Process for preparing sodium azlocillin

A technology of azlocillin sodium and ampicillin, which is applied in the field of drug preparation, can solve the problems of long method steps, harsh reaction conditions, and high operating conditions, and achieve the effect of solving the problem of "three wastes" treatment, mild reaction conditions, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

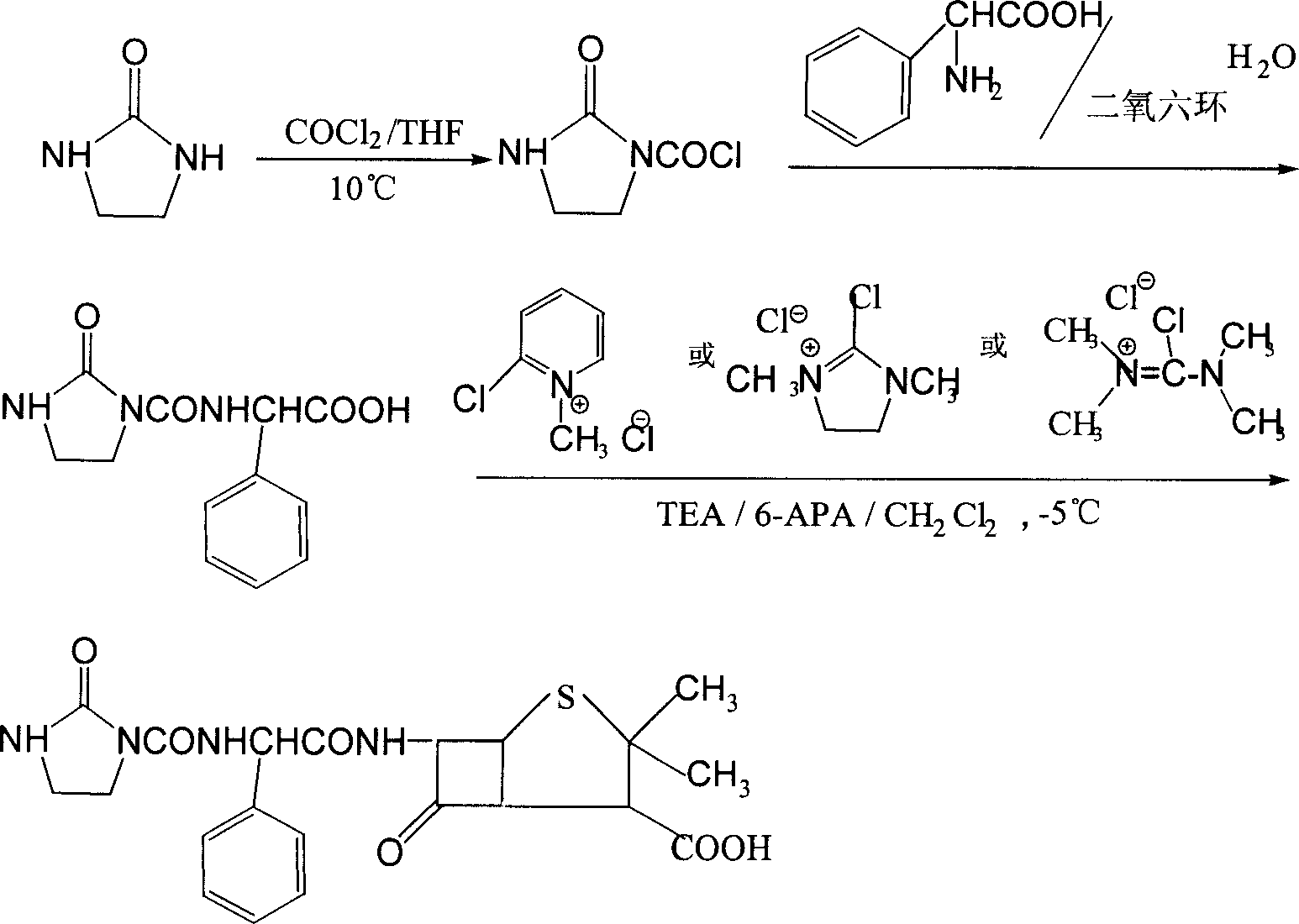

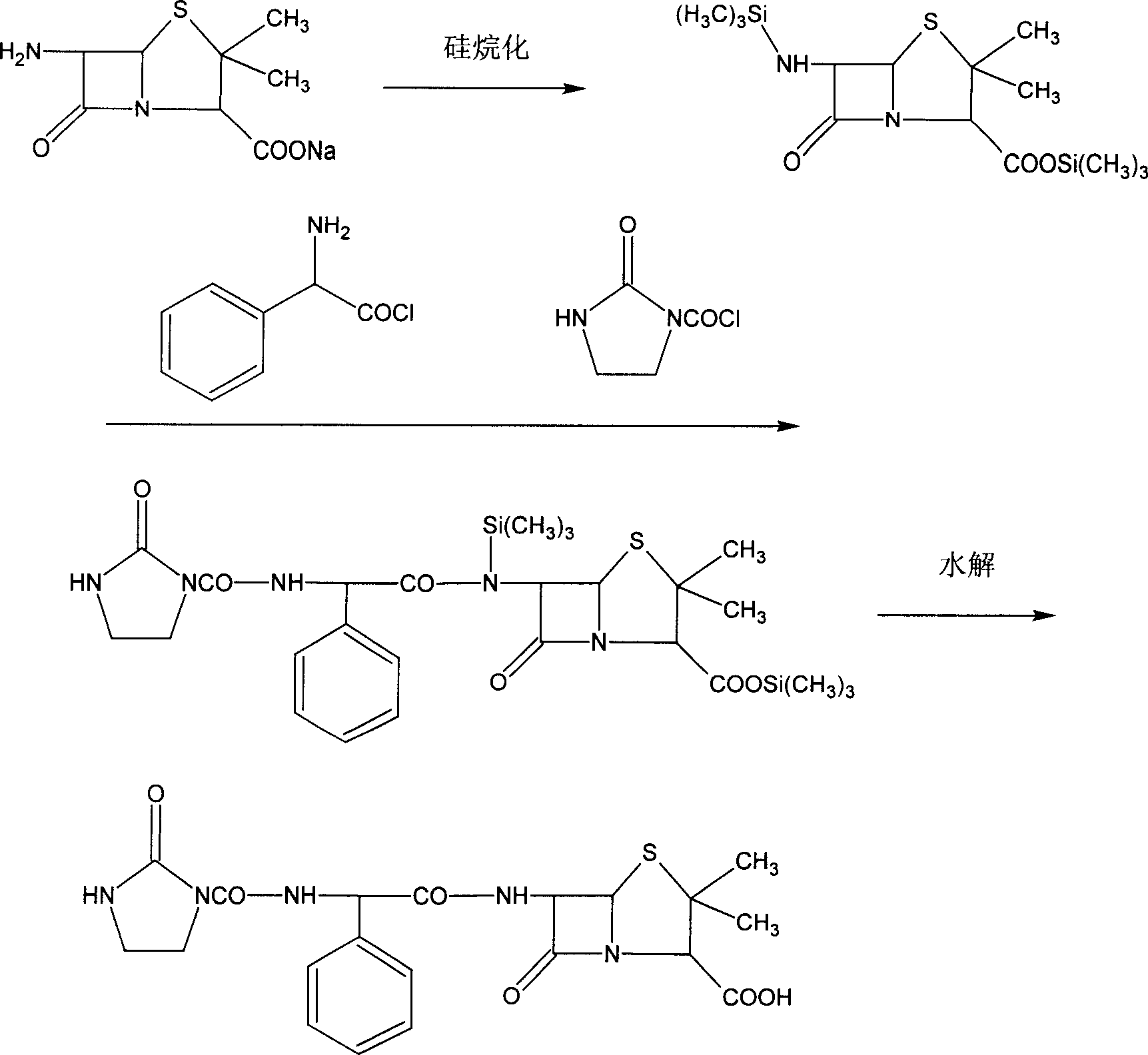

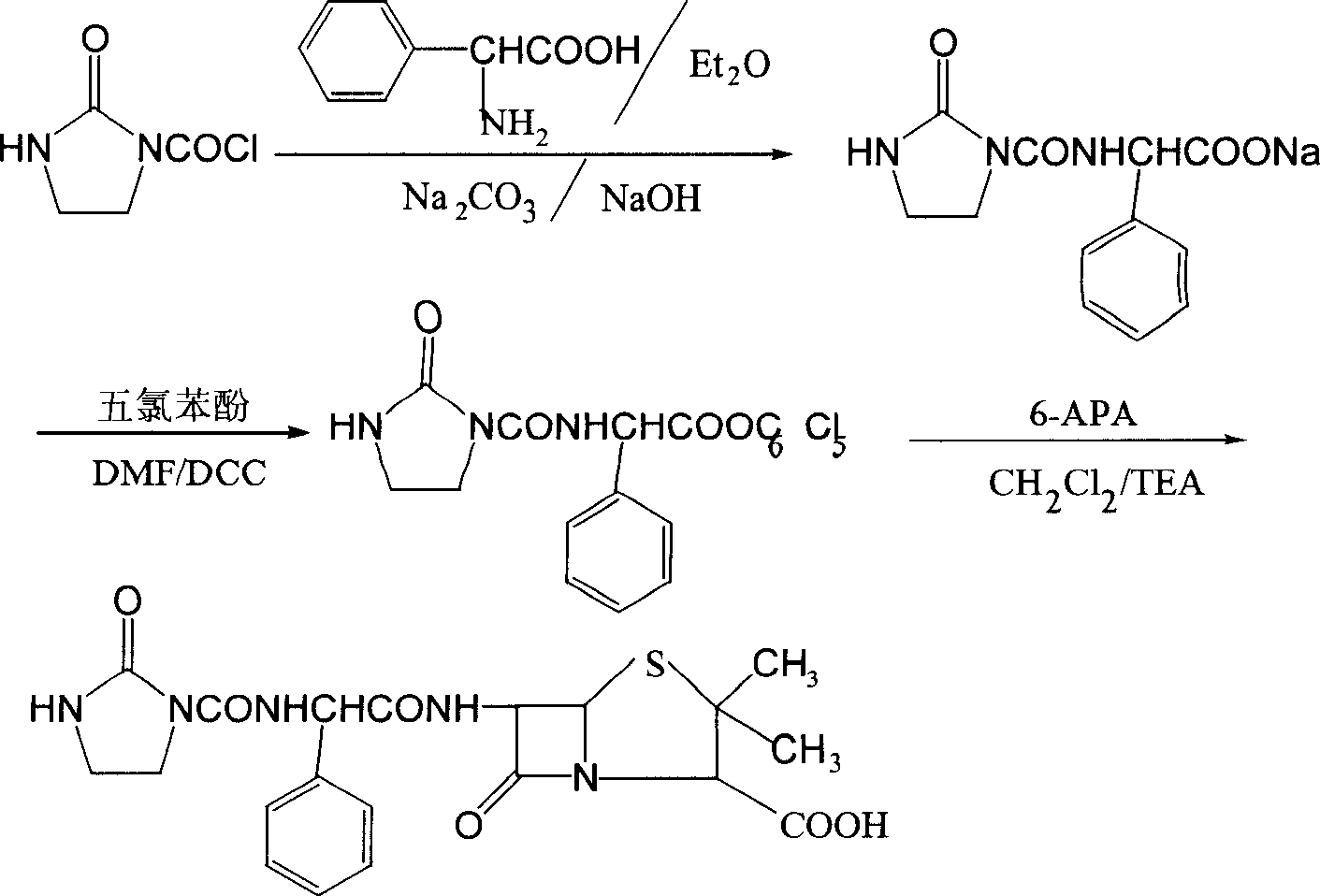

Method used

Image

Examples

Embodiment 1

[0042] (1) Raw material

[0043] raw material name

Feeding amount

molar weight

The molar ratio of

Remark

1400g

3.47

1.05

Deionized water

14L

490g

3.3

1

506mL

3.47

1.05

17L

368g

2.3L

1.47L

ethyl acetate

6L

Sodium isooctanoate

608.5g

3.64

1.1

ethyl acetate

5L

Washed products

[0044] (2) Process steps

[0045] Add 14 liters of water into a 50-liter reaction tank, cool to 4°C, add 1400g of ampicillin while stirring, slowly add 506ml of triethylamine dropwise at 4°C, and finish the dropwise addition in about half an hour, continue to stir for half an ho...

Embodiment 2

[0049] (1) Raw material

[0050] raw material name

Feeding amount

molar weight

The molar ratio of

Remark

1467g

3.64

1.10

Deionized water

14L

490g

3.3

1

530mL

3.64

1.10

ethyl acetate

17L

368g

2.3L

1.47L

ethyl acetate

6L

Sodium isooctanoate

636.2g

3.83

1.15

ethyl acetate

5L

Washed products

[0051] (2) Process steps

[0052] Add 14 liters of water into a 50-liter reaction tank, cool to 0°C, add 1467g of ampicillin while stirring, slowly add 530ml of triethylamine dropwise at 0°C, continue stirring for half an hour, and then the reaction solution becomes cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com