Micro-path parallel current heat-exchanger for transcritical Co2 circulation and mfg. method

A technology of parallel flow heat exchanger and manufacturing method, applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problem that welding quality is not easy to control, the yield of heat exchanger is reduced, and the temperature is uneven and other problems, to achieve the effect of easy control of welding quality, improved yield and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings.

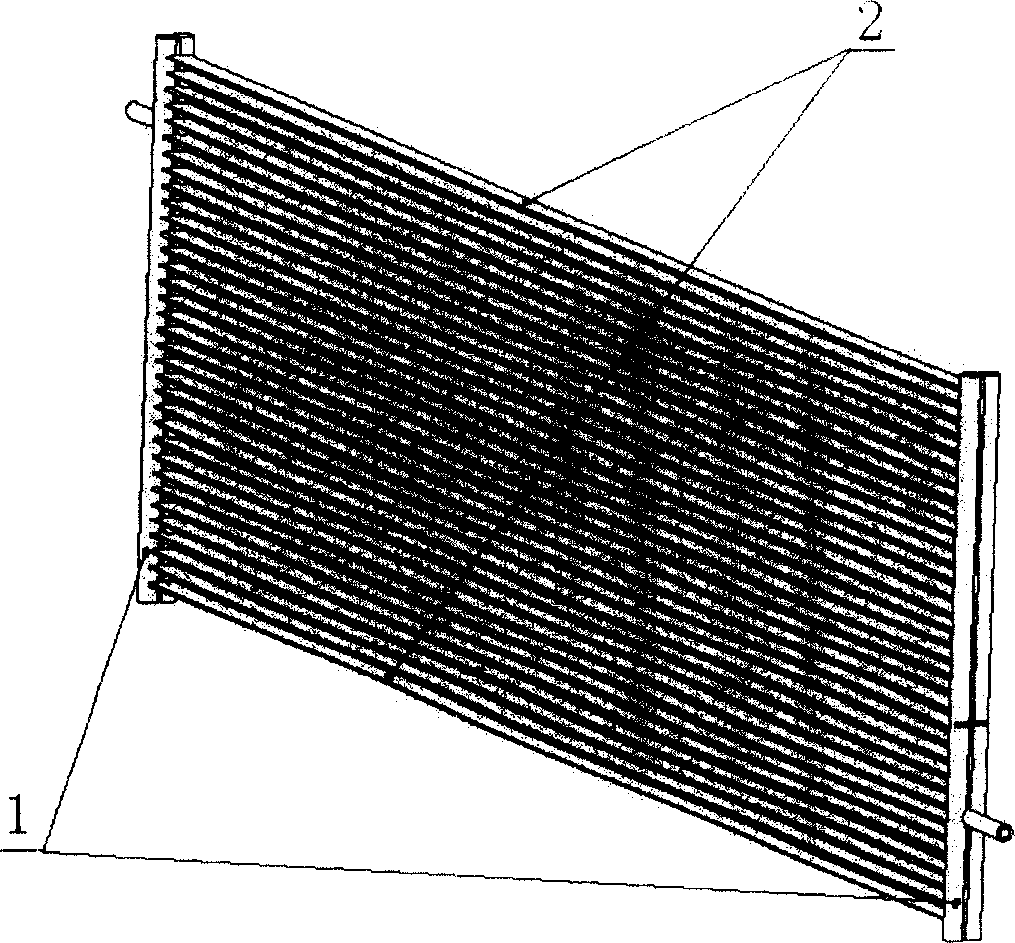

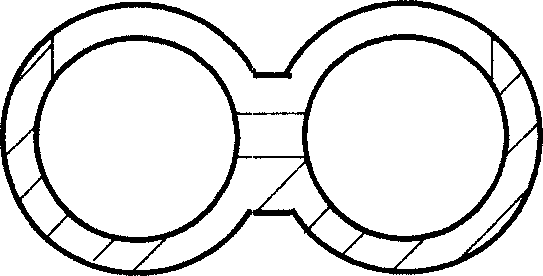

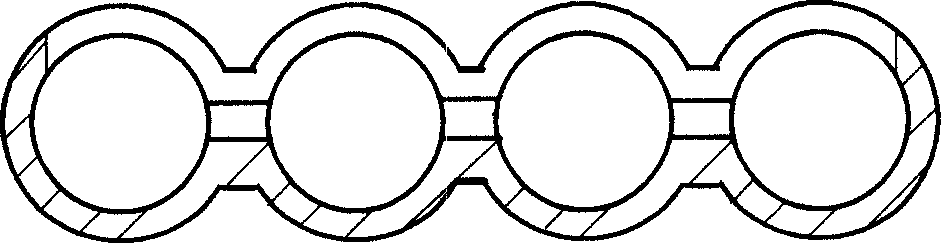

[0022] Figure 5 The schematic diagram of the three-dimensional structure of the microchannel parallel flow heat exchanger provided by the present invention, the microchannel parallel flow heat exchanger contains a multi-tube header 1, a heat exchange flat tube bundle 2 welded between the two headers, and a parallel flat tube bundle 2. Fins 3 are welded between the tube bundles. Image 6 a is a schematic cross-sectional structure diagram of the multi-tube header provided by the present invention, one side of which is designed as a plane and formed by extrusion; in order to be welded with the flat tube bundle, a flat tube having a flat tube thickness and width is milled out on the welding plane in parallel. Hot flat tube slot 4 ( Image 6 b).

[0023] CO 2 The working medium first enters the multi-tube header 1 (inlet header...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com