An electrostatic paste hook base assembly structure and a suspended tray structure

An assembly structure and electrostatic paste technology, which can be applied to other household appliances, household components, household appliances, etc., can solve the problems of inseparability, air ingress, and falling, so as to avoid potential safety hazards, ingenious structural design, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

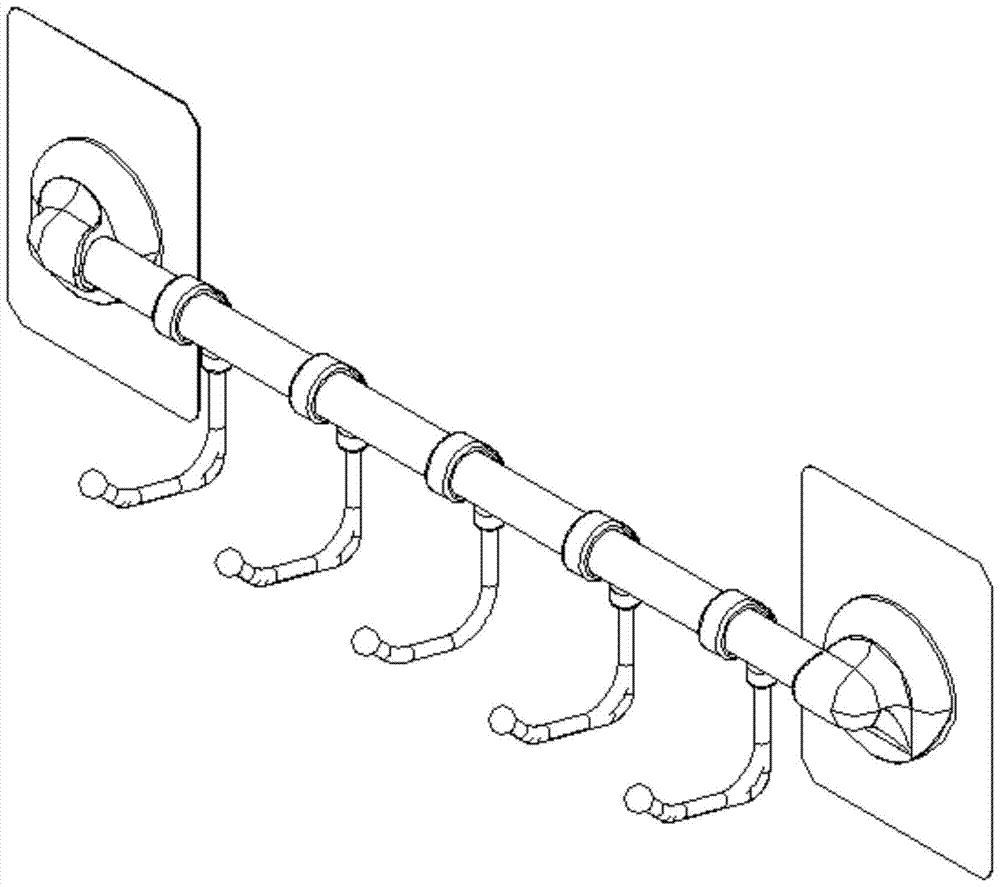

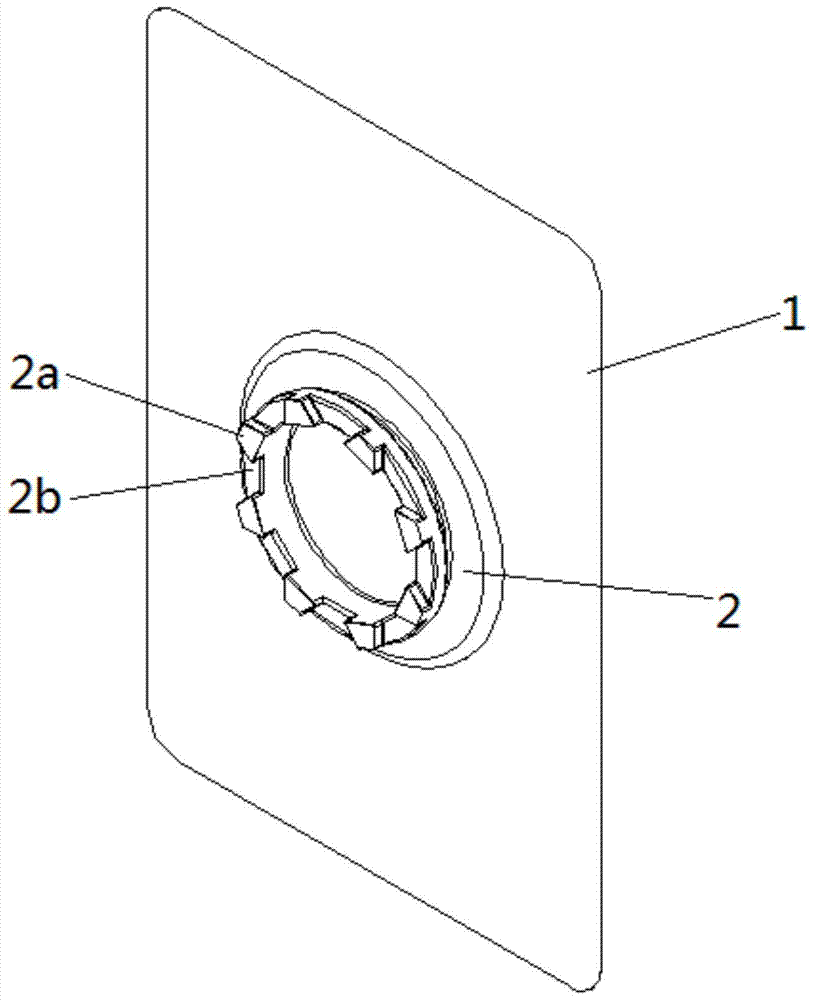

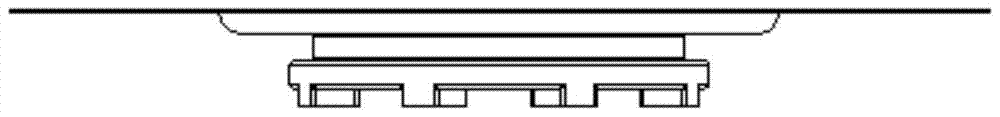

[0044] see Figure 1-Figure 15 , an electrostatic paste hook base assembly structure, including a square soft transparent electrostatic film 1, a hook mother part 2, and a hook sub-part 3; the square soft transparent electrostatic film 1 and the hook mother part 2 are welded together; the hook The parent part 2 is circular, with a protruding structure on its upper ring, and N trapezoidal bosses 2a are equidistantly arranged on the ring-shaped raised structure, N is an even number, and N≥4; an inverted circle is formed between adjacent bosses 2a Trapezoidal notch 2b, the large end of the trapezoidal boss 2a faces inward, and the large end of the inverted trapezoidal notch 2b faces outward; the middle part of the hook component 3 has a piece for inserting into the inverted trapezoidal notch 2b The matching main rib 3a, the main rib 3a is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com