Rotation device for vacuum vertical planet clamp

A rotating device and planetary technology, which is applied in the field of vacuum coating door body vertical planetary fixture rotation device, can solve the problems of short life, low vacuum degree, pollution, etc., and achieve the effect of improving service life and vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

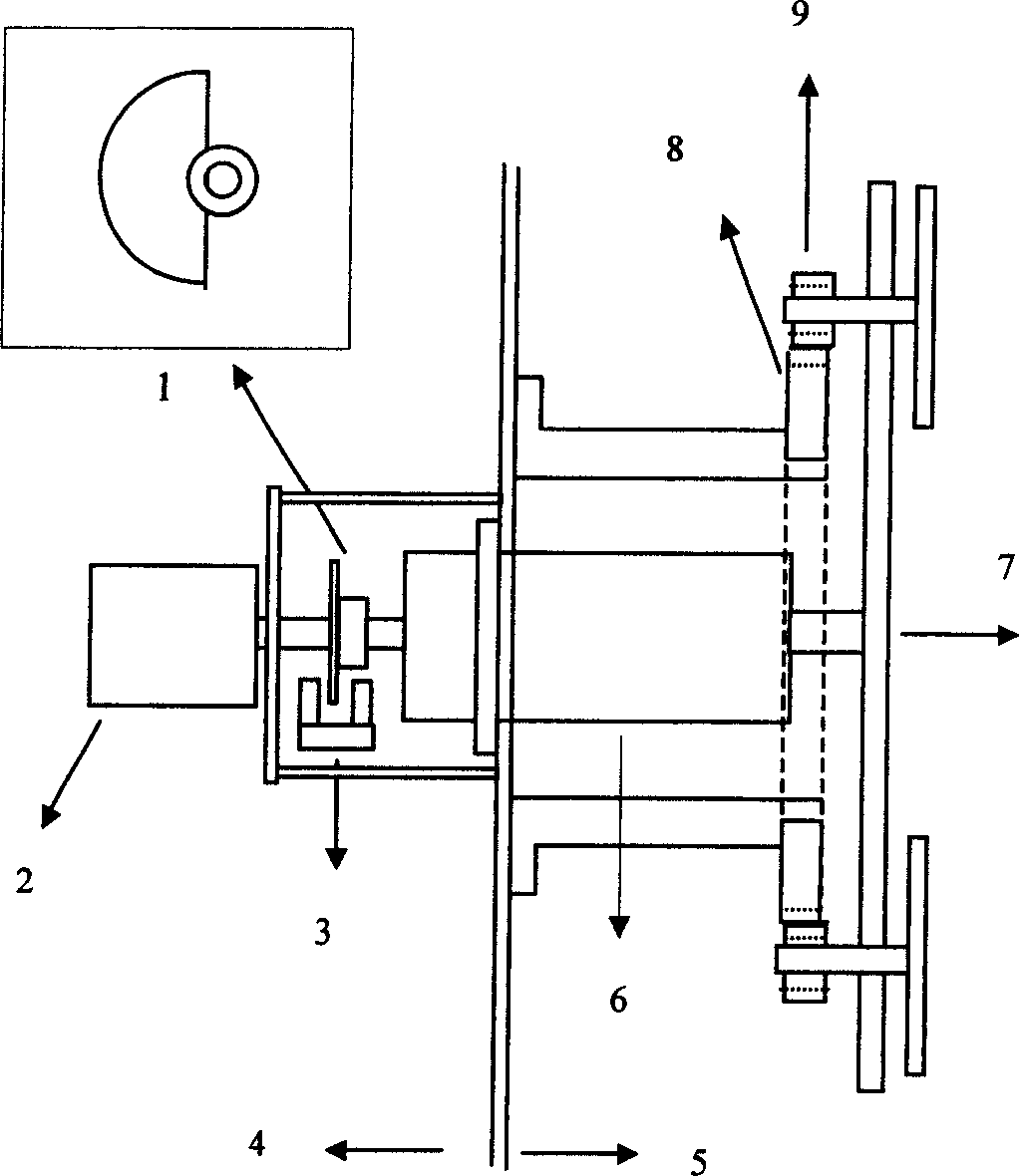

[0009] like figure 1 , figure 2 As shown, the present invention is composed of a speed-regulating motor 2, a vacuum chamber 5, a magnetic fluid 6, a planetary fixture 7, an active fixed gear 8, and a driven pinion 9. The motor 2 is connected to the main shaft of the magnetic fluid 6, and drives the planetary fixture 7 connected to the sealed main shaft 10 to rotate. The driven pinion 9 on the planetary fixture 7 revolves around the driving gear 8 fixed on the support frame while maintaining rotation. Keep each part with good coaxiality to prevent the rotation from getting stuck. The rotation state of the planetary clamp 7 can be monitored through the photoelectric switch 3 and the chopper 1 installed on the sealing main shaft 10 .

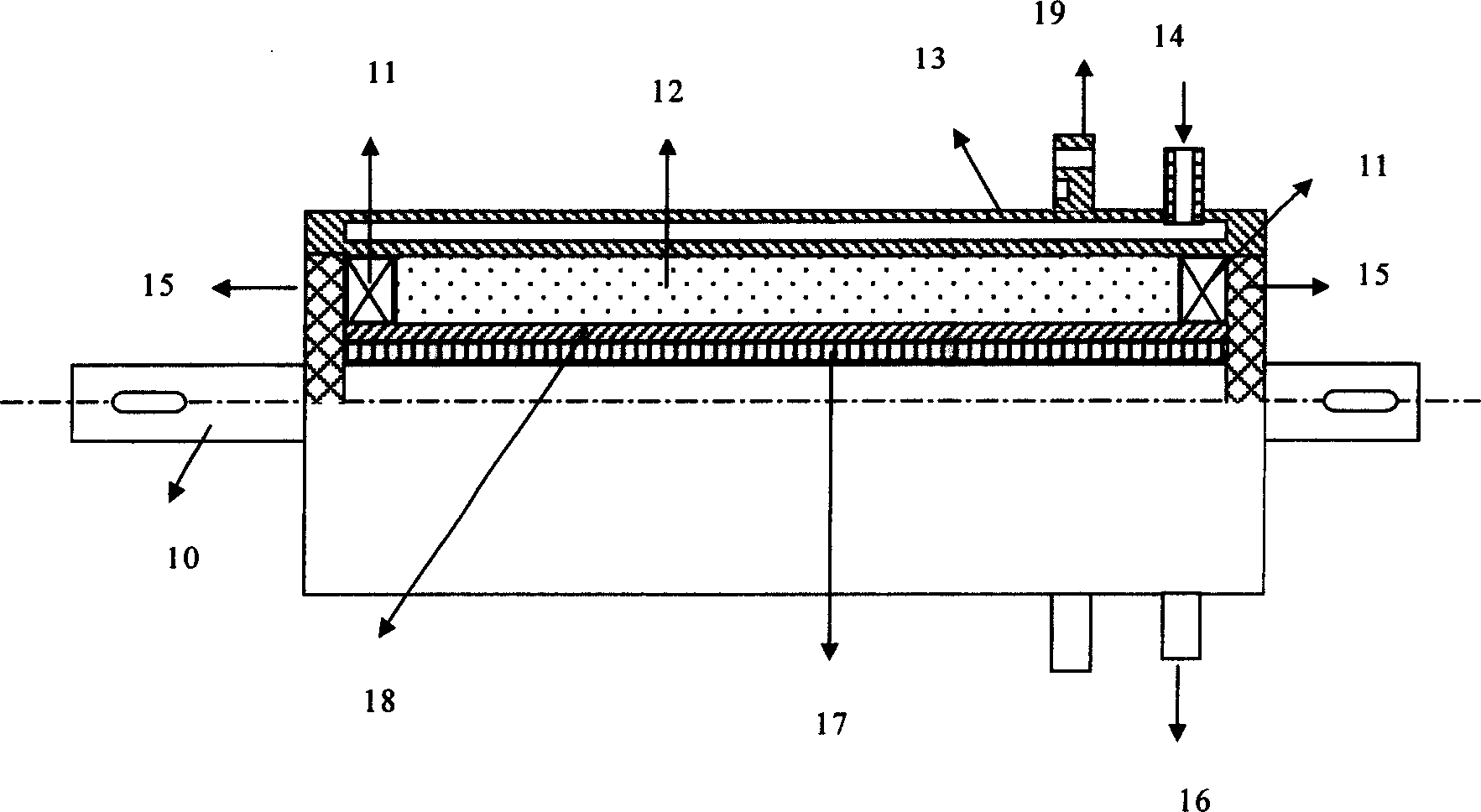

[0010] Magnetic fluid 6 mainly includes: sealed main shaft 10, load-bearing and positioning bearing 11, magnetic fluid 12, magnetic fluid housing 13, water inlet joint 14, screw cap 15, water outlet joint 16, heat insulation sleeve 17, magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com