Multifunctional energy-saving coating for building

A multi-functional, film-coating technology, applied in the field of chemical building materials, can solve the problem of low thermal insulation function, and achieve the effect of strong thermal insulation function, reduced running time and good environmental protection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1, embodiment (weight %)

[0025] Waterborne synthetic resin film-forming substance 15~45

[0026] Thermal insulation functional material 5~25

[0027] Pigment 5~25

[0028] Filling 5~25

[0029] Auxiliary 1~5

[0030] PH regulator 0.1~1

[0031] Water 20~40

[0032] 2. Preparation process

[0033] (1) Add part of water, part of additives, part of water-based synthetic resin film-forming substance into the dispersion kettle and disperse evenly;

[0034] (2) Add pigments and fillers to (1) and grind to disperse evenly;

[0035] (3) Add (2) into the paint mixing kettle, then add the heat-insulating functional material, the remaining water, the remaining additives, and the remaining water-based synthetic resin film-forming substances, and mix them evenly;

[0036] (4) Add pH regulator in (3), adjust PH=8~9, allot evenly;

[0037] (5) Filtering, measuring, and packaging (4) is the product (finished) of the present invention.

[0038] 3. Implementation method

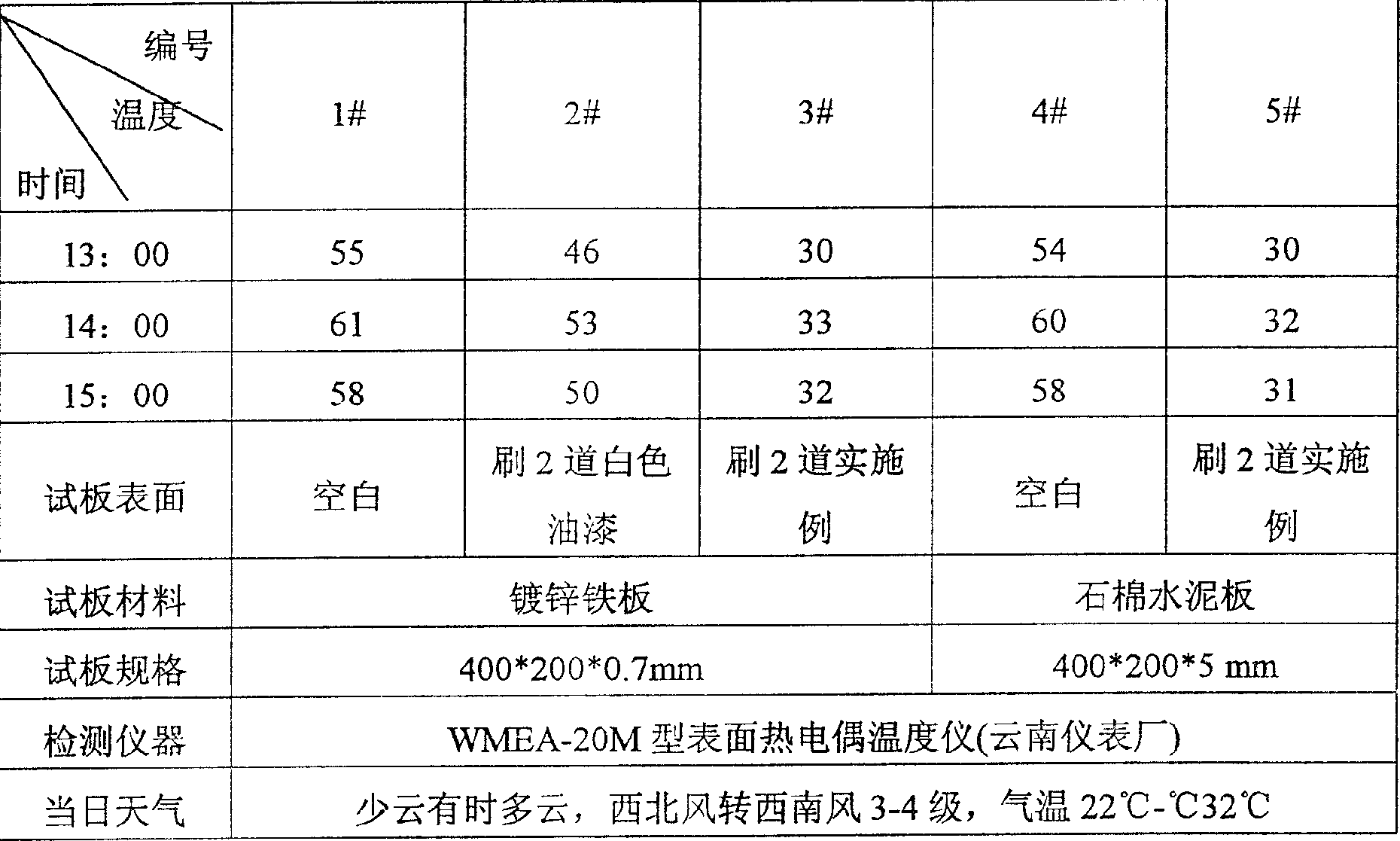

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com