Valve device

A valve device and connecting device technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of valve device manipulation and adjustment characteristics, inaccurate determination of valve element position, high dynamic movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

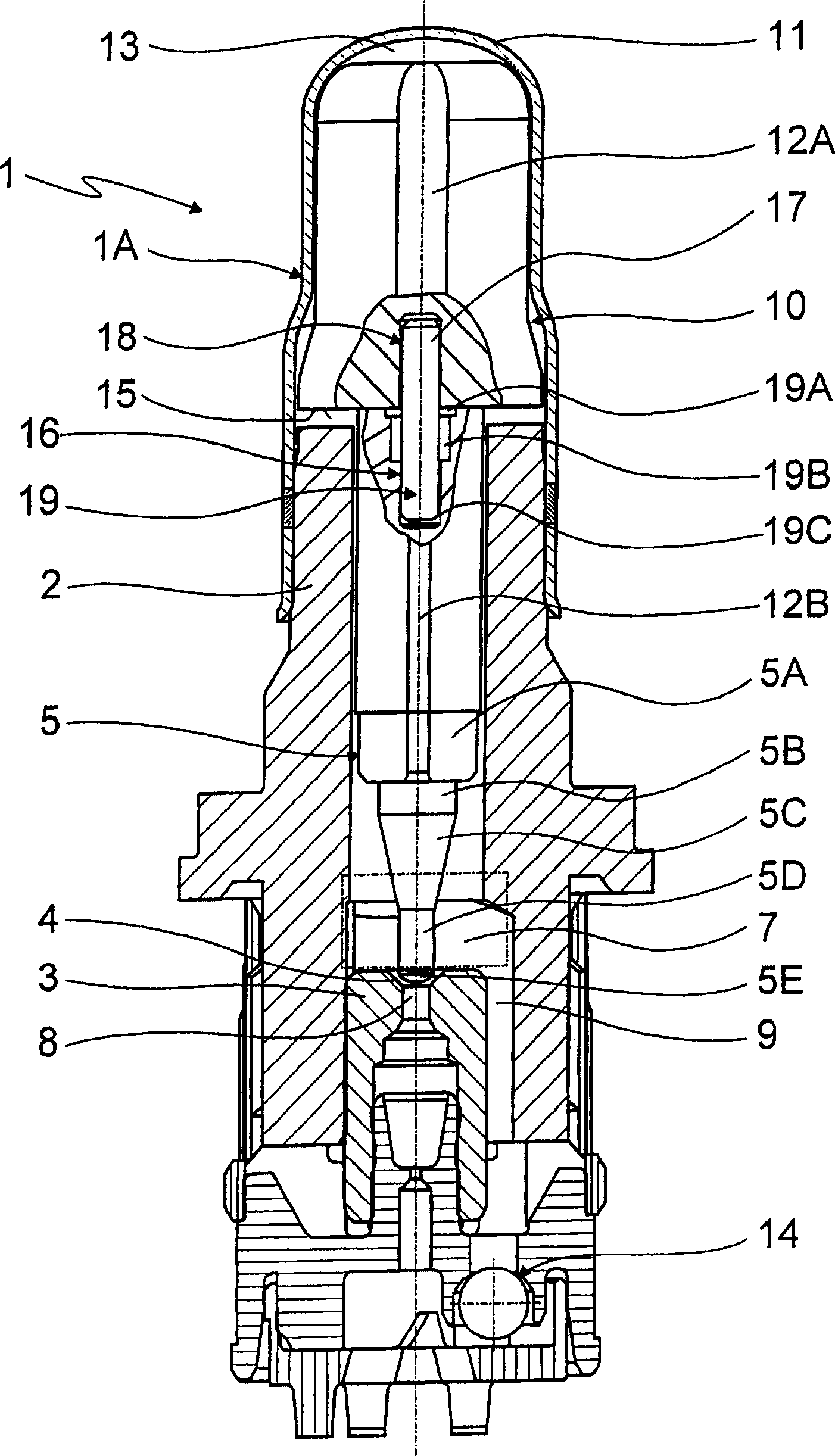

[0016] The figure shows a part of the electromagnetically operable valve device 1 in a simplified longitudinal section. The valve device 1 has a valve element 5 that can move longitudinally in the valve bushing 2 and cooperates with a valve seat 4 formed in the valve body 3.

[0017] The area of the valve element 5 facing the valve seat 4 is located in the valve cavity 7 defined by the valve bushing 2 in the area of the valve seat 4, wherein the outline size of the valve cavity is further shown by the rectangle drawn with a dashed line in FIG. 1. The area of the valve element 5 facing the valve cavity 7 has a first cylindrical area 5A, a second cylindrical area 5B resting on the cylindrical area 5A and having a reduced diameter, and a conical area 5C connected to the second cylindrical area 5B , The third cylindrical area 5C connected to the conical area 5C and the dome-shaped area 5E connected to the third cylindrical area 5D.

[0018] The dome-shaped area 5E of the valve e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com