Element feeding device and mounting machine therewith

A technology for component supply and electronic component installation, applied in the direction of electrical components, electrical components, etc., can solve the problems of inability to stably supply electronic components to the main body of the installation machine, inability to maintain the shuttle for electronic components, and inability to adsorb the bottom side well. Effect of stable supply of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

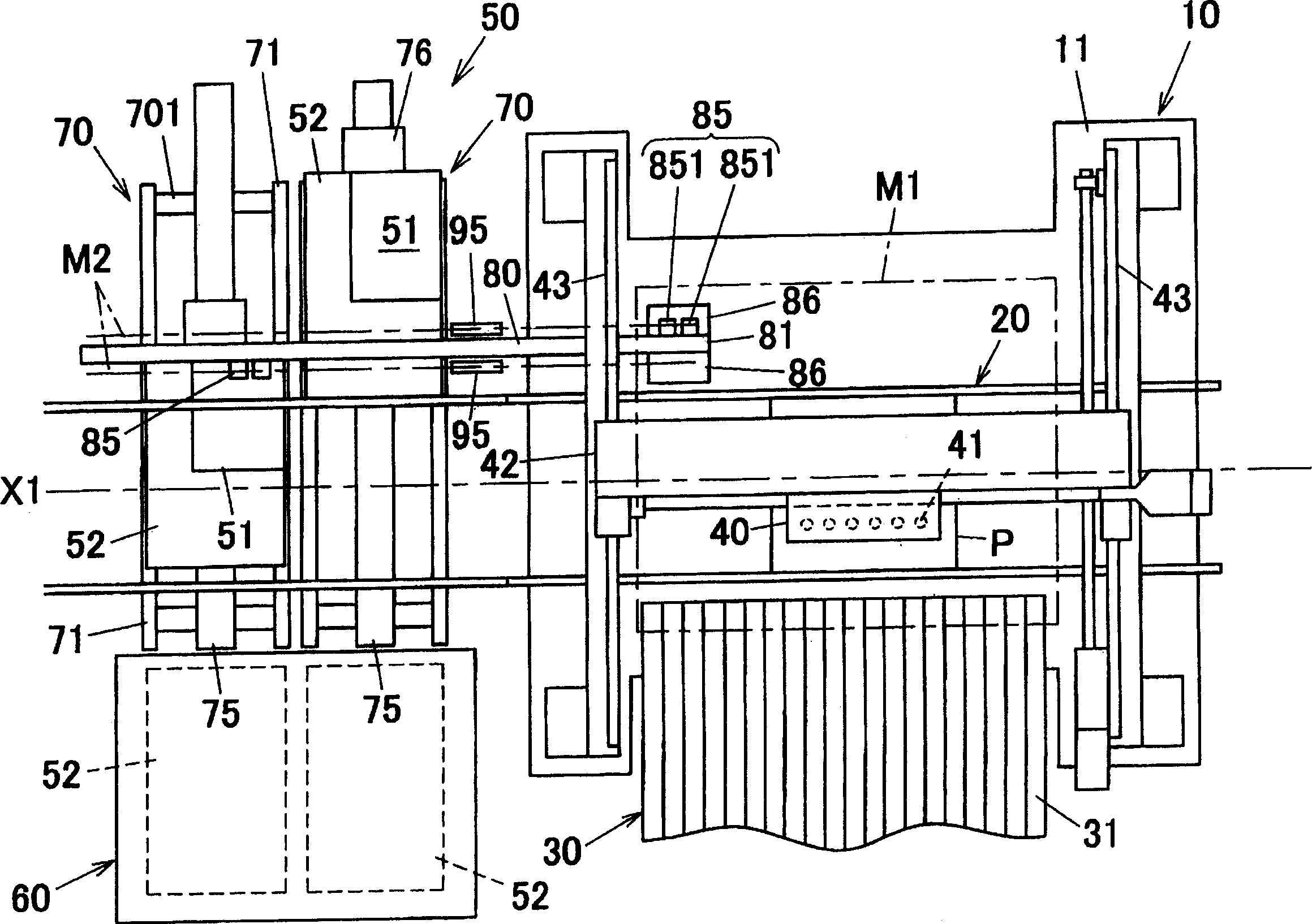

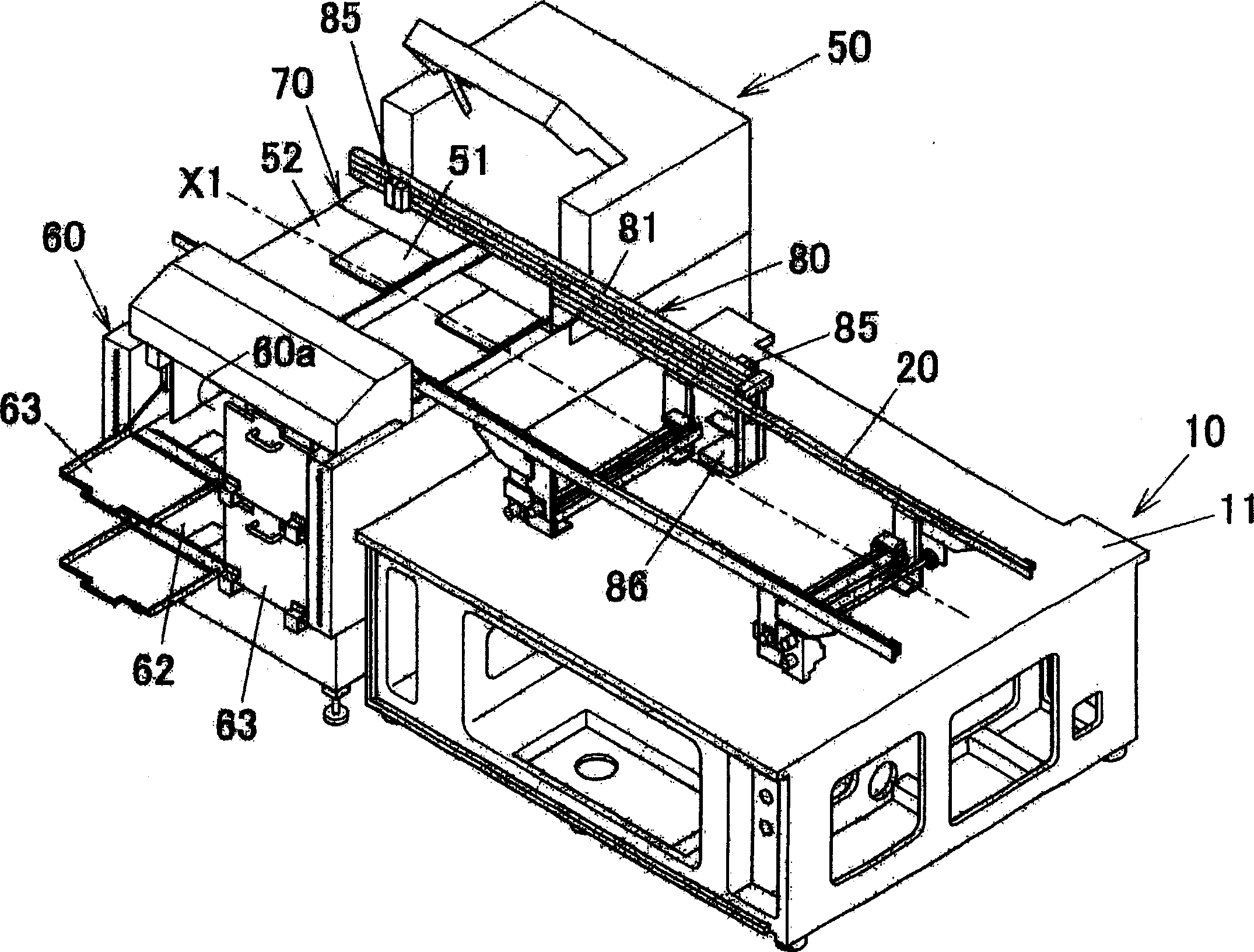

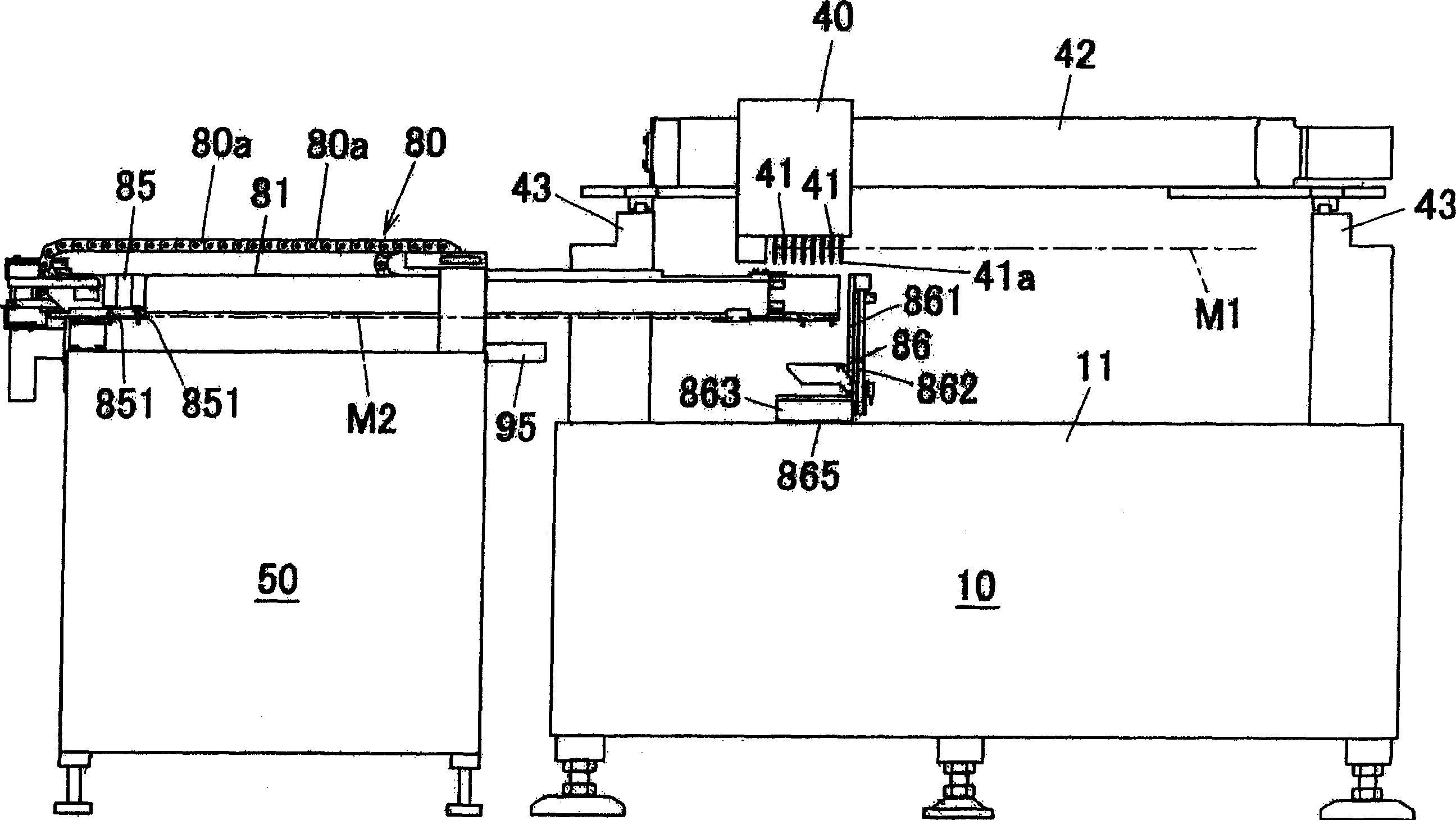

[0035] figure 1 It is a plan view of the embodiment of the mounting machine of the present invention. figure 2 is a perspective view schematically showing the mounting machine. image 3 is also a front sectional view briefly showing the mounting machine. As shown in these figures, the mounter has a mounter main body 10 and a component supply device 50 arranged side by side along a conveyance line X1 of a printed wiring board P to be mounted.

[0036] The mounting machine main body 10 is arranged along the conveying line X1 on the base 11, and has a conveyor belt 20 for conveying the printed circuit board P, a component supply unit 30 arranged on one (front side) of both sides of the conveyor belt 20, and a device. The head unit 40 for installation above the base 11 .

[0037] The component supply section 30 has a multi-row tape feeder 31 . . . suitable for supplying relatively small chip components.

[0038] Each tape feeder 31... is detachably installed with a reel, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com