Method and device for preparing synthetic zeolite from flyash zero discharged waste alkali liquid

A technology for synthesizing zeolite and spent lye, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low investment costs and achieve the effects of protecting the environment, saving alkali costs, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

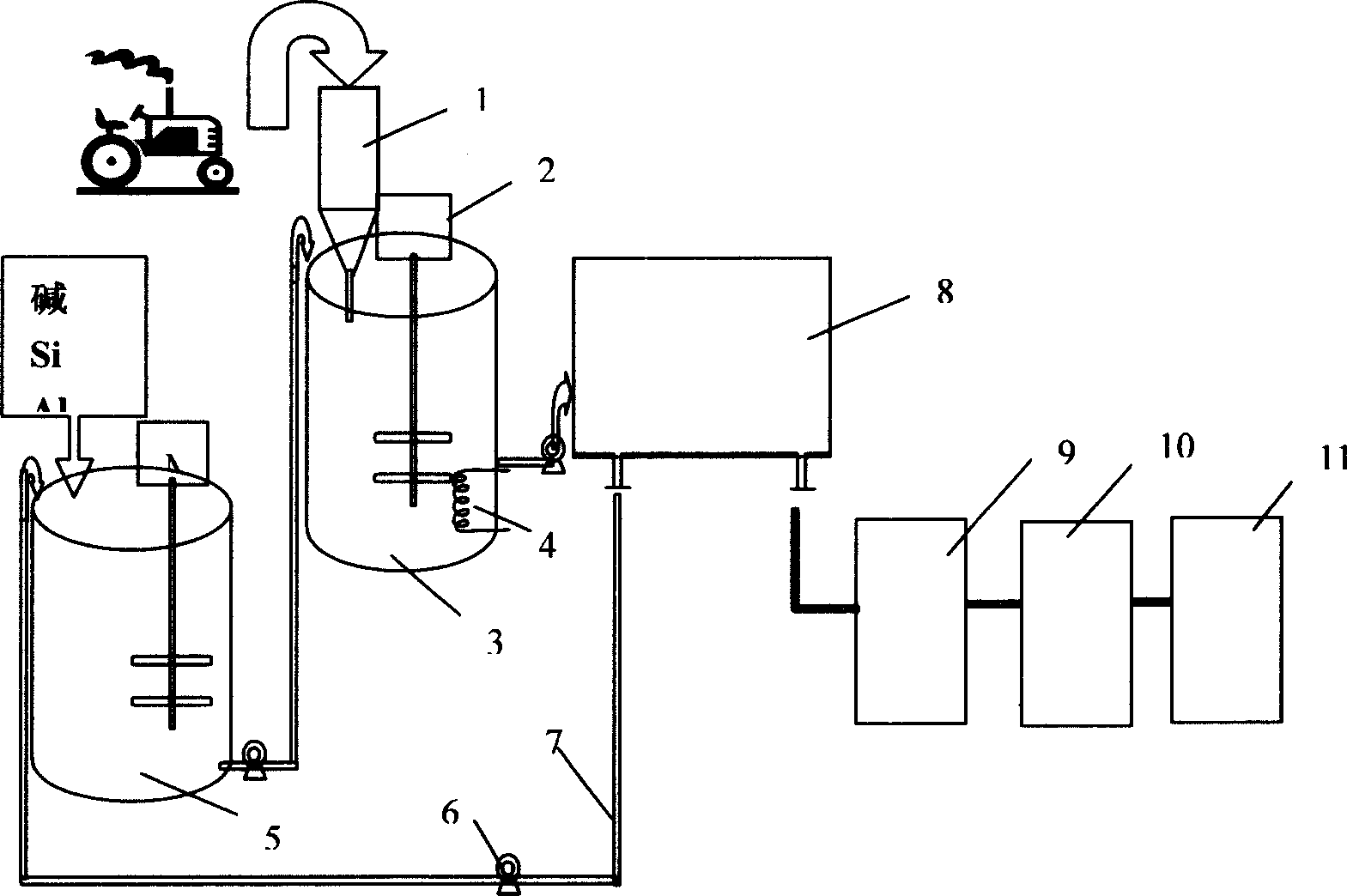

[0018] The preparation device structure that embodiment adopts is as figure 1 As shown, it mainly includes a zeolite synthesis reaction tank 3, a solid-liquid separation and dehydration tank 8 and a dissolution tank 5, and the dissolution tank 5 is connected to the zeolite synthesis reaction tank 3 and the solid-liquid separation and dehydration tank 8 through flexible hoses 7 respectively, and connected to the connecting pipe respectively. Metering pump 6 is set on the road. The top inlet of the zeolite synthesis reaction tank 3 is equipped with a fly ash raw material metering device 1, the interior of the zeolite synthesis reaction tank 3 is equipped with a stirring device 2, the lower part of the zeolite synthesis reaction tank 3 is provided with a heater 4, and the outlet of the zeolite synthesis reaction tank 3 is passed through a metering The pump 6 is connected to the solid-liquid separation and dehydration tank 8, and the solid-phase zeolite product outlet of the solid...

Embodiment 1

[0021] The solid waste fly ash remaining after coal combustion is used as the raw material, weighed by the fly ash raw material measuring device 1 , and put into the zeolite synthesis reaction tank 3 . Prepare 1M (molar concentration) NaOH solution in the dissolving tank 5, send it into the zeolite synthesis reaction tank with a metering pump at a liquid-solid ratio of 6, fully mix the two with the stirring device 2, and use the heating device 4 to make the zeolite synthesis reaction The tank contents are kept at a temperature of 95° C., and reacted under this condition for 24 hours. The reaction product is sent into the dehydration tank 8 for solid-liquid separation with a metering pump, where the solid phase and liquid phase are separated. The solid phase is washed in a washing tank 9 and dried in a drying device 10 to obtain a zeolite product. Carry out sub-packaging at finished product bagging place 11, then leave the factory. The alkalinity of the waste lye produced by t...

Embodiment 2

[0023]The solid waste fly ash remaining after coal combustion is used as the raw material, weighed by the fly ash raw material measuring device 1 , and put into the zeolite synthesis reaction tank 3 . Prepare 2.5M (molar concentration) NaOH solution in the dissolving tank 5, and send it into the zeolite synthesis reaction tank 3 with a metering pump at a ratio of 4 to the liquid-solid ratio, fully mix the two with the stirring device 2, and use the heating device 4 to make the zeolite The content of the synthesis reaction tank was kept at a temperature of 120° C., and reacted under this condition for 8 hours, and the reaction product was sent into the dehydration tank 8 for solid-liquid separation with a metering pump, where the solid phase and liquid phase were separated. The solid phase is washed in the washing tank 9 and dried by the drying device 10 to obtain the zeolite product, which is packaged at the finished product bagging place 11 and then shipped out. The alkalinit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com