Pavement planometer

The technology of a leveling instrument and a measuring wheel is applied in the field of engineering leveling instruments, which can solve the problems of large measurement error and poor automatic leveling ability of the body, and achieve the effects of simple operation, strong leveling ability and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

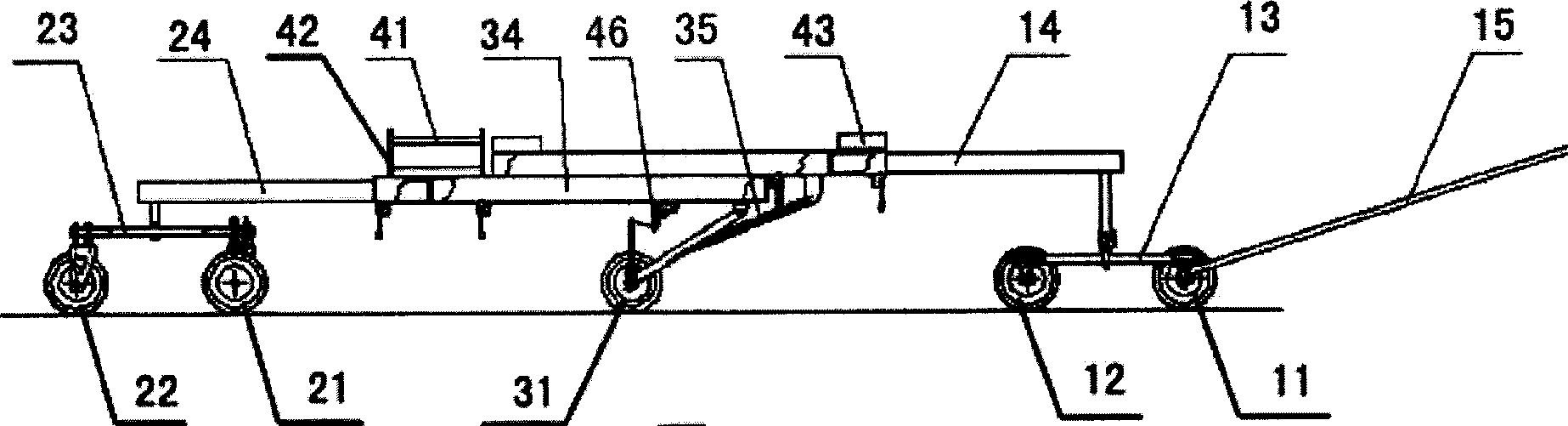

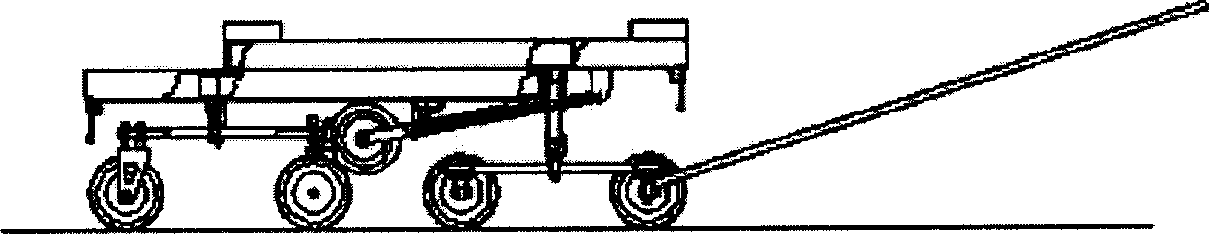

[0031] Examples see figure 1 , 2 , 3, 4, the body of this road leveling instrument is an eight-wheel retractable leveling structure, the body is fixedly connected to the main engine, and the specific structure of the body part is as follows:

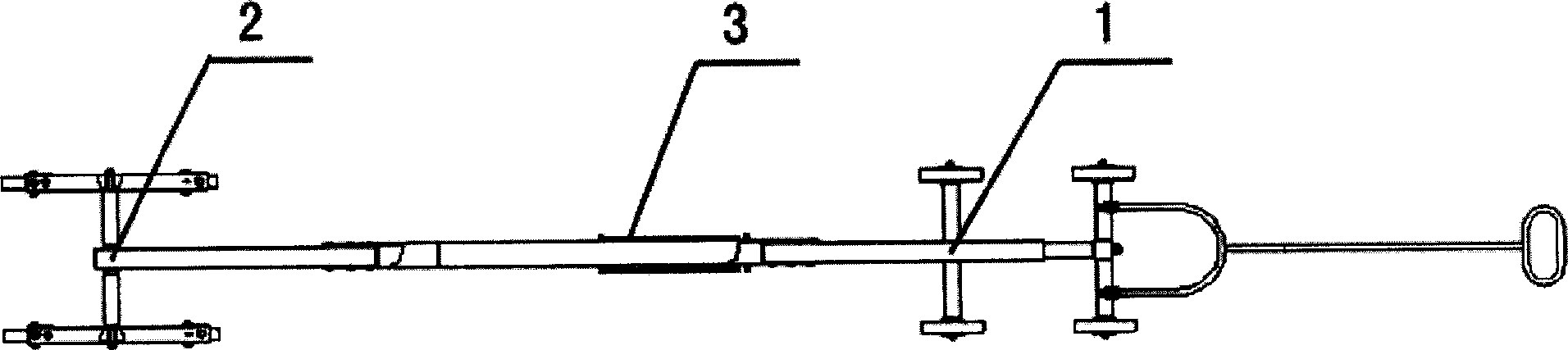

[0032] The composition of front wheel group 1: four front wheels 11,12 are connected with front wheel frame 13, connect traction frame 15 at the front part of front wheel frame, connect the front beam 14 that extends backward at the front wheel frame top, front The rear end of the beam is inserted and stretched in the middle beam 34 .

[0033] The composition of rear wheel group 2: four rear wheels 21,22 are connected with rear wheel frame 23, connect the rear beam 24 that extends forward at the rear wheel frame top, the rear beam front end inserts and stretches in the middle beam 4.

[0034] see Figure 7 , 8 , 9, the composition of above-mentioned rear wheel frame: connect two small longitudinal beams 25 of two side front wheels, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com