0011] Such as figure 1 As shown, a magnetically controlled liquid level switch device of the present invention is composed of a float 1 and a sealed plastic shell 2, wherein a magnetic switch 3 is provided in the plastic shell 2, and the plastic shell 2 A chute is provided on the outer side of the upper end, a plastic slider 4 is provided in the chute, a magnet 5 is sealed in the plastic slider 4, and one end of the plastic slider 4 passes through an elastic element 6 is fixedly connected to the plastic housing 2, the other end of the plastic slider 4 is connected to the float 1 through a connecting strap 7, and the magnetic control switch 3 is connected with a wire, and the The wire is arranged in a sheath 9, and the sheath 9 is sealed with the plastic shell 2.

[0012] Further, the magnet is made of neodymium iron boron material.

[0013] Further, the lower end of the plastic shell 2 is provided with a counterweight 8.

[0014] Further, the elastic element 6 is a spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com