Foundation construction of precast concrete pipes

A technology of concrete foundation and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of long construction period, difficult quality control, low work efficiency, etc., and achieve the effect of shortening construction period, easy quality control and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

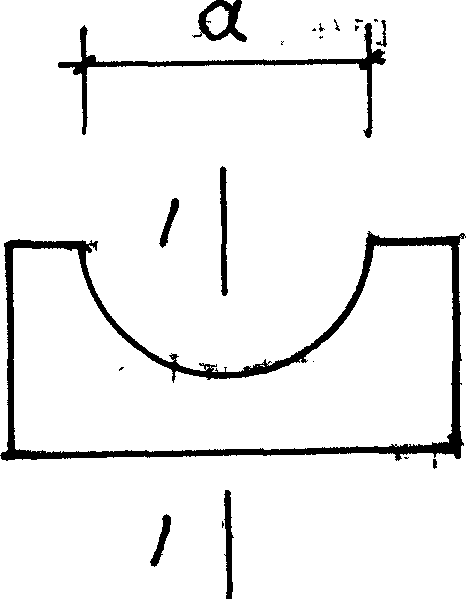

[0021] In Fig. 1 and Fig. 2, the precast concrete support according to the illustrated size is transported to the site for installation when it reaches 70% of the concrete design strength. In Fig. 1, a=design chord length+40mm.

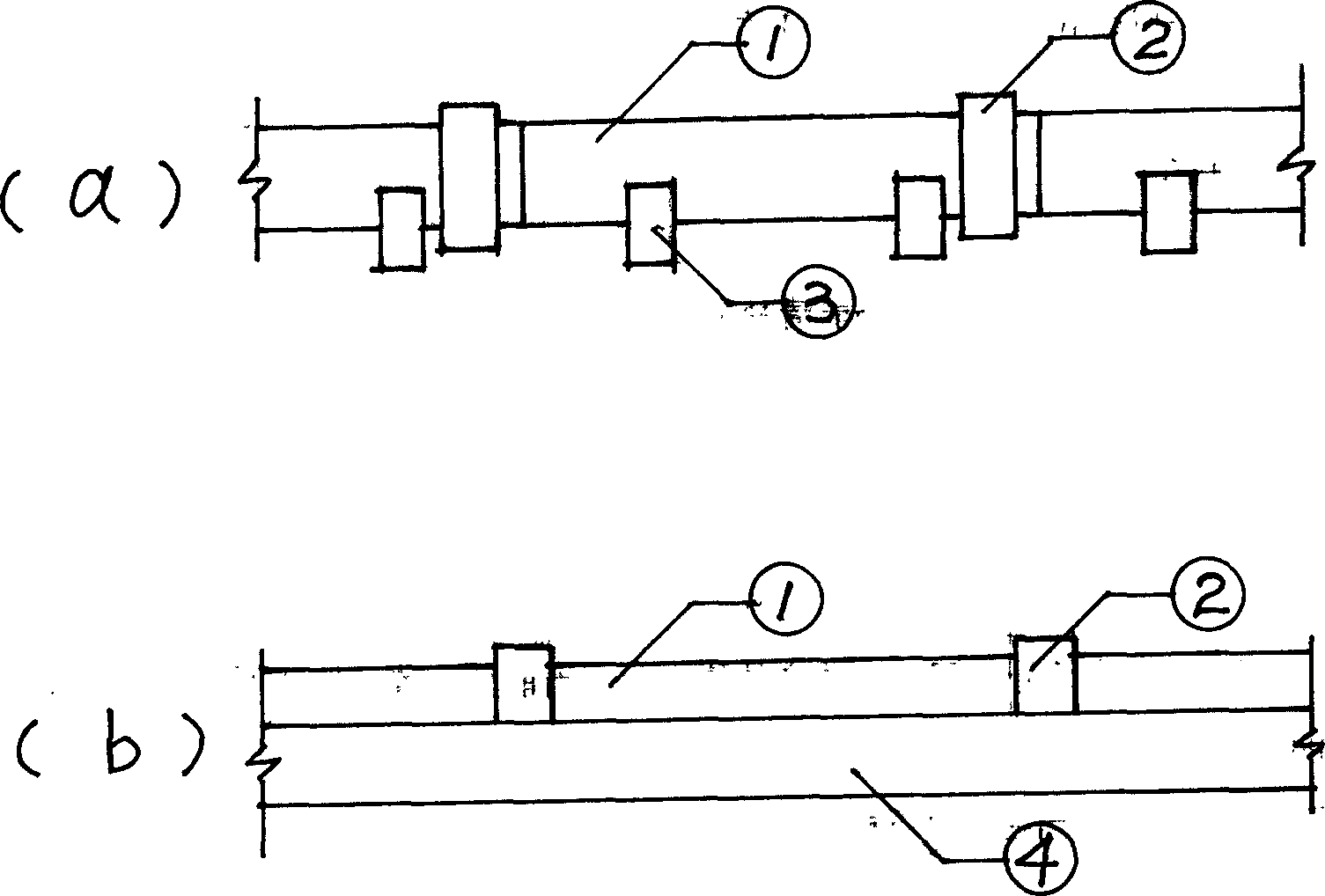

[0022] In Figure 3(a), the prefabricated support ③ is placed according to the design elevation, axis and position of the pipeline, and then the prefabricated pipe ① is placed on the support ③, and the casing ② is sleeved on the prefabricated pipe ①. Repeat the job one by one. In Figure 3(b), straighten the prefabricated pipe ① to find the slope, and cut the prefabricated pipe ① and casing ②. After the closed water test is qualified, the entire pipeline foundation ④ is cast. The formwork is supported at one time, and the concrete pouring is also completed at one time, leaving no horizontal construction joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com