Copper sputtering targets and methods of forming copper sputtering targets

A technology of sputtering targets and semi-finished products, which can be used in sputtering coating, transportation and packaging, vacuum evaporation coating, etc., and can solve problems affecting the quality of sputtering films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

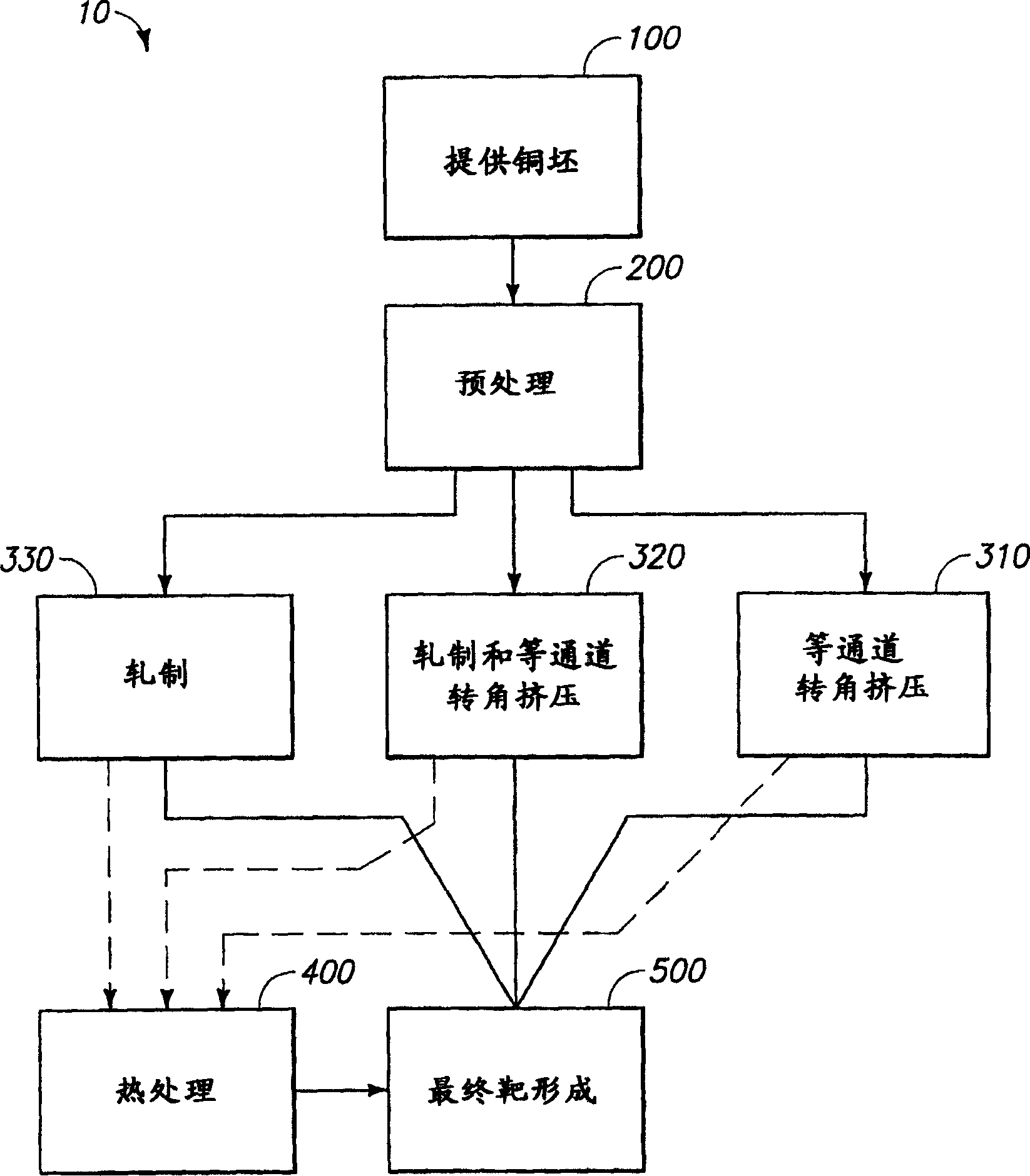

Method used

Image

Examples

Embodiment 1

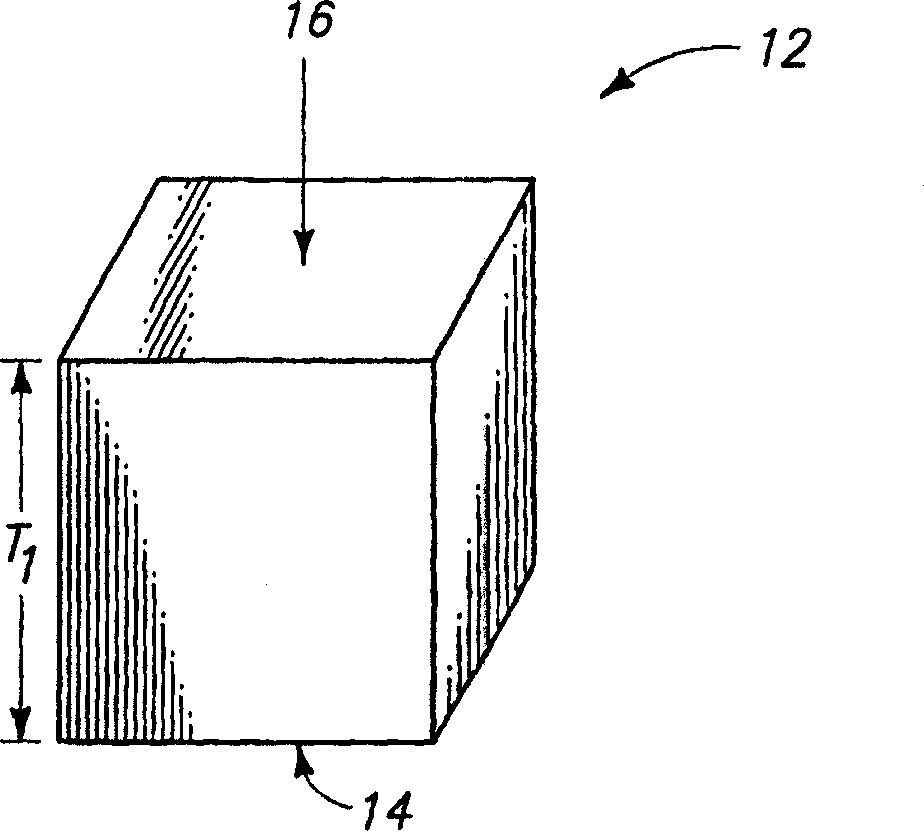

[0084] Embodiment 1: Manufacture high-purity copper monolithic sputtering target

[0085] A cast copper billet measuring 6 inches in diameter, 11 inches in length, and 6N pure was heated in an air furnace to a temperature of about 990°F and held for about 60 minutes. The billet is then hot forged to a final height reduction of 55-75%, immediately water quenched, using silica or graphite foil during the forging process. The ingot was then cold rolled for 16 passes, quenched after the initial 8 passes, for a total reduction of about 60 to about 80%. Cracking during cold rolling is prevented by performing the first 4 cold rolling passes with a reduction of about 5 to about 6% per pass. 13-16 passes were performed to produce a reduction of about 10 to about 11% per pass to obtain a small particle size. After cold rolling, the blank is recrystallized by heating to about 480°F for about 120 minutes. The semi-finished product is machined to make the final target. The resulting hi...

Embodiment 2

[0092] Embodiment 2: Manufacture copper alloy monolithic sputtering target

[0093] A billet of copper alloy having less than 10% Ag, Sn, Al or Ti is heated and maintained at a temperature of about 900 to about 1500°F for about 45 minutes. The billet is then hot forged to produce a final reduction of at least about 50%. Reheat some forging billets (depending on the alloy) for at least 10 minutes during forging. Immediately after final forging, the forged billet is water quenched. The ingot is cold rolled to a reduction of at least about 60% to form a semi-finished product which is recrystallized by heating to a temperature of from about 750 to about 1200°F for 120 minutes. The recrystallized blank is machined to form a monolithic target. Each target has an average particle size of about 15 to about 50 microns.

[0094] A specific target of a copper alloy with 0.3 atomic % Al was formed from a billet with a diameter of 6 inches and a length of 11 inches. Initially, the bil...

Embodiment 3

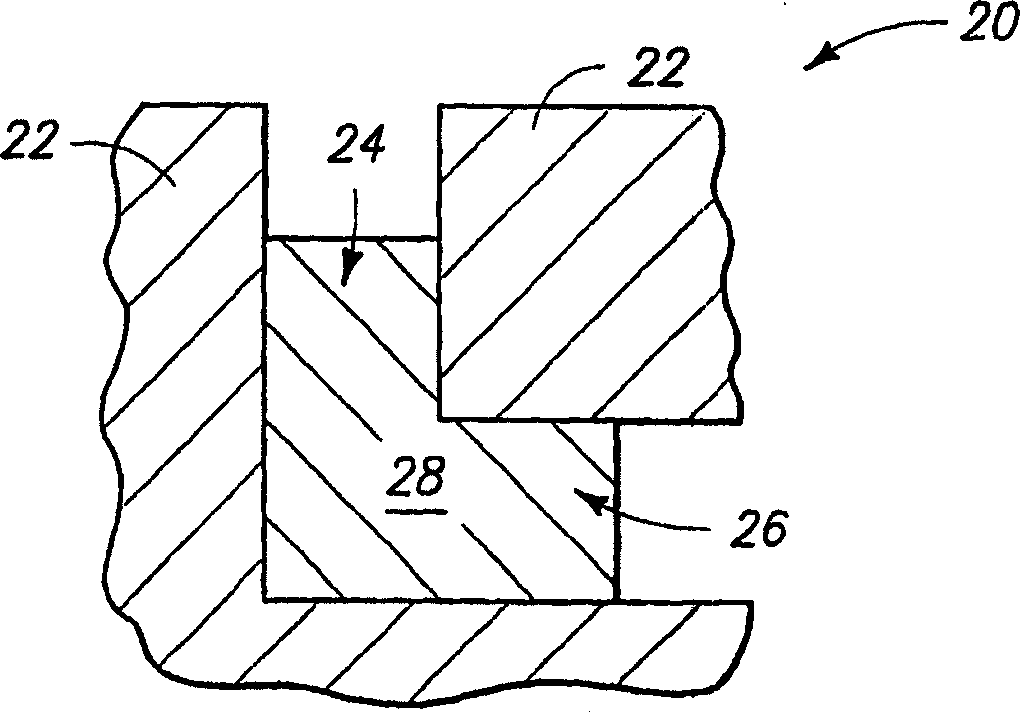

[0097] Example 3: Manufacture of Copper Alloy Diffusion Bonded Sputtering Target

[0098] A copper alloy billet was provided and processed as described in Example 2, except that it was cold rolled to a reduction of at least about 50%. The cold-rolled semi-finished product was joined to the CuCr support plate at a joining temperature of about 450° C. for about 120 minutes. Recrystallization of the alloy occurs during the joining process. The attached target has a particle size of less than about 30 microns and an attachment strength of up to about 30 ksi.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com