Method for mfg. high strengthening environmental protection fireproof glass

A technology of fireproof glass and production method, which is applied in glass tempering, glass manufacturing equipment, glass production and other directions, can solve the problems of poor fireproof stability of glass, difficulty in mass production, environmental impact, etc., and achieves processing conditions conveniently and quickly , The effect of eliminating edge stress and stabilizing fire stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

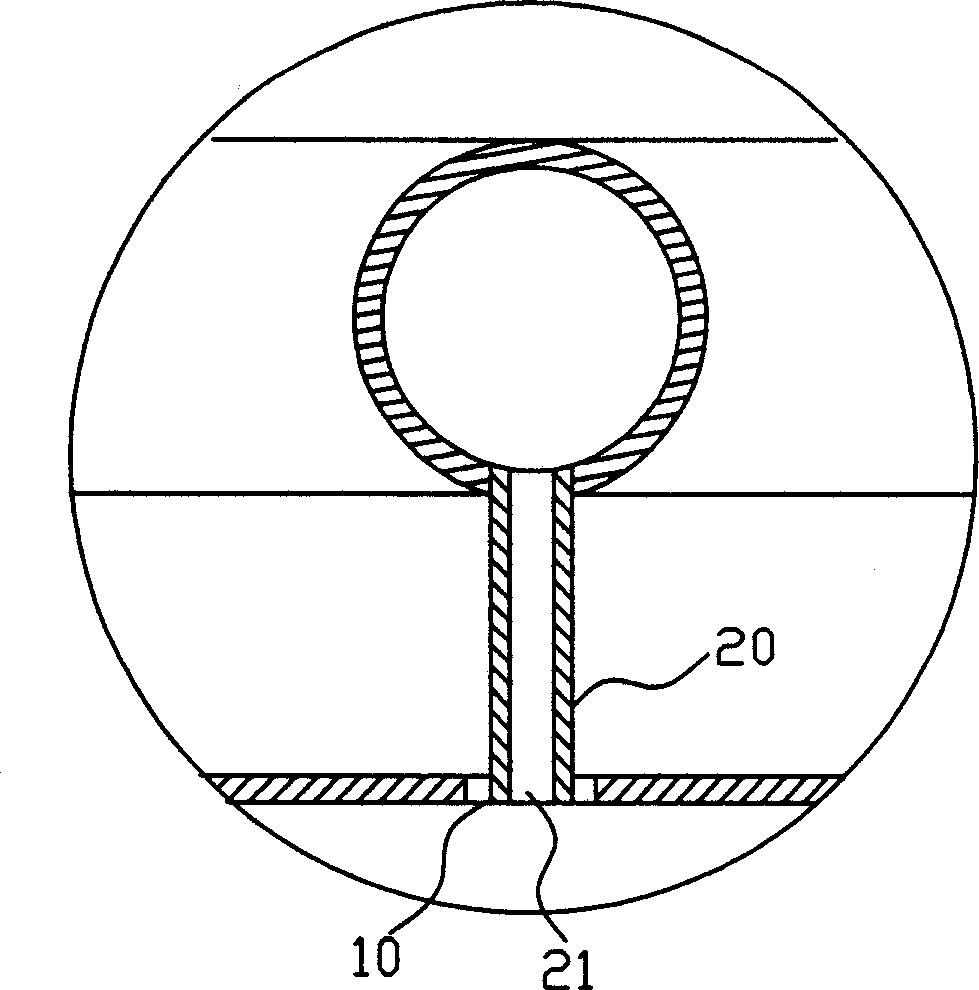

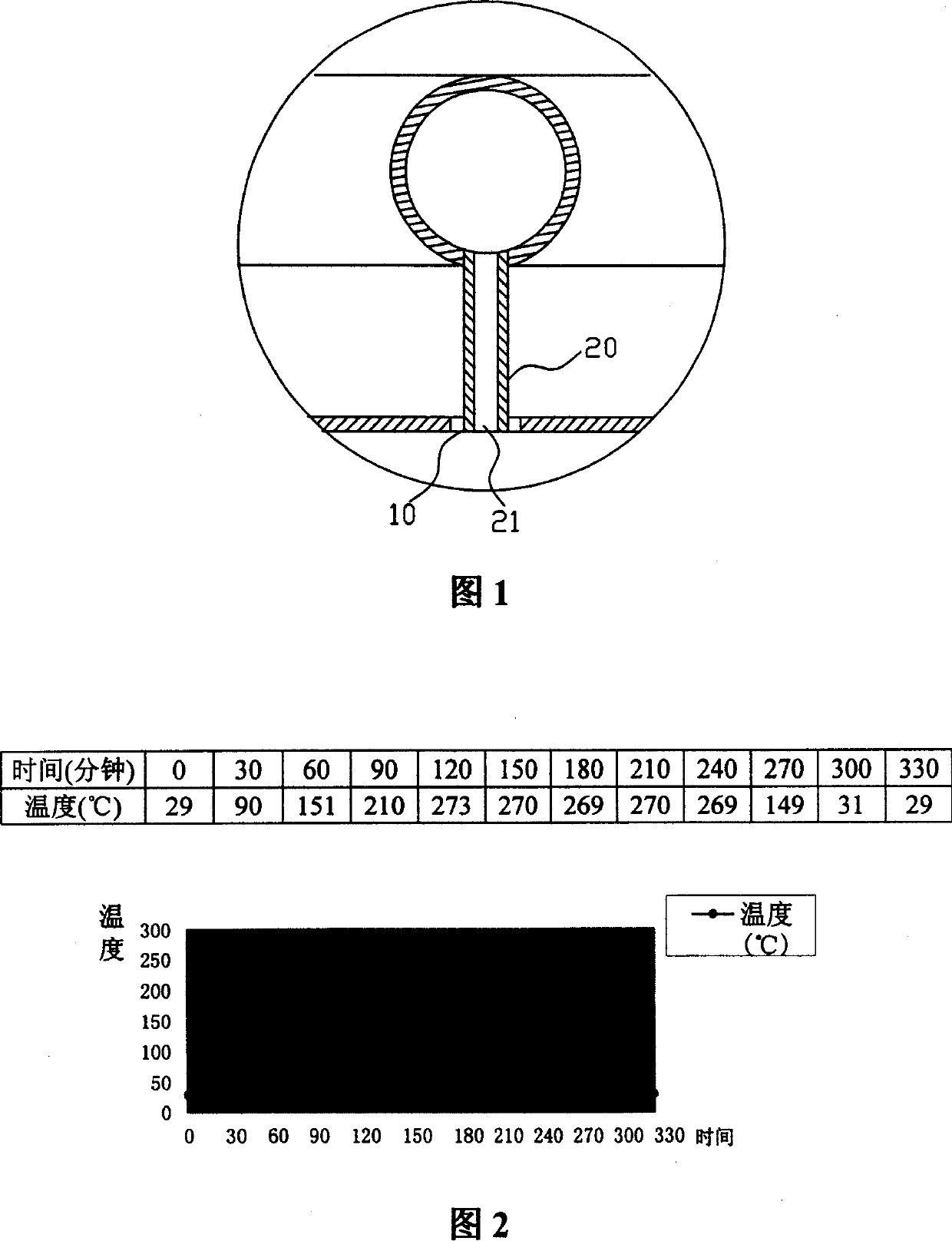

[0017] Below in conjunction with the manufacture method of 6mm fireproof glass, the present invention will be further described:

[0018] 1. Cut, finely grind and fillet the 6mm white glass (float glass) substrate to eliminate edge stress and clean it;

[0019] 2. Set the temperature of the upper part of the tempering furnace to 660°C, the temperature of the lower part to 680°C, the heating time to about 300-380s, and the furnace speed to 400mm / s. The glass is sent into a special tempering furnace and heated to the critical state of softening point;

[0020] 3. Set the air row at a height of 50-60mm, and the air pressure in the center of the air nozzle is 6-8×10 5 Pa, the external wind pressure is between 7000 and 7700Pa. When the glass reaches the softening temperature, it is quickly released from the furnace and physically tempered under the action of high-intensity and uniform wind pressure from the special air exhaust nozzle to achieve the high-strength stress required fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com