Optical multiplexer/demultiplexer and production method for optical multiplexer/demultiplexer

A wave splitter and optical multiplexing technology, applied in light guides, optics, instruments, etc., can solve problems such as difficulty in reducing costs, inability to improve production efficiency, and complicated manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

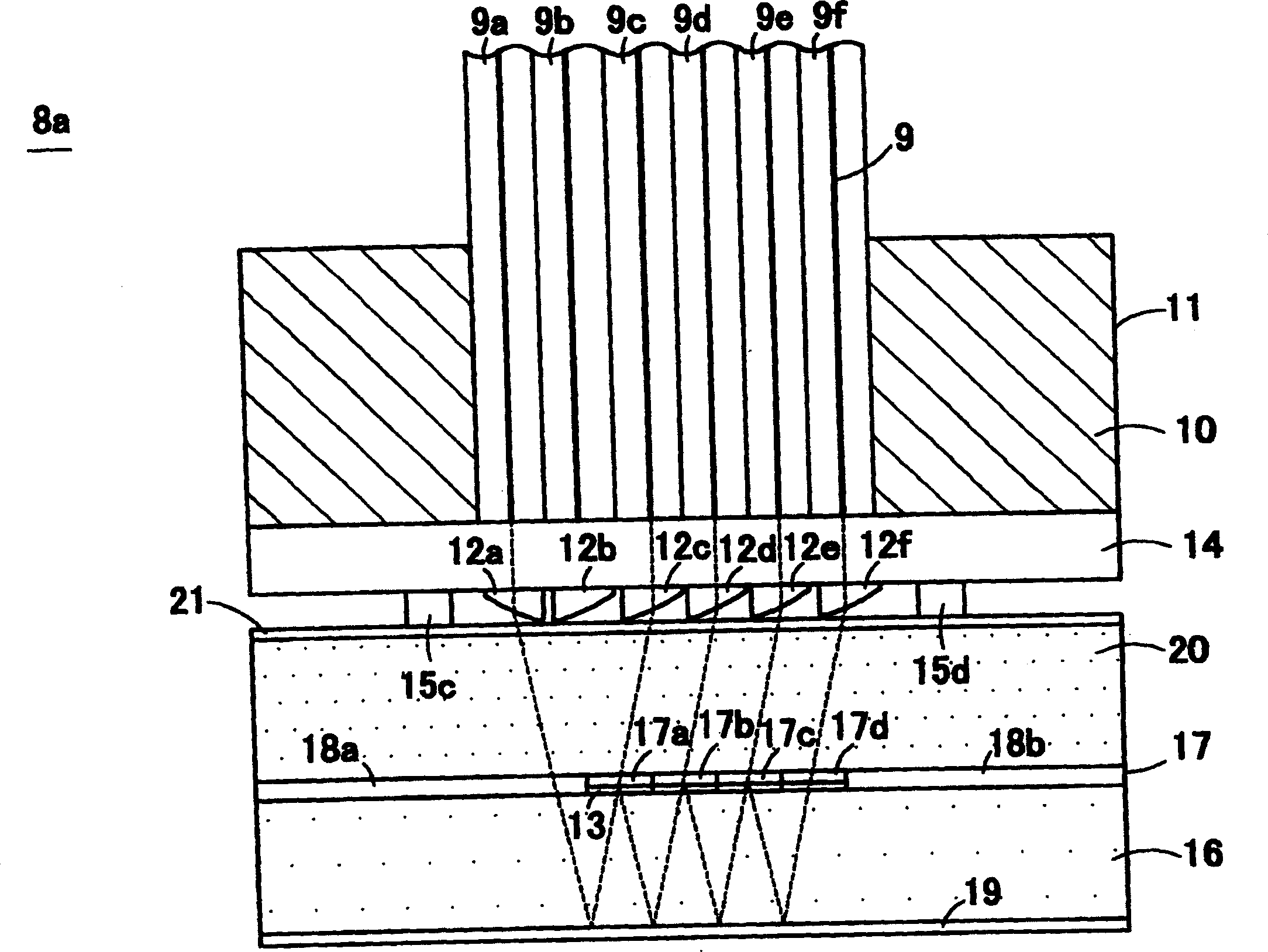

[0134] figure 2 It is a schematic exploded perspective view showing the structure of the optical multiplexer / demultiplexer 8a according to Embodiment 1 of the present invention. image 3 is through figure 2 The shown schematic cross-sectional view in the plane of the core 9 of the optical fibers 9a-9f of the optical multiplexer / demultiplexer 8a illustrates the state of wave-multiplexing or multiplexing. in addition, Figure 4 yes means figure 2 A schematic side view of the optical combiner / demultiplexer 8a shown. First, explain Figure 2-Figure 4 The structure of the optical combiner / demultiplexer 8a of the present invention is shown.

[0135] Optical multiplexer 8a of the present invention is made of transparent cover member 20 such as optical fiber array 11, microlens array 14, glass plate, spacer 15a, 15b, 15c, 15d, filter layer 17, light guide block 16, plane mirror layer 19 constitute. Here, in the optical fiber array 11, the optical fibers 9a, 9b, 9c, 9d, 9e, a...

Embodiment 2

[0176] Fig. 17 is a partial schematic sectional view of the optical multiplexer / demultiplexer 8b according to Embodiment 2 of the present invention, which is equivalent to that described in Embodiment 1. Figure 14 diagram. The optical filters 17a, 17b, 17c, 17d, and 17e are dielectric multilayer films that transmit light of wavelengths λ1, λ2, λ3, λ4, and λ5, respectively. The optical filter layer 17 is composed of a region composed of optical filters 17a-17e and a release film 13, and dummy films (spacers) 18a, 18b. The filter layer 17 can be manufactured by the manufacturing steps described in Embodiment 1. In the optical multiplexer / demultiplexer 8b shown in FIG. 17 , the description of the same configuration as that described in the first embodiment is omitted.

[0177] The optical combiner / demultiplexer 8b of this embodiment covers the surface of the filter layer 17 with a transparent, very thin film 20a such as glass to protect the filters 17a-17e from moisture. An A...

Embodiment 3

[0182] Fig. 19 is a partial schematic cross-sectional view of an optical multiplexer / demultiplexer 8c according to Embodiment 3 of the present invention, which is equivalent to that described in Embodiment 1. Figure 14 diagram. In the optical multiplexer / demultiplexer 8c shown in FIG. 19, the description of the same configuration as that described in Embodiment 1 is omitted. The filter layer 17 is composed of filters 17a-17e, a release film 13, and a dummy film 18a. The filter layer 17 can be produced by the production method described in Example 1. The optical filters 17a, 17b, 17c, 17d, and 17e are dielectric multilayer films that transmit light of wavelengths λ1, λ2, λ3, λ4, and λ5, respectively. In order to adjust the height of the microlens array 14 , spacers 31 a and 31 b are interposed between the light guide block 16 and the microlens array 14 .

[0183] In the optical multiplexer / demultiplexer 8c of this embodiment, a transparent adhesive is applied to a transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com