Storage and transport device for flexible material and method of making same

a technology of flexible material and storage device, which is applied in the field of storage and transportation device of flexible material, can solve the problems of limited reel manufacturing, no simple solution for long distance shipping within most businesses, and companies that use reels typically do not assemble their own reels, and achieve the effect of quick and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

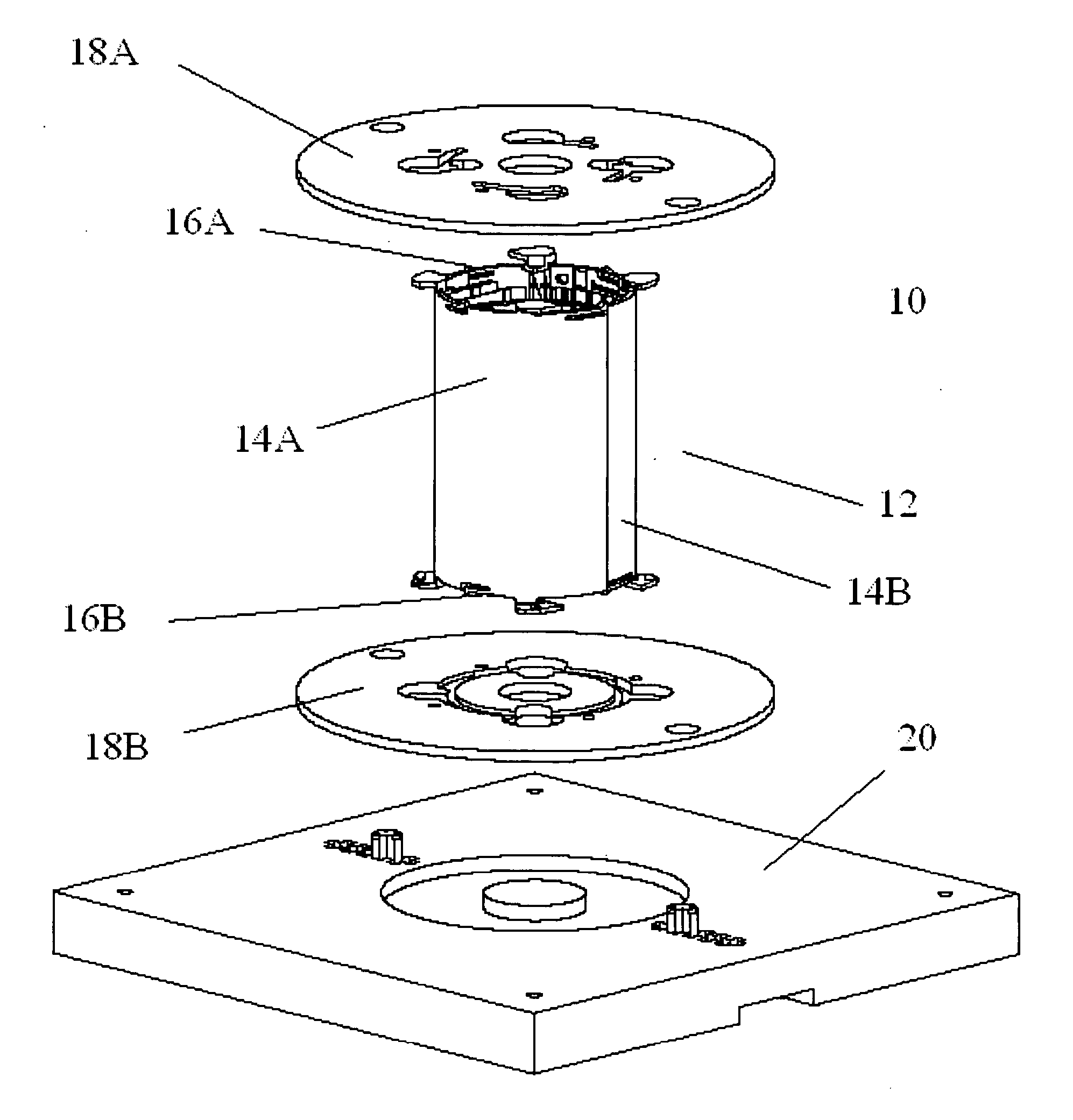

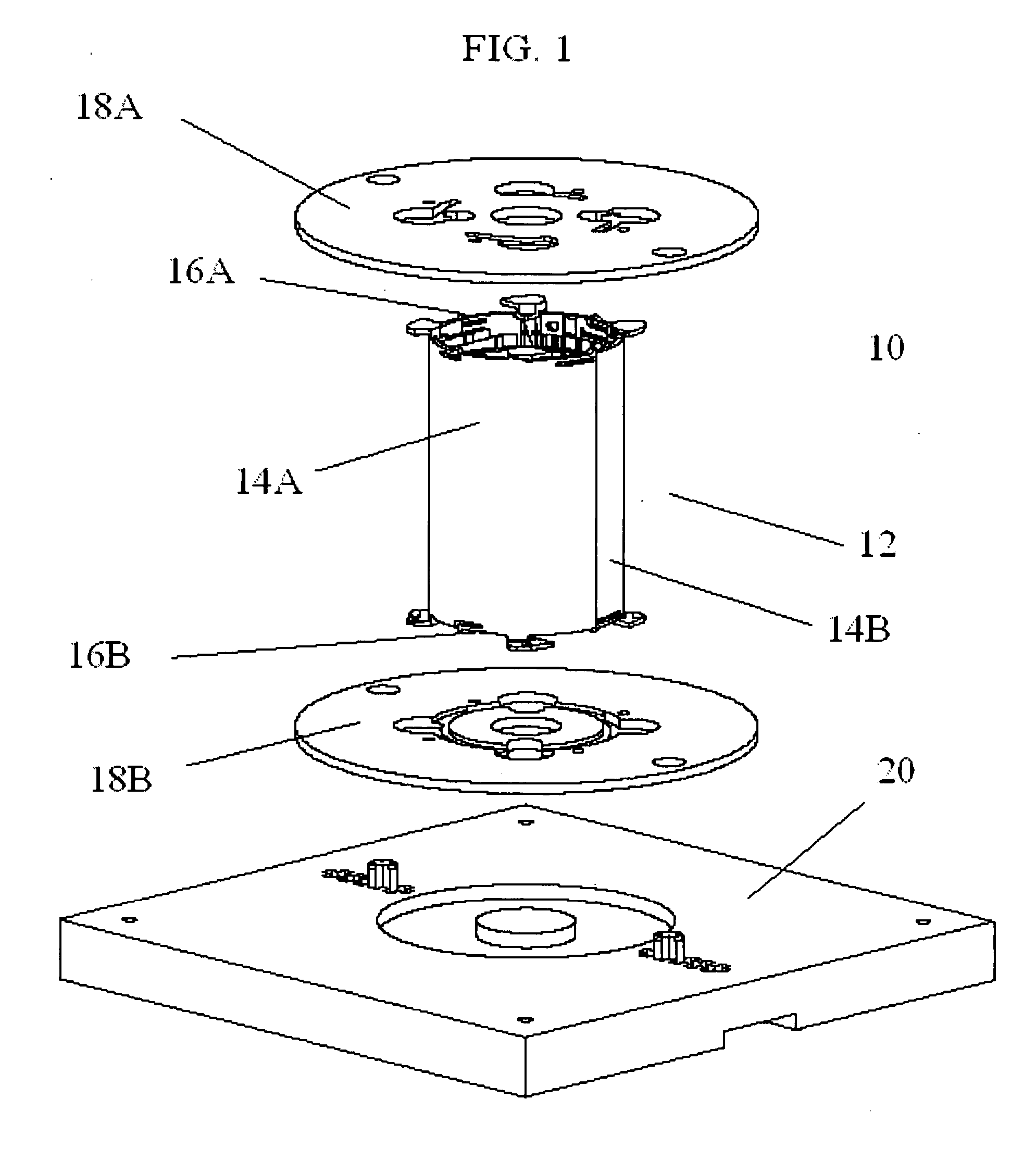

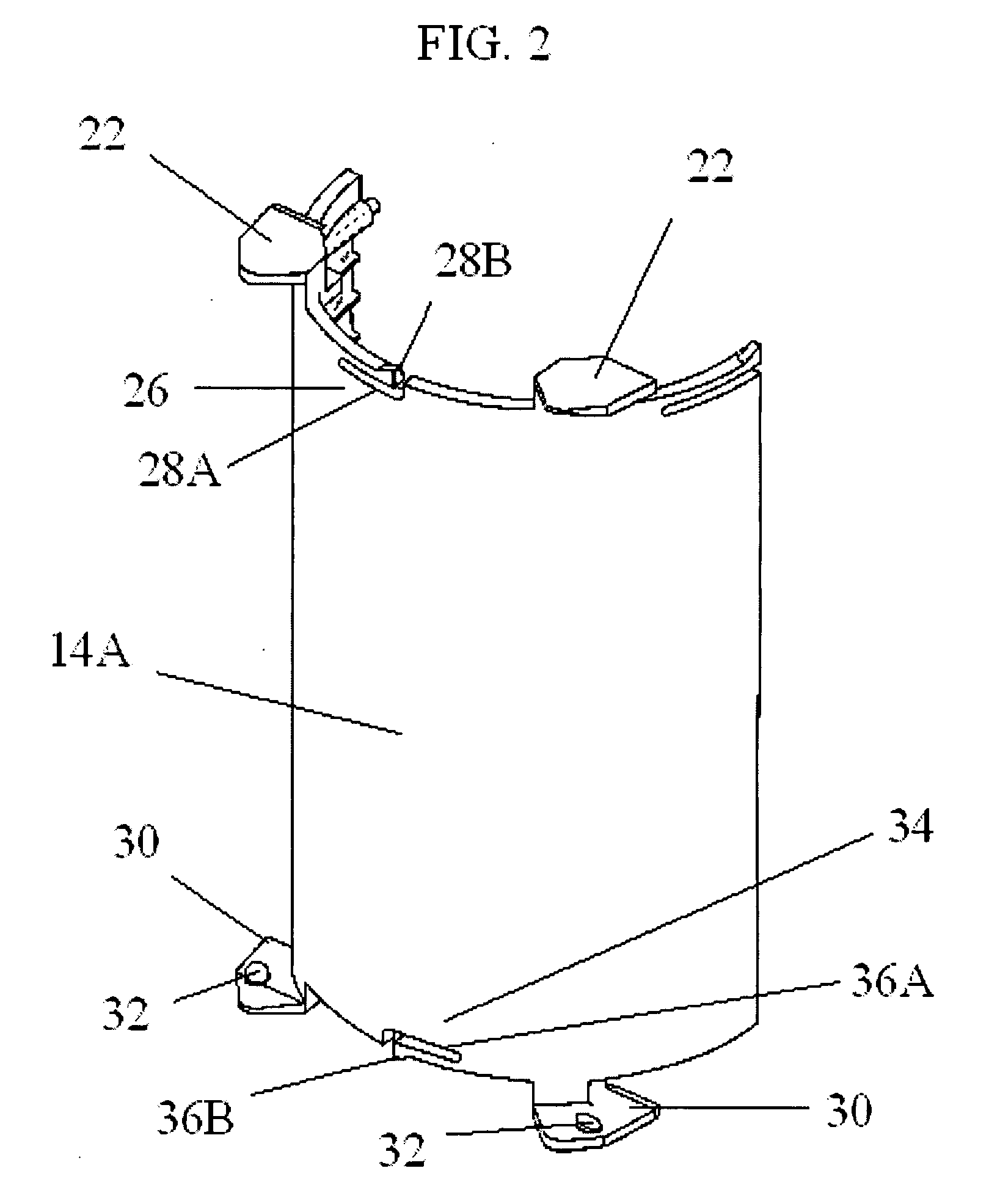

[0034]FIG. 1 illustrates a storage and transport device 10 for flexible material including, but not limited to rope, wire, cord, hose and cable. The device 10 includes a cylindrical core 12 having a first and second tube portion 14A and 14B (see FIG. 2 and FIG. 3A) that are held together by several locking mechanisms. It should be noted that first tube portion 14A and second tube portion 14B are identical and each includes the same components and locking mechanisms. Each tube portion 14A and 14B includes a top 16A and a bottom 16B. A first flange 18A is removeably attachable to the top portions 16A of the first and second tube portions 14A and 14B, and wherein a second flange 18B (see FIG. 3A) is removeably attachable to the bottom portions 16B of the first and second tube portions 14A and 14B. A base jig 20 is provided during assembly of the storage and transport device 10, holding the second flange 18B in position during rotation and locking of the cylindrical core 12 to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com