Flow control device for filling liquid

A technology of flow control device and filling volume, applied in the direction of using electric device flow control, valve device, liquid material, etc., can solve the problems of low product qualification rate, low measurement accuracy, and inaccurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

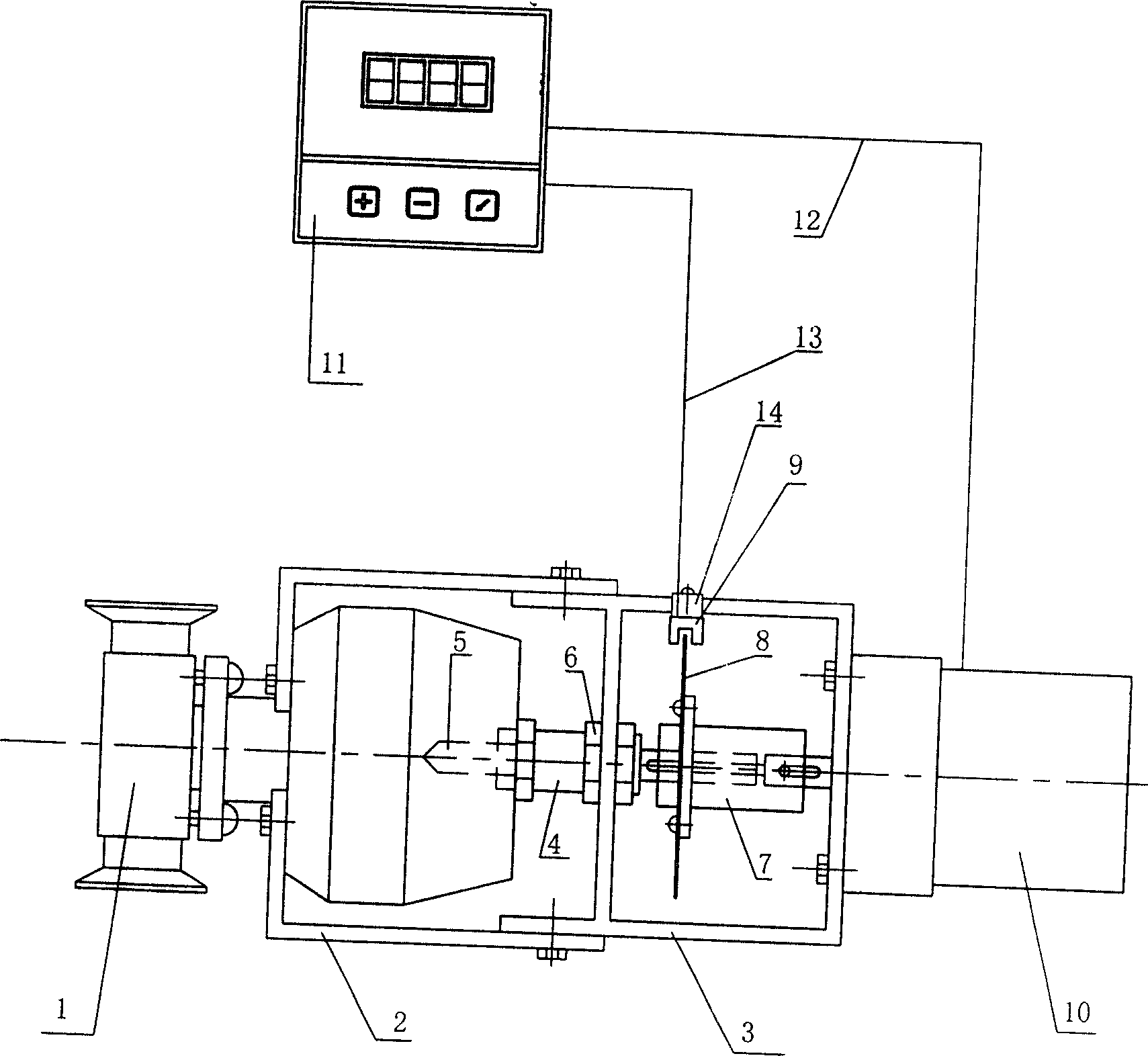

[0008] The present invention is described in detail below in conjunction with the embodiments given by the accompanying drawings.

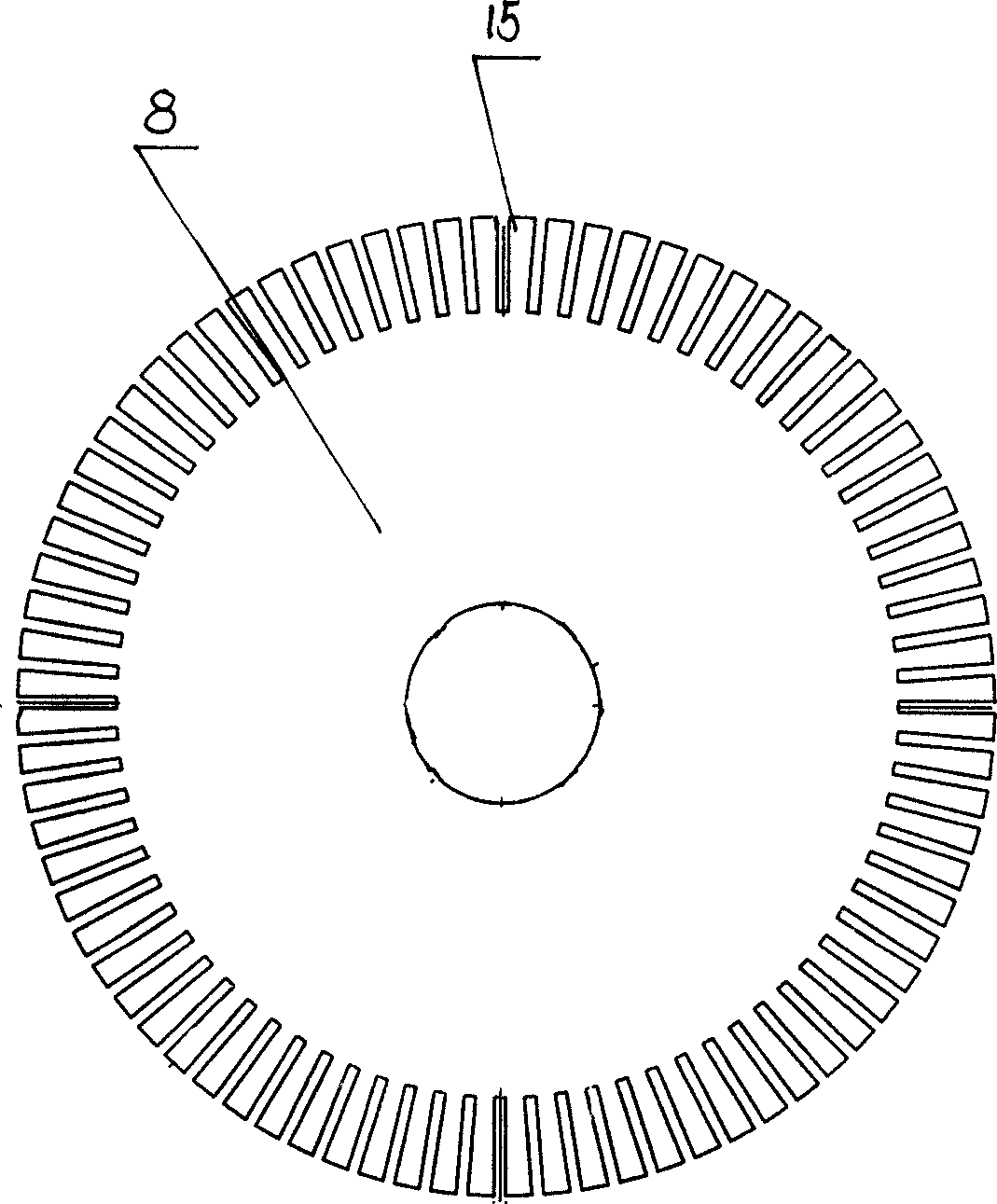

[0009] The liquid filling flow control device described in this embodiment consists of a pneumatic diaphragm valve 1, a valve body connecting frame 2, an adjusting motor frame 3, an adjusting screw sleeve 4, an adjusting screw rod 5, a lock nut 6, a connecting sleeve 7, and an adjusting disc 8 , trough-shaped detection switch 9, regulating motor 10, filling volume control box 11, motor control line 12, detection signal line 13, trough-shaped switch frame 14 and control software (such as figure 1 shown). The pneumatic diaphragm valve 1 and the regulating motor 10 are connected as a whole through the integral frame composed of the valve body connecting frame 2 and the regulating motor frame 3, and the output shaft end of the regulating motor 10 is equipped with an regulating screw 5 through a connecting sleeve 7, The top end of the adjusting screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com