Device for automatic measuring oil and gas

An automatic metering, oil and gas technology, applied in the direction of measuring device, volume flow measuring device, liquid/fluid solid measurement, etc., can solve the problems of poor operation safety, large space occupation, and many metering links, and achieve good reliability and pressure loss Small, high-precision measurement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

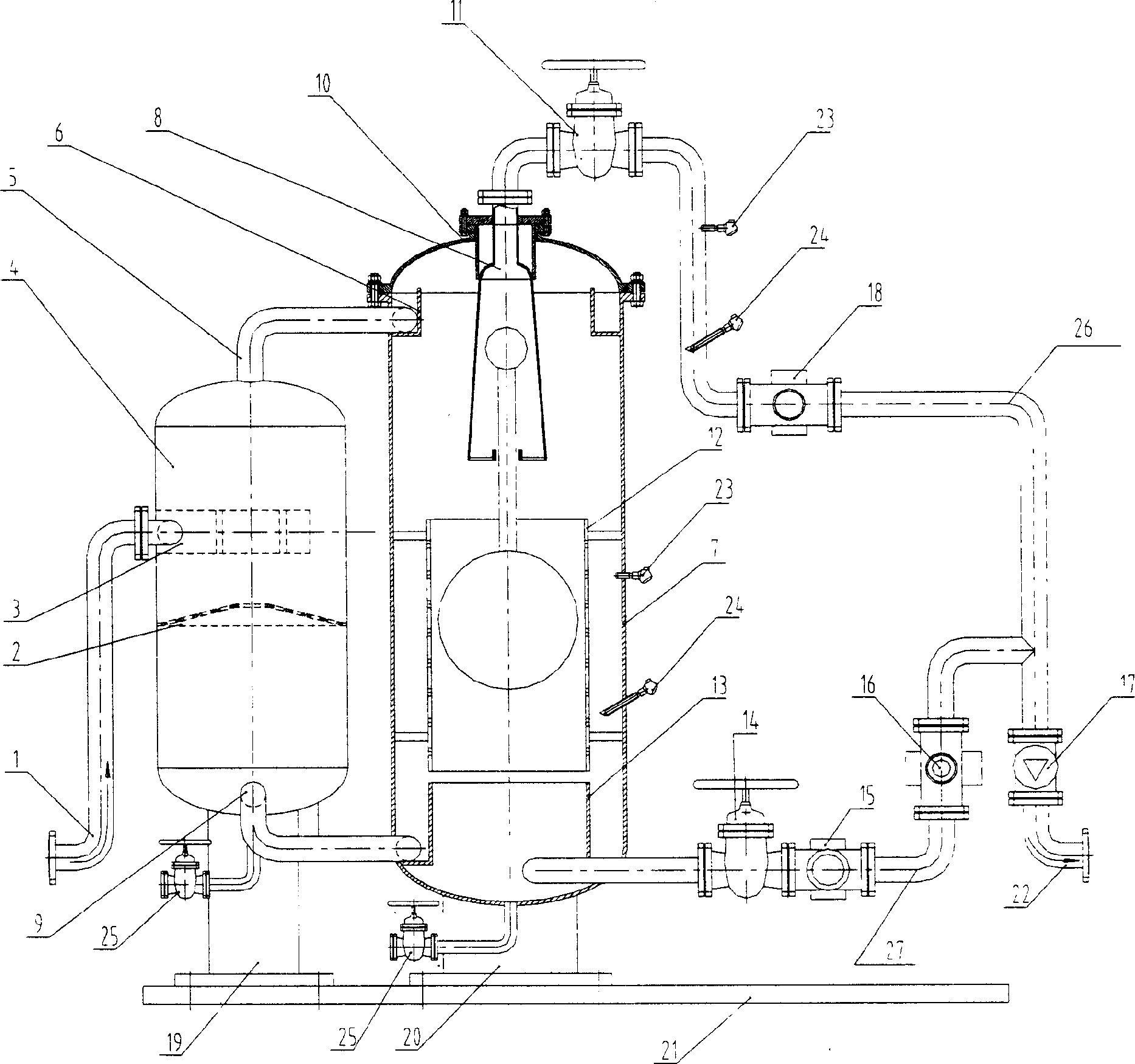

[0045] refer to figure 1 , the oil-gas mixture enters the oil-gas separation tank 4 from the oil-gas inlet pipe 1 (tangentially), and the gas-liquid preliminary separation is realized through the centrifugal separator 3, and the gas-containing liquid separated by the separator 3 falls to the ground under the action of gravity (and centrifugal force). On the gas-liquid separation sieve 2, through the sub-sieving of the gas-liquid separation sieve, the free gas in the oil-gas mixture from the pipeline can be completely separated.

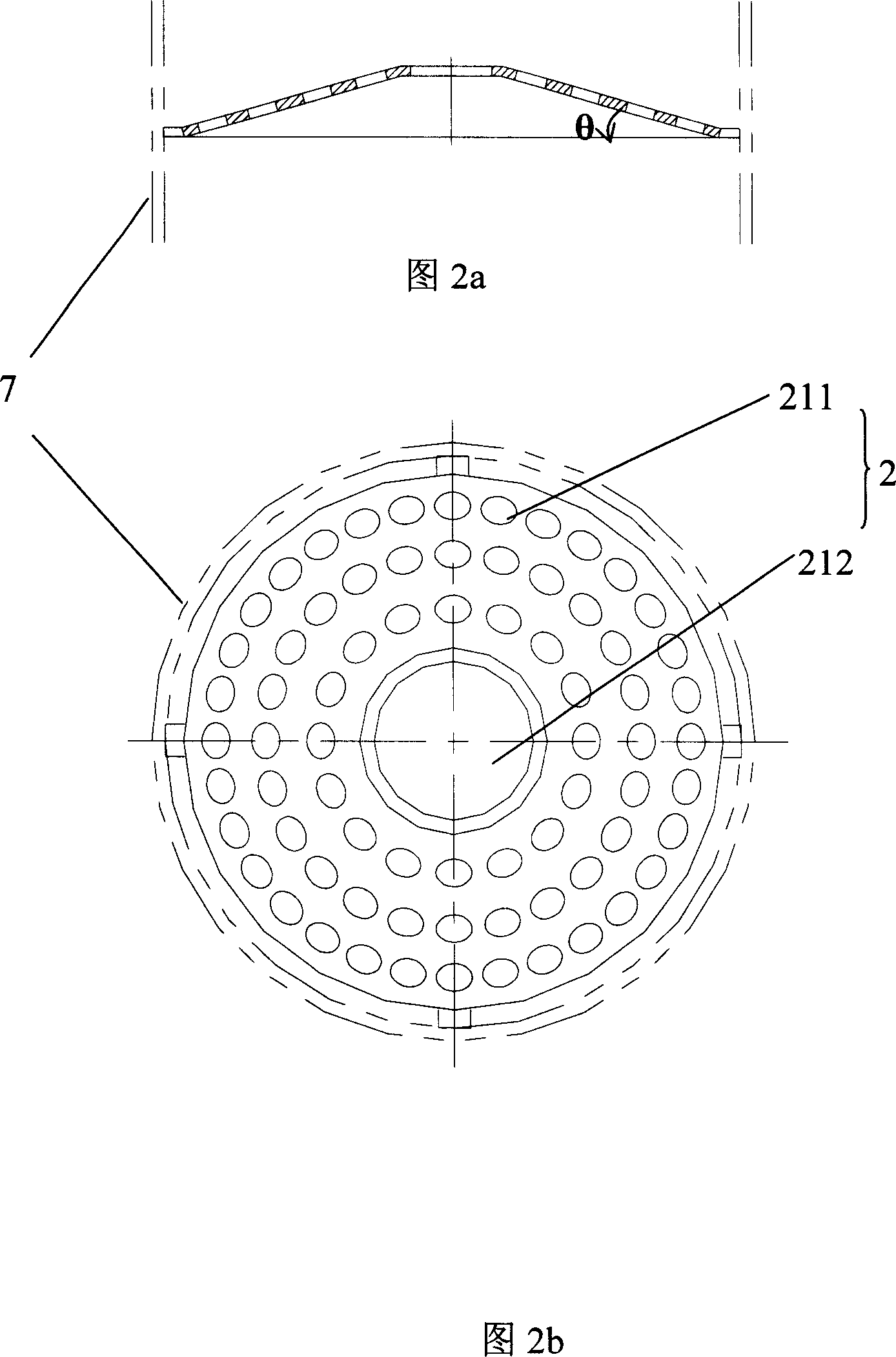

[0046] Referring to Fig. 2a and Fig. 2b, the gas-liquid separation screen 2 is an equilateral triangle structure (trumpet), placed horizontally in the middle and upper part of the oil-gas separation tank 4, with the convex surface upward, and the angle θ formed between the convex surface and the section (horizontal plane) of the separation tank 4 Less than 90 °, the convex surface is covered with mesh holes 211, so as to increase the liquid-gas separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com