Production method of paper incense coil

A production method and technology of coiled incense, applied in the fields of botanical equipment and methods, biocides, plant growth regulators, etc., can solve the problems of high labor intensity, trouble, low work efficiency, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

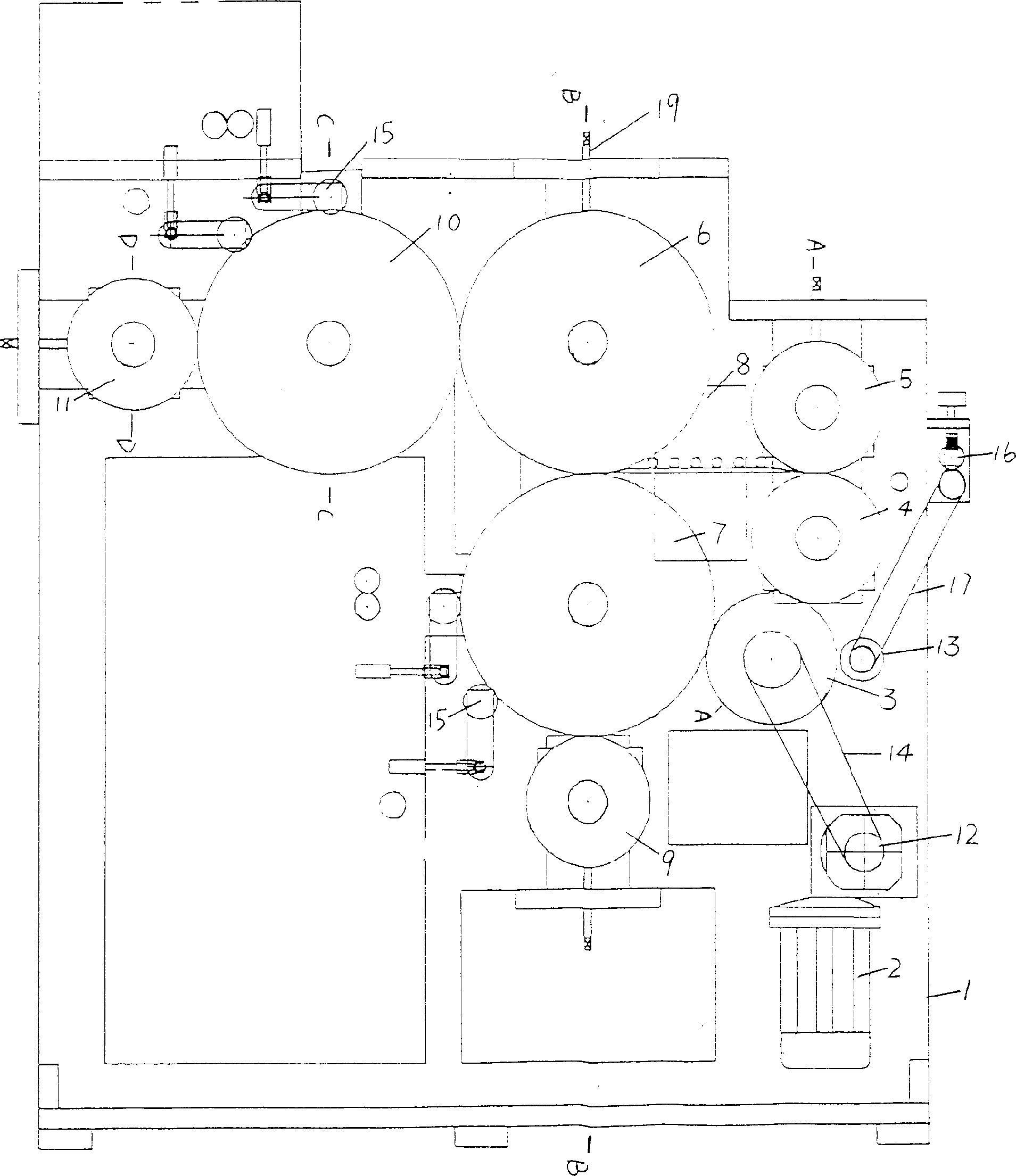

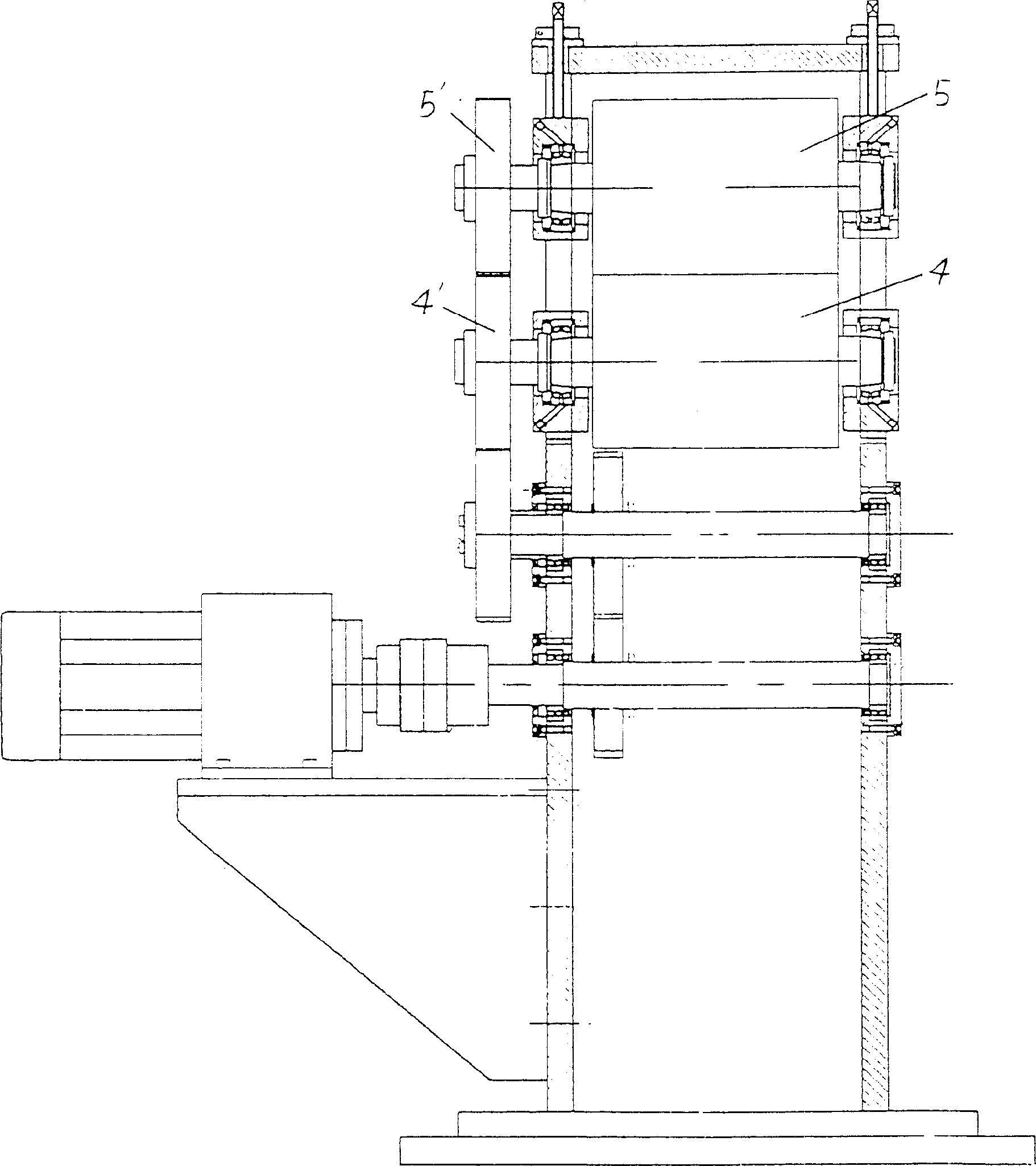

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

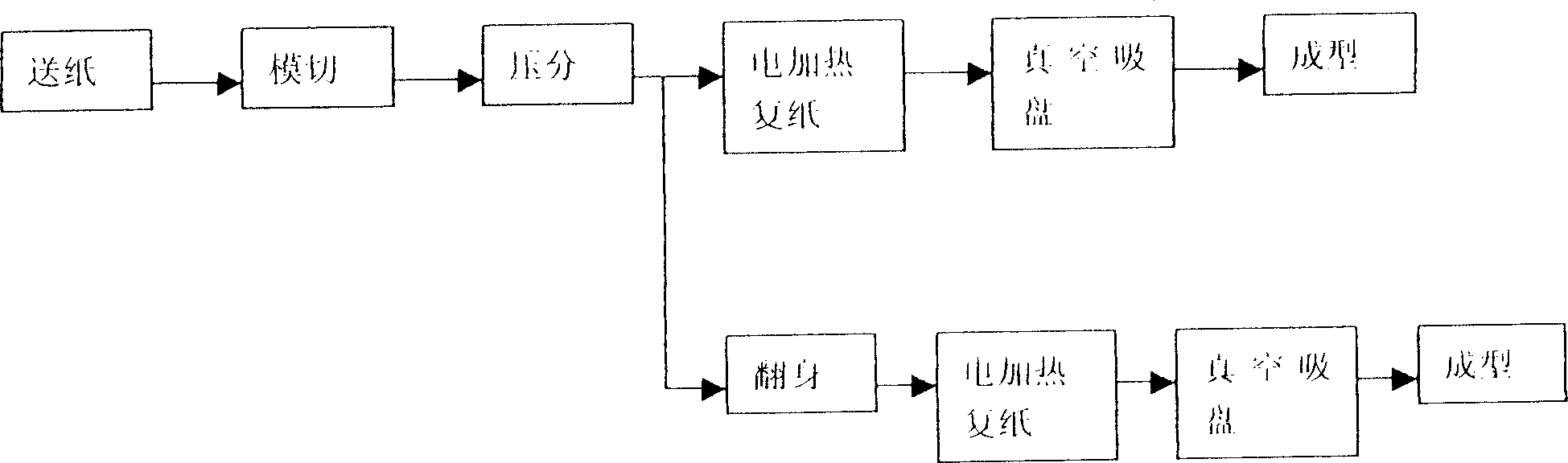

[0013] The present invention is a production method of paper coiled incense, characterized in that: the production method of said coiled incense comprises the following steps, a, sending the paper for producing coiled incense to the die-cutting machine in the frame through the paper feeding roller on the side of the frame Roller; b. Use the cutting knife of the die-cutting roller in the frame to die-cut the paper produced between the two die-cutting rollers to form a paper tray and use a cardboard to send the paper tray to the upper and lower pressing rollers; c. The paper tray entering the upper and lower pressing rollers is divided into two routes, one route is sent to the turning roller by the upper pressing roller; d, the turning roller turns the paper tray over, and passes through the electric heating roller at the edge of the turning roller Carry out electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com