Garnett machine

A technology of opening machine and rough opening, which is applied in deburring devices, textile and paper making, fiber processing, etc., which can solve the problems of waste, redundant overall structure, and increased equipment cost, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

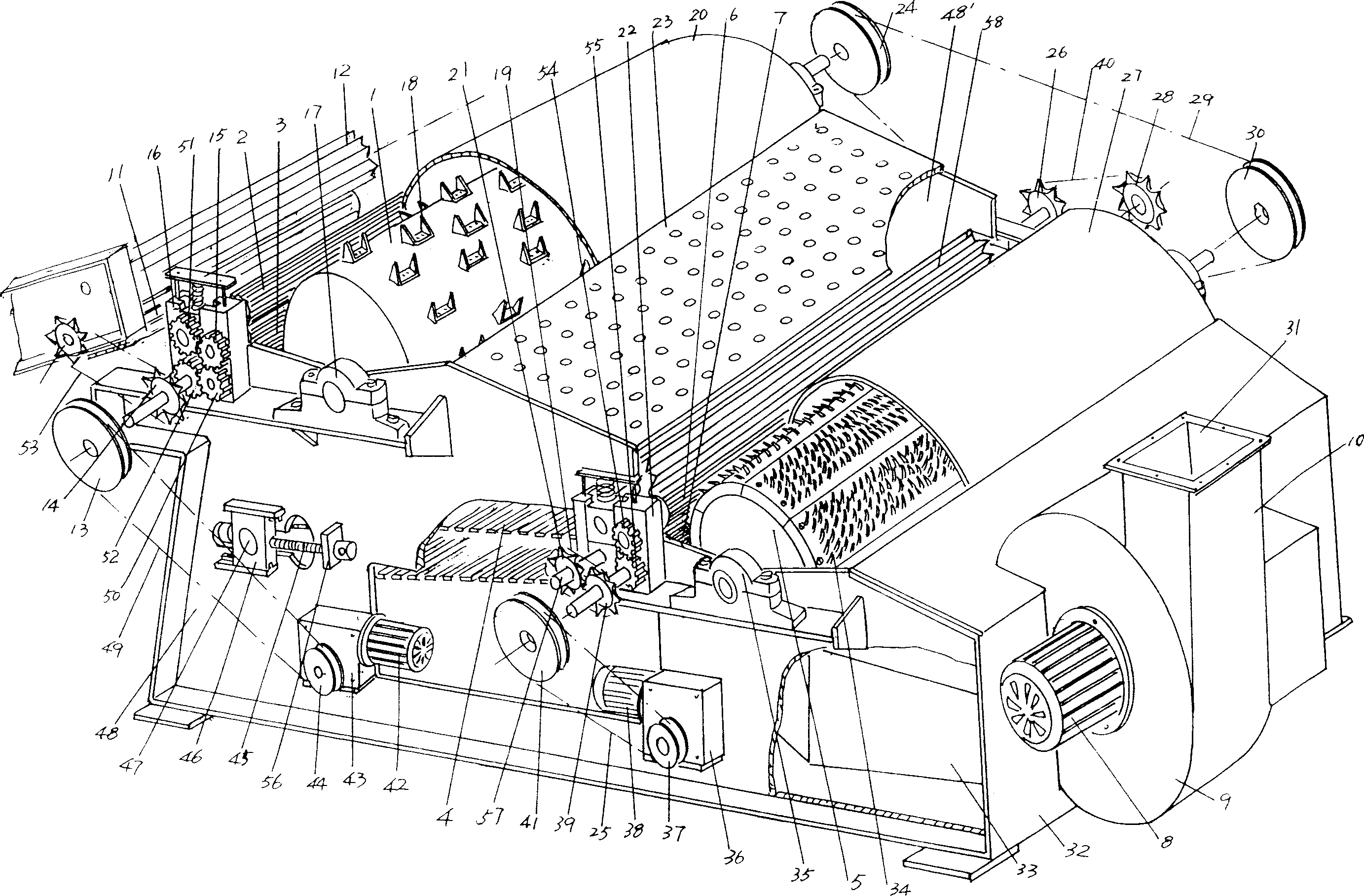

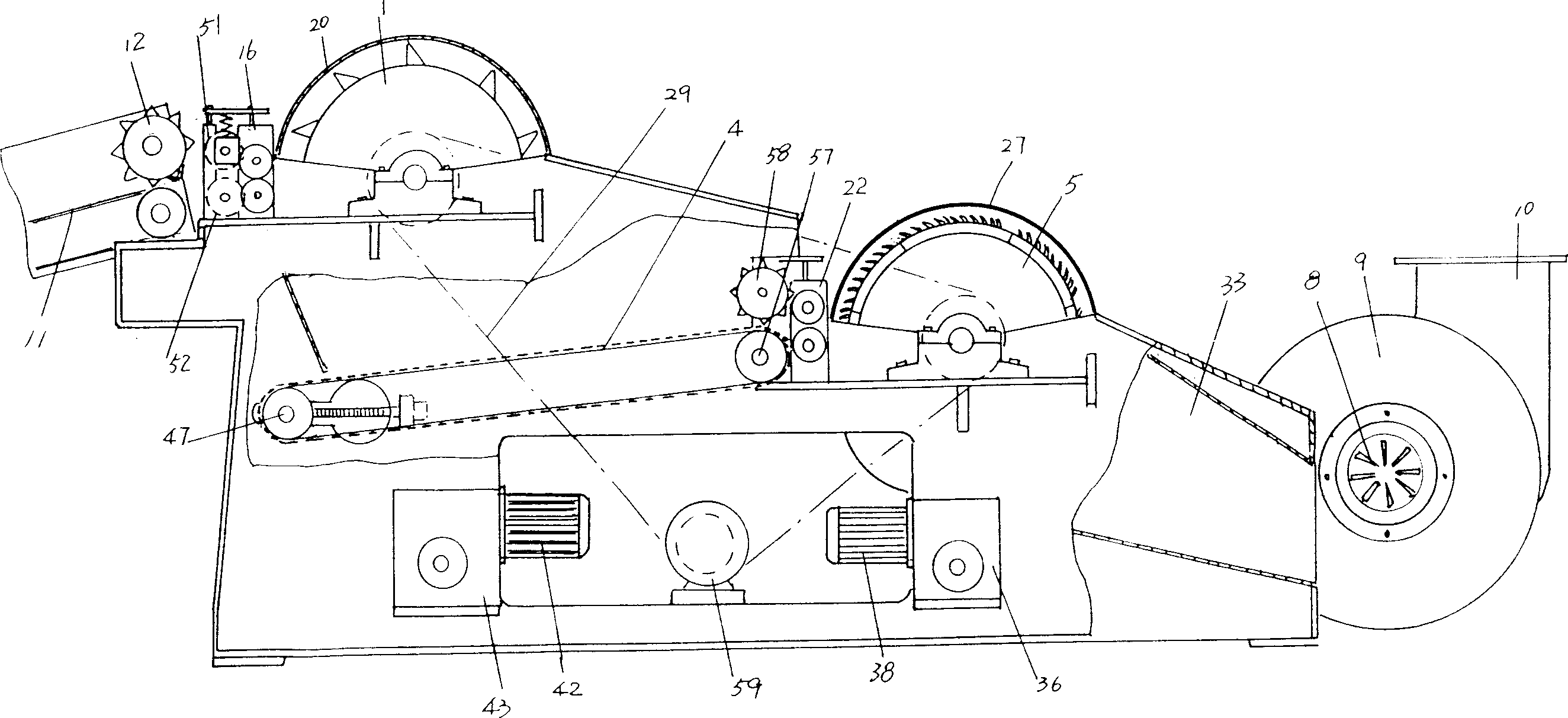

[0021] please see figure 2 and image 3 , frame wall panels 48, 48 ' are customarily referred to as front and rear wall panels, both of which have the same shape, one end of the frame wall panels 48, 48 ' is as high as the left end of the position shown in the figure, and the other One end, namely the right end of the position shown in the figure, is low, that is to say, the end equipped with the pre-opening mechanism is higher than the end equipped with the fine opening mechanism. The side portion of the rightmost end of a pair of frame wallboards 48, 48' is connected by a sealing plate 32, and extends to the right in the lower direction corresponding to the fine opening and loosening roller 5 of the fine opening and loosening mechanism. The finely opened and loosened fibers are led to the cotton bucket 33 of the passage of the cotton outlet mechanism.

[0022]A pair of first roller shaft seats 16 are respectively vertically fixed at the high-end positions of the frame wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com