Rapid treatment process for middle-small sewage source, and integrated rapid sewage treatment station thereof

A technology of sewage treatment station and treatment process, which is applied in the direction of neutralized water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem that the treatment effect is difficult to meet the discharge requirements and the structure of sewage treatment pool Unreasonable, increasing the construction cost of sewage treatment stations, etc., to achieve the balance of sewage collection components, good sewage oxidation effect, and change the effect of harsh working environment and secondary pollution factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

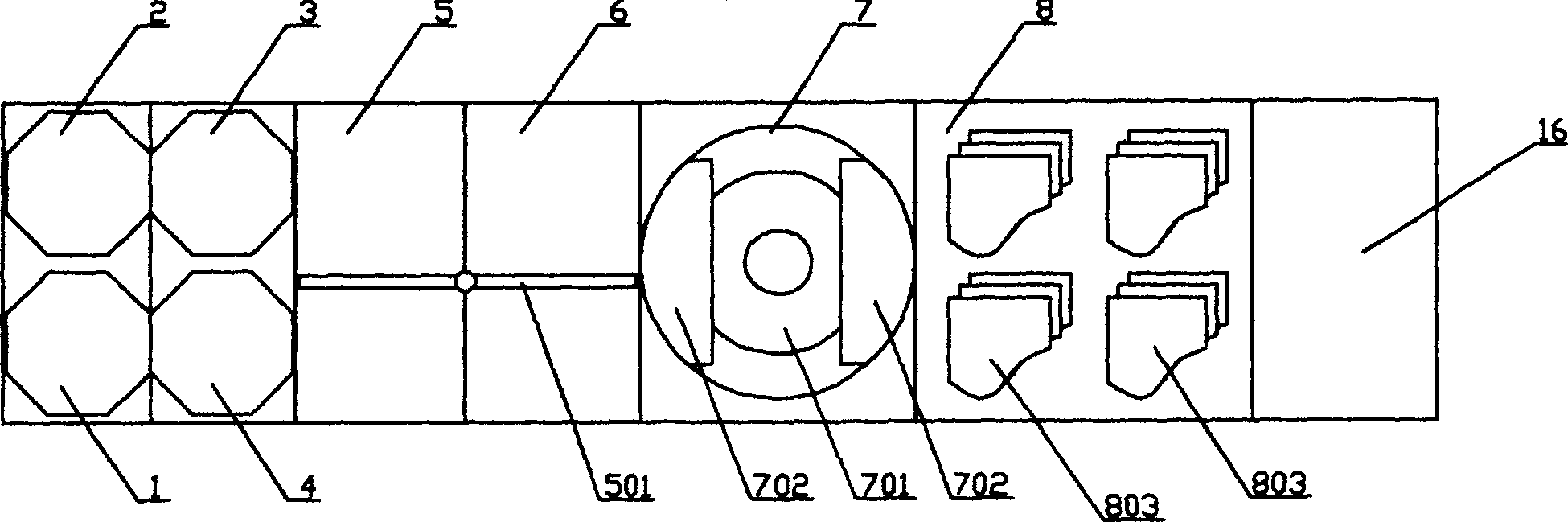

[0033] by figure 1 As shown, the rapid treatment process for small and medium-sized sewage sources, and its treatment process is:

[0034] a. Use grids of different densities in the grid pool to remove large floating objects in the sewage;

[0035] b. Let the above-mentioned sewage enter the balanced gas explosion tank, and at the same time inject air into the tank, so that the sewage will undergo a chemical reaction when there is sufficient oxygen in the tank;

[0036] c. Let the above-mentioned sewage enter the adjustment tank, and the automatic acid and alkali dosing device of the adjustment tank will adjust the PH value of the sewage entering the adjustment tank after receiving the signal from the equalizing explosion tank;

[0037] d. Let the above-mentioned sewage enter the reaction tank, and according to the online PH value monitoring signal, the reaction tank automatically modulates the dosage of PAC, that is, polyaluminum chloride;

[0038] e. Let the above-mentioned sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com