Polymer-based casing for sausages

A technology of polymer and polymer film, which is applied in the direction of sausage casing, sausage casing extrusion, biaxially stretched sausage casing, etc., and can solve the problems of too hard shirring strips and loose shirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a method of making polymeric sausage casings in which the film has suitable barrier properties for the particular type of sausage meat to be packaged. The present invention also provides polymeric film compositions suitable for use in sausage casings.

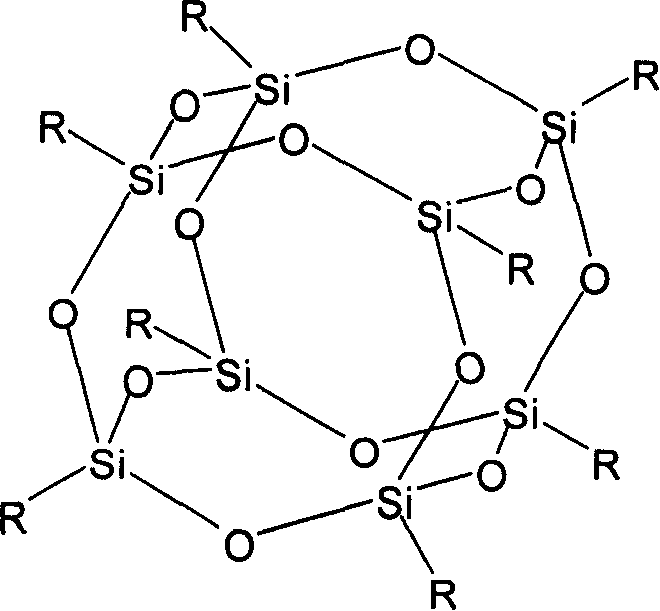

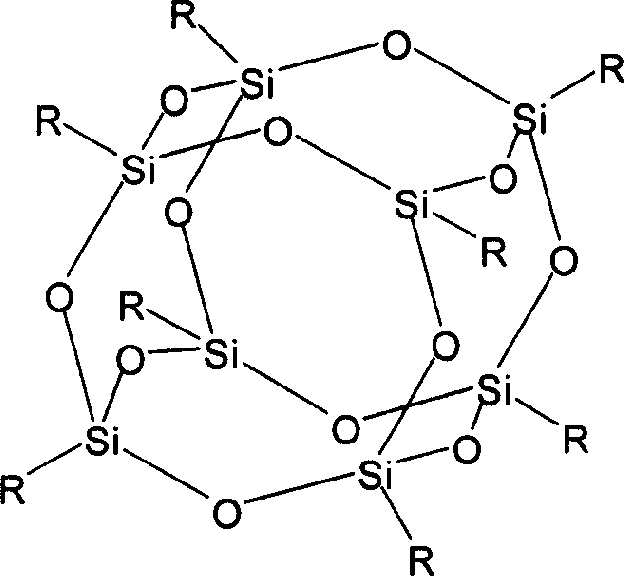

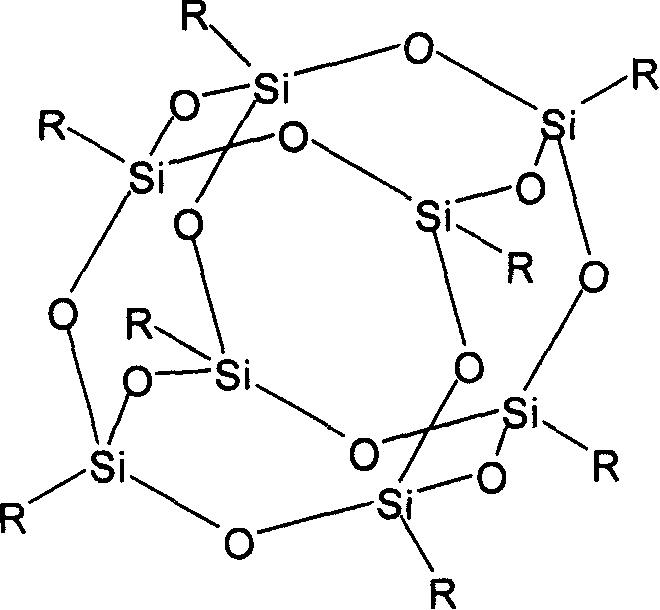

[0023] In a preferred embodiment, the polyamide resin and the silicon-based barrier control agent are mixed at a specific concentration of the silicon-based barrier control agent to form a master mixture. This master blend can then be blended or coextruded with neat polyamide, followed by biaxial stretch orientation, to produce a polyamide-based film. The type of silicon-based barrier control agent employed can be varied to provide films with increased or decreased barrier properties relative to pure polyamide. The amount of neat polyamide mixed or coextruded with the main mix can also be varied to control the permeability of the polyamide film. The polyamides used in the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com