High profile balable coils and innersprings

A coil and built-in technology, which is applied in the direction of springs, spring mattresses, springs/shock absorbers, etc., can solve problems such as axial alignment, coil axial instability, and coil aggravation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

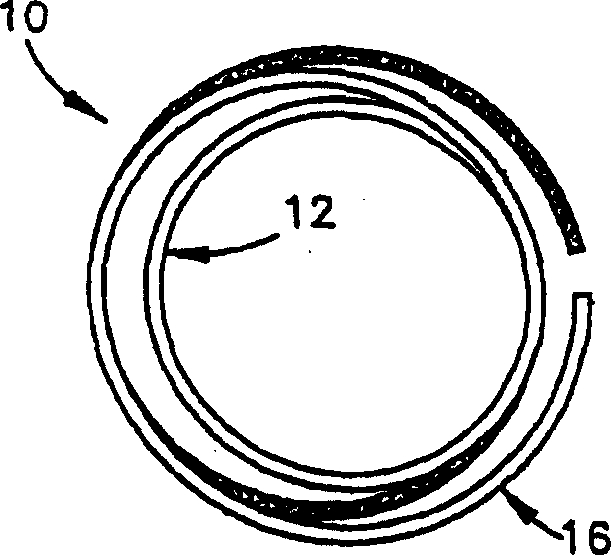

[0014] Referring to the drawings, there is shown a tall profile innerspring coil generally indicated at 10 having an overall ultimate end-to-end length or height dimension generally in the range of six and three-quarters to seven and one-half inches (or approximately 170 -190mm range). The coil 10 is formed from helical form wire (eg, 12-16 gauge) as a helix 13 with adjacent end helices 16 at opposite ends of the coil body. In this particular embodiment, there are three helices or turns forming the coil body, including intermediate helices 14 a and 14 b , and central helix 12 . Another embodiment of the coil of the present invention may be constructed in a different configuration, eg a different number of helices or turns, and a different shape of the coil ends, as described further below. In the particular embodiment of a five-turn helical coil, the central helix 12 has the smallest diameter, and the diameters of adjacent intermediate helices 14a and 14b become larger by a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com