Portable Brinell hardness tester

A Brinell hardness tester, portable technology, applied in the field of hardness testing devices for metal materials, can solve the problems of complex structure, high cost, inability to carry out on-site testing, etc., and achieve the effect of simple operation and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

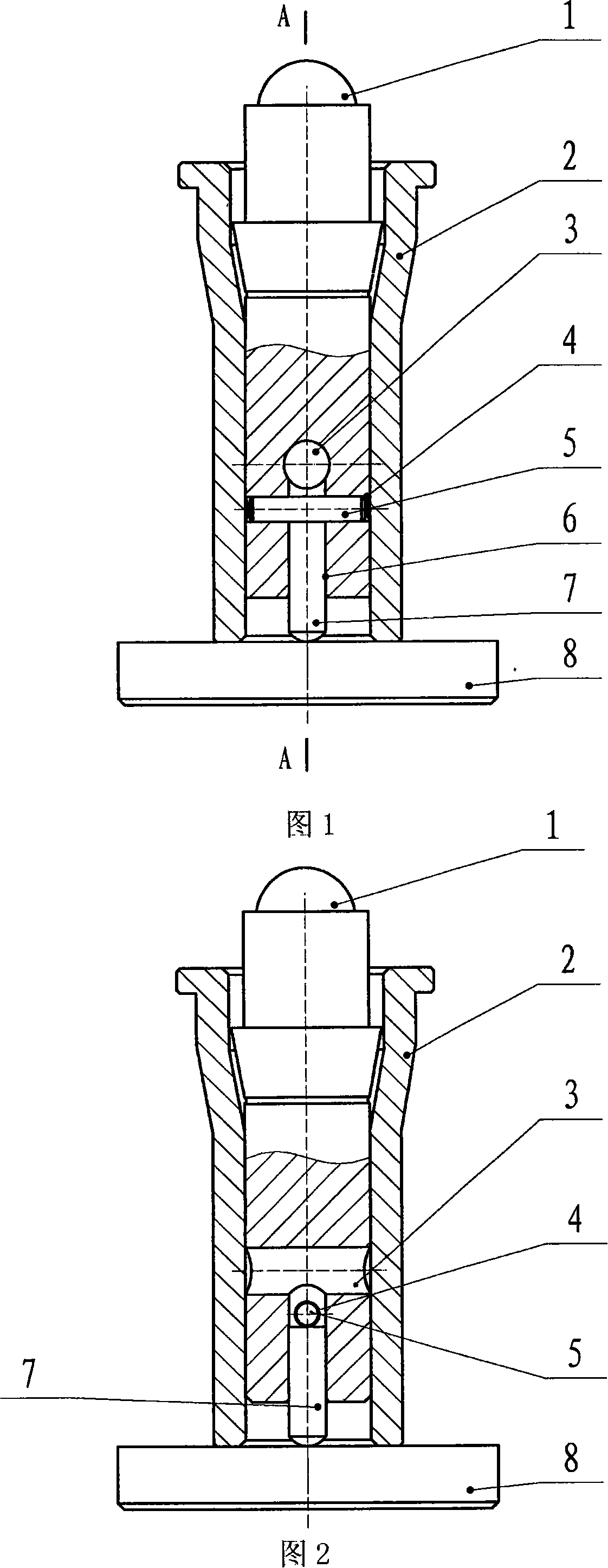

[0023] The structure of the portable Brinell hardness tester of the present invention is shown in Figure 1 and Figure 2. Put the shear pin 5 into the shear pin hole 4, put the indenter 7 into the indenter hole 6, and put the indenter support 1 into the sleeve in barrel 2. The lower end of the indenter 7 in the indenter pillar 1 is in contact with the surface of the sample 8, the upper end of the indenter 7 is in contact with the shear pin 5, and provides support for the entire indenter pillar 1 through the shear pin 5, so that the indenter pillar 1 is suspended on the sleeve In 2, the conical surface of the outer wall of the pressure head pillar 1 is higher than the conical surface of the inner wall of the sleeve 2 and leaves a gap.

[0024] When performing the hardness test, the portable Brinell hardness tester provided by the present invention is placed on the sample 8, and the test pressure is vertically applied to the top of the indenter pillar 1 . The test force is trans...

Embodiment 2

[0026] The test force of the portable Brinell hardness tester provided by the present invention can be applied dynamically, that is, the test force is applied by hitting the top of the indenter pillar 1 with a hammer.

Embodiment 3

[0028] The test force of the portable Brinell hardness tester provided by the present invention can be statically applied, that is, a test force is applied to the top of the indenter pillar 1 by using a C-shaped frame with a screw rod and a handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com