Technique for preparing malonyl ginsenoside, and application of medication in treating diabetes

A technology of malonyl ginsenosides and ginsenosides, which can be used in drug combinations, medical preparations containing active ingredients, metabolic diseases, etc., and can solve problems such as the loss of water-soluble saponins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

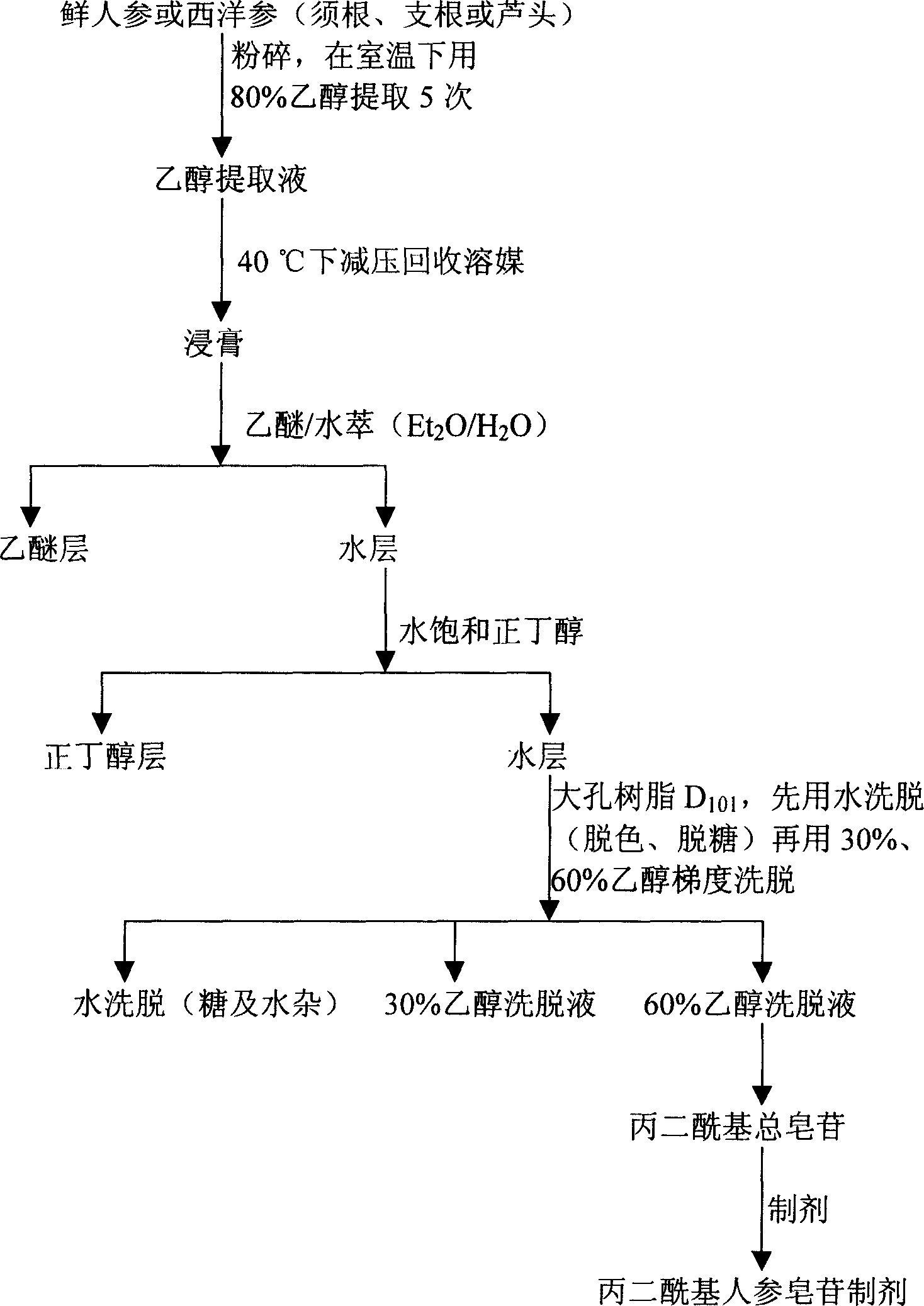

Method used

Image

Examples

Embodiment 1

[0116] Take 1kg of fresh ginseng (fibrous roots, branch roots, rhizomes, main roots, etc.) as raw material, chop it up, and use 15kg of 80% ethanol to extract it by cold soaking at room temperature for 3 times, each time for 8-16 hours. The extraction process should be fully stirred. The extract was recovered solvent under reduced pressure at 40°C, concentrated into an aqueous solution, extracted repeatedly with n-butanol: water, the aqueous layer solution was concentrated, then applied to a macroporous resin column, and eluted with water, 30%, 60% ethanol to obtain 60 The % ethanol part is total malonyl saponins, and the aqueous solution obtained by recovering ethanol is lyophilized and stored for later use, and then the preparation is developed. The shorter the experimental process of each step, the better, and the obtained samples should be stored at low temperature.

Embodiment 2

[0118] Take American ginseng (fibrous roots, branch roots, rhizomes, main roots, etc.) The solvent was recovered under reduced pressure, concentrated into an aqueous solution, extracted repeatedly with n-butanol: water, and the aqueous layer solution was lyophilized and stored at low temperature for future use. Take out the lyophilized sample and put it on the macroporous resin column, elute with water, 30% and 60% ethanol, and obtain 60% ethanol part as total malonyl saponins, and freeze-dry the aqueous solution obtained by recovering ethanol, and then develop the preparation. The shorter the experimental process of each step, the better, and the obtained samples should be stored at low temperature.

Embodiment 3

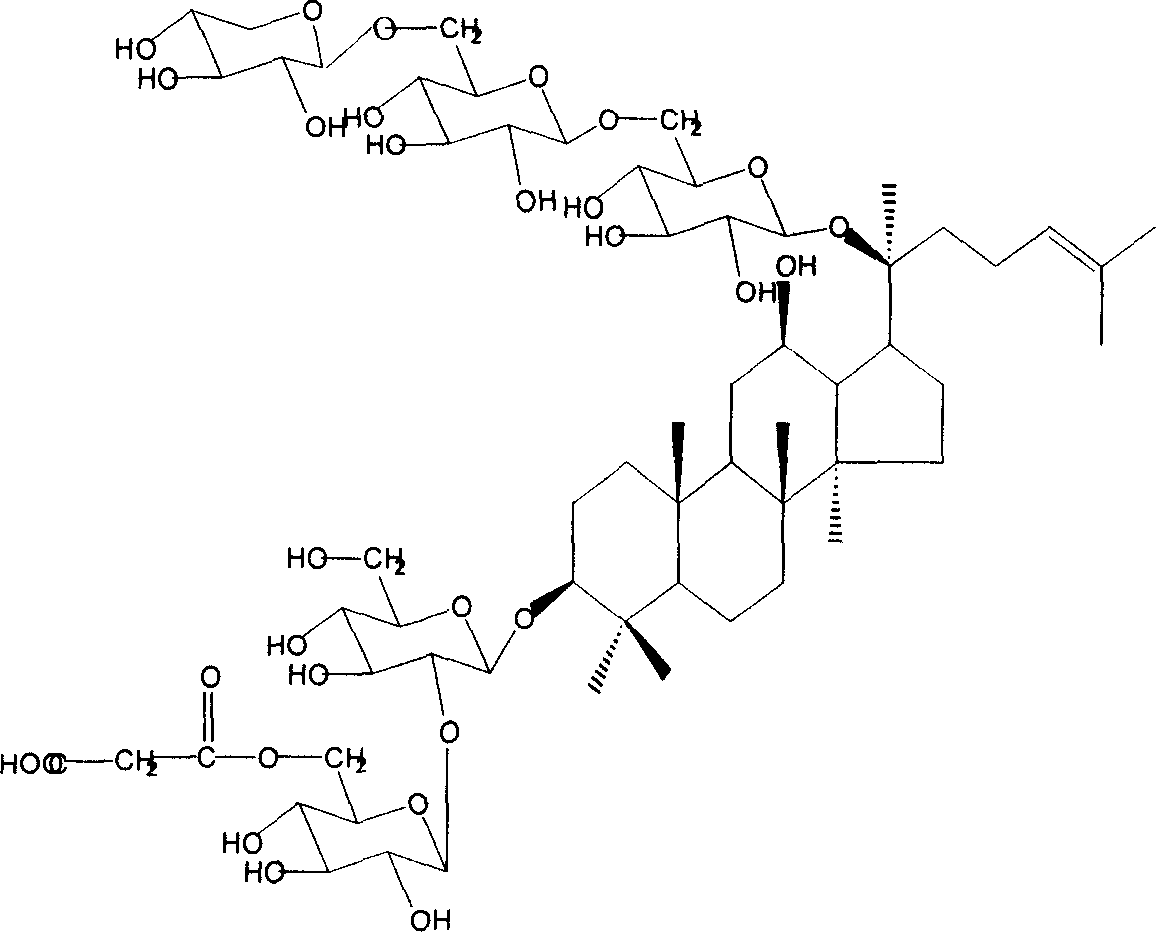

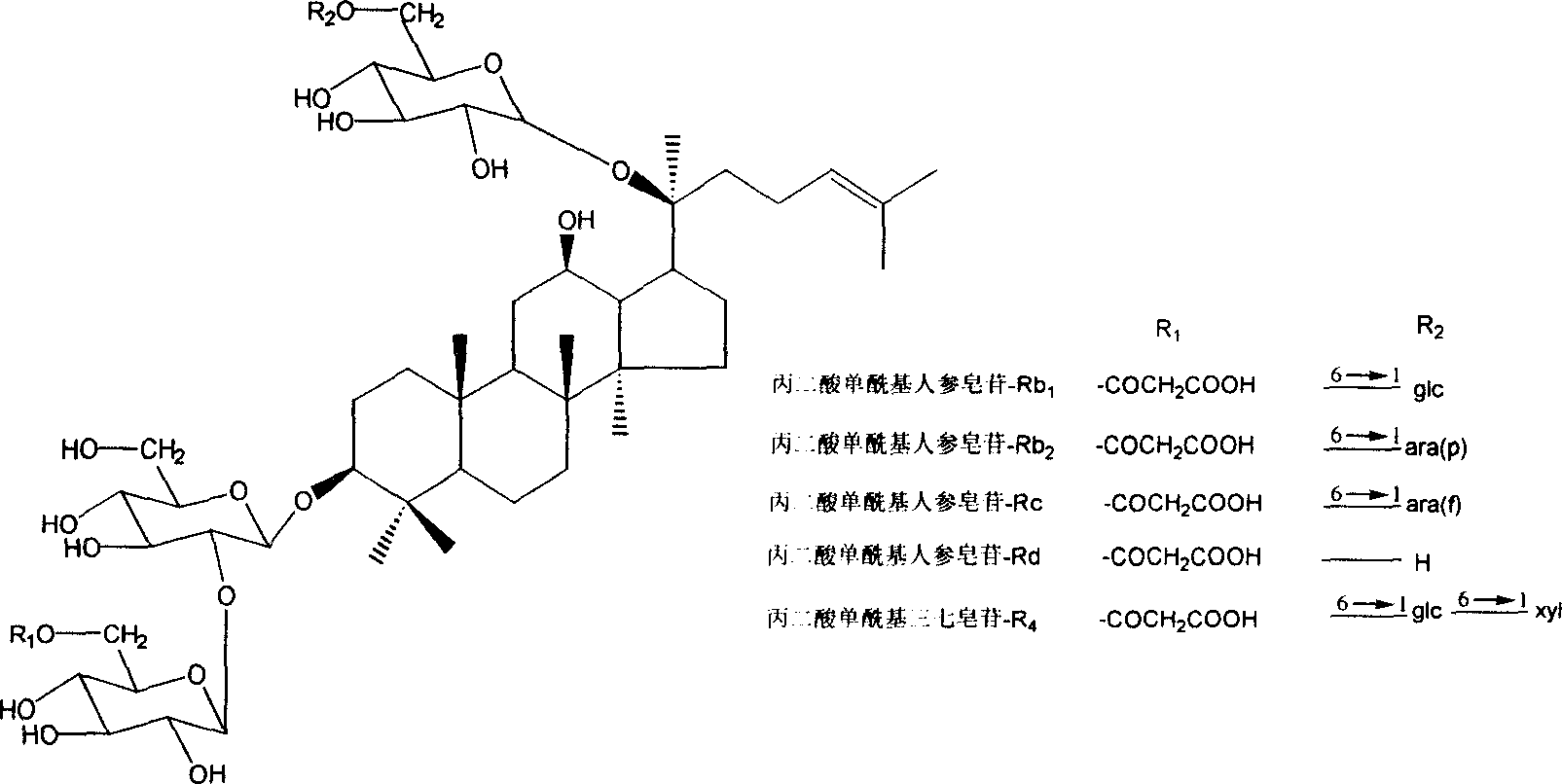

[0120] Get 60% ethanol phase (malonyl total saponins) 10g prepared in embodiment 1 or 2, dry loading, separate under reduced pressure with silica gel dry column (silica gel G 2Kg Qingdao ocean chemical factory production), use eluent (CHCl 3 -MeOH-H 2 O 65:35:10 lower layer) was washed to the bottom of the column, then cut off, checked with a thin layer of silica gel, and combined the components containing M-NR4.

[0121] Put the M-NR4 component on a silica gel dry column (600g, 300-400 mesh, 4.5×60cm), elute with chloroform-methanol-water (6:4:1), and check it with a thin layer of silica gel after breaking and cutting. H on M-NR4 + Type cation exchange resin column, continue to elute with ethanol, the eluate is concentrated under reduced pressure at 40°C, and the concentrated solution is recrystallized repeatedly with ethanol to obtain the compound malonyl notoginsenoside-R4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com