Shaping ironing machine

An ironing machine and ironing technology, which is applied to washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of reducing machine ironing efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

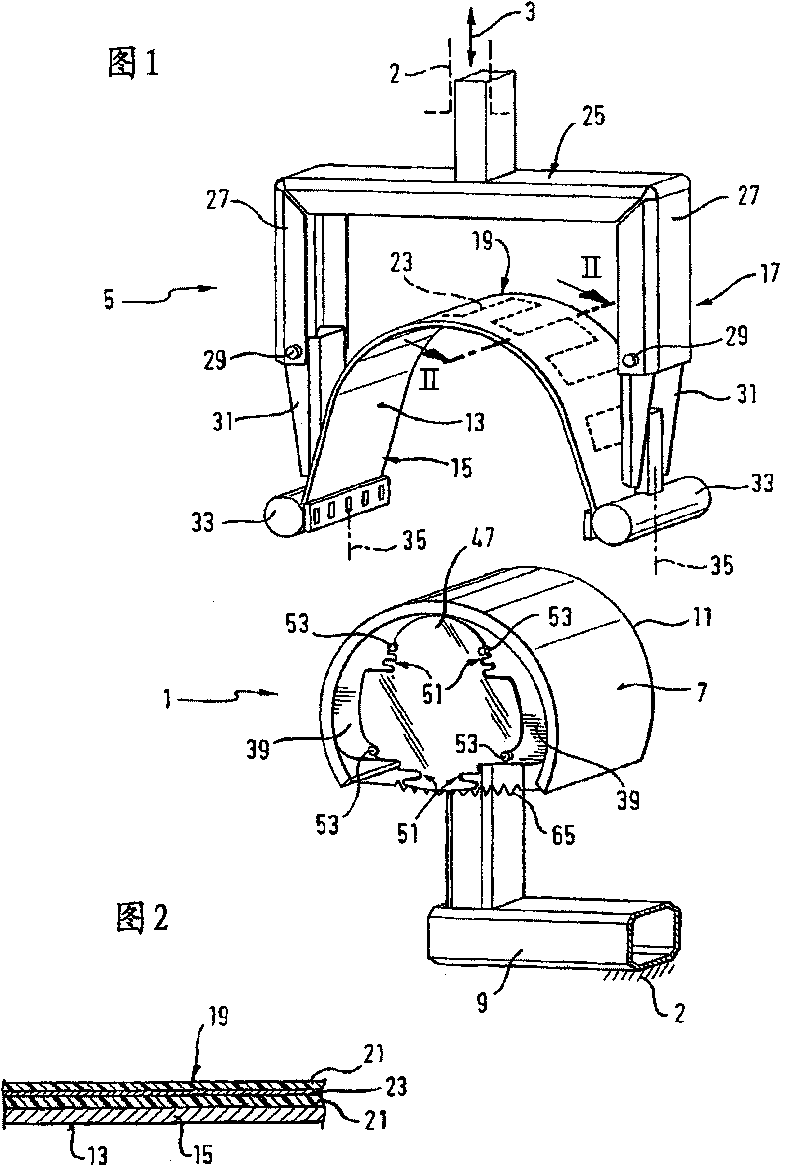

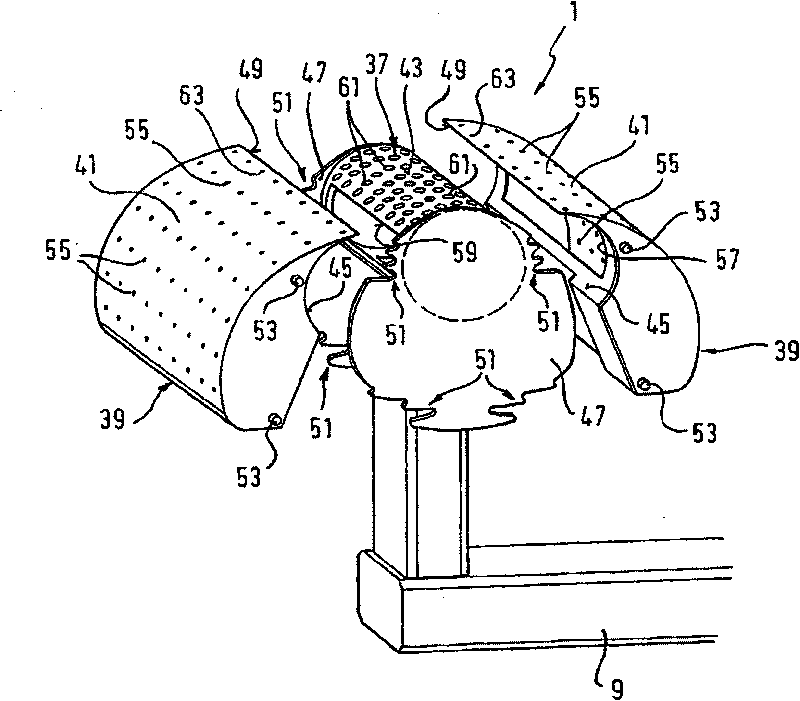

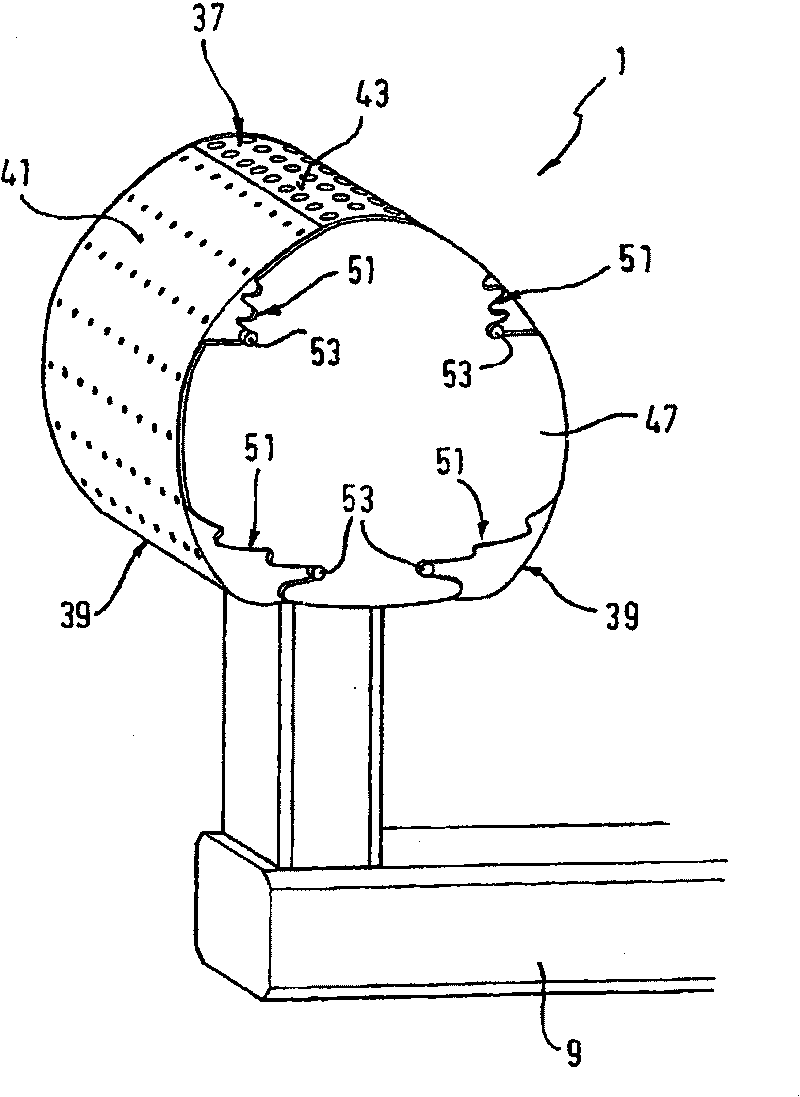

[0034] figure 1 Indicates an ironing die of an ironing machine for ironing cuffs or / and collars of shirts, shirts, etc. The ironing mold comprises a lower mold 1 fixedly mounted on a support represented by 2 and an on-machine machine that can leave the lower mold 1 and move towards the lower mold 1 in the direction of the double arrow 3 by a driving device not specifically drawn. The upper mold 5 that moves on the seat 2. The lower mold 1 has an ironing surface 7 following a cylindrical surface with a variable radius of curvature curve that will be described in detail later, on which the ironed object is processed according to its curvature, and upper mold 5 such as figure 1 Lift as shown in . Lower mold, as also will explain later, has many through holes on the peripheral wall of its determination ironing surface, they are connected on the suction pump that does not draw in detail by a pipe 9 that forms lower mold 1 support simultaneously. A strip-shaped, flexible and bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com