Ink jet recording sheet

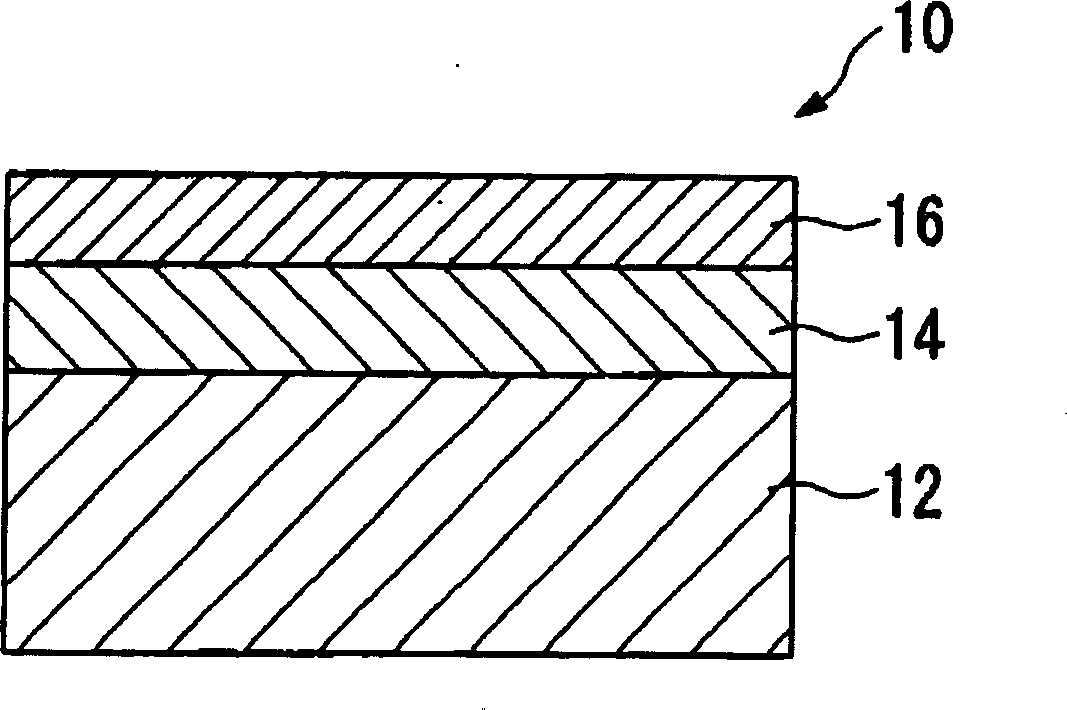

An inkjet recording and paper-using technology, which is applied in the direction of copying/marking, printing, etc., can solve the problems that the printed part is not well preserved, the pigment particles are large, and the printed image cannot be obtained, so as to achieve excellent preservation, Excellent color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] [Paper Base A]

[0137] Add 20 parts of light calcium carbonate to 100 parts of hardwood bleached kraft pulp (water drainage is 400ml CSF), add 1 part of cationic starch, 0.2 part of anhydrous alkenyl succinic acid neutral filler, fully mix to Form the raw material for papermaking, dry to a moisture content of 10% using a fourdrinier multi-drum paper machine, and apply 4g / m on both sides with a press 2 7% oxidized starch solution, dried to a moisture content of 7%, prepared to obtain a paper weight of 200g / m 2 The paper substrate A.

[0138] [Undercoat coating solution A]

[0139] 100 parts of titanium dioxide (manufactured by Sakai Chemical Co., trade name: R-21, secondary particle size. -376, emulsion type binder) and 5 parts of oxidized starch (manufactured by Oji Corporation, trade name: Ace A, water-soluble binder) are dispersed in water as a binder to obtain a base Coating solution A.

[0140] [Ink Receiving Layer Coating Solution A]

[0141] 100 parts of we...

Embodiment 2

[0145] [Paper base B]

[0146] Add 20 parts of light calcium carbonate to 70 parts of hardwood bleached kraft pulp (400ml CSF) and 30 parts of deinked newspaper old paper pulp (250ml CSF), add 1 part of cationic Starch, 0.2 parts of anhydrous alkenyl succinic acid neutral filler, fully mixed to form papermaking raw materials, dried to 10% moisture using a fourdrinier multi-drum paper machine, and coated with 4g / m on both sides by a press 2 7% oxidized starch solution, dried to a moisture content of 7%, prepared to obtain a paper weight of 200g / m 2 The paper substrate B.

[0147] [Manufacture of inkjet recording paper]

[0148] Inkjet recording paper was produced in the same manner as in Example 1, except that the paper base A in Example 1 was changed to the paper base B. In addition, the white paper portion on the surface of the ink-receiving layer of the obtained inkjet recording paper had a 60-degree specular gloss of 3% according to JIS-Z8741.

Embodiment 3

[0150] [Paper Base C]

[0151] 20 parts of light calcium carbonate are added to 70 parts of hardwood bleached kraft pulp (400ml CSF drainage) and 30 parts of deinked restained old paper (restained old paper: also used in color printed wood-free paper) Add 1 part of cationic starch and 0.2 part of anhydrous alkenyl succinic acid neutral filler to the mixed slurry of pulp (water drainage: 250ml CSF) containing fine art paper, and mix thoroughly to form papermaking raw materials, using Fourdrinier Dried to a moisture content of 10% in a multi-drum paper machine, and coated with 4g / m on both sides with a press machine 2 7% oxidized starch solution, dried to a moisture content of 7%, prepared to obtain a paper weight of 200g / m 2 The paper substrate C.

[0152] [Manufacture of inkjet recording paper]

[0153] Inkjet recording paper was produced in the same manner as in Example 1 except that the paper base A in Example 1 was changed to the paper base C. In addition, the white pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com