Improved club

A bat and hitting technology, applied in the direction of racket, sports accessories, etc., can solve the problems of inability to effectively absorb ground vibration, inability to absorb shock, and fragile structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

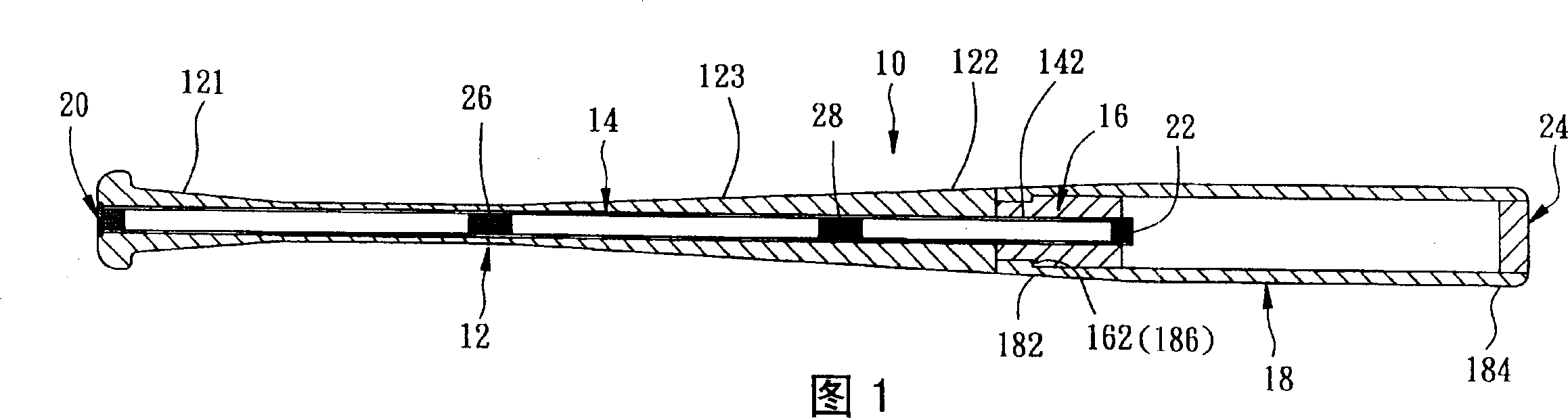

[0047] First, please refer to FIG. 1 , which shows a ball bat 10 according to a first preferred embodiment of the present invention, which has a grip portion 12 , a core tube 14 , an intermediate member 16 and a hitting portion 18 .

[0048] The handle 12 can be made of plastic, such as PU foam, or wood, and has a front end 121 , a rear end 122 and a body 123 whose outer diameter gradually increases from the rear end to the front end.

[0049] The core tube 14 is made of fiber-reinforced plastic, such as carbon fiber impregnated with epoxy resin, or metal, such as aluminum alloy, and is embedded in the axis of the grip portion 12 along the long axis of the bat. In other words, the length of the core tube 14 is longer than the handle portion 12, so that it has a bare section 142. In manufacturing, a shaft hole can be laid in the handle portion 12 and then the core tube 14 can be worn. Or place the core tube 14 in the center first and stick the handle portion 12 divided into sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com