Lighting device

A lighting device and installation part technology, which can be applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as the increase of inspection equipment costs, and achieve the effect of simplifying structure and realizing miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

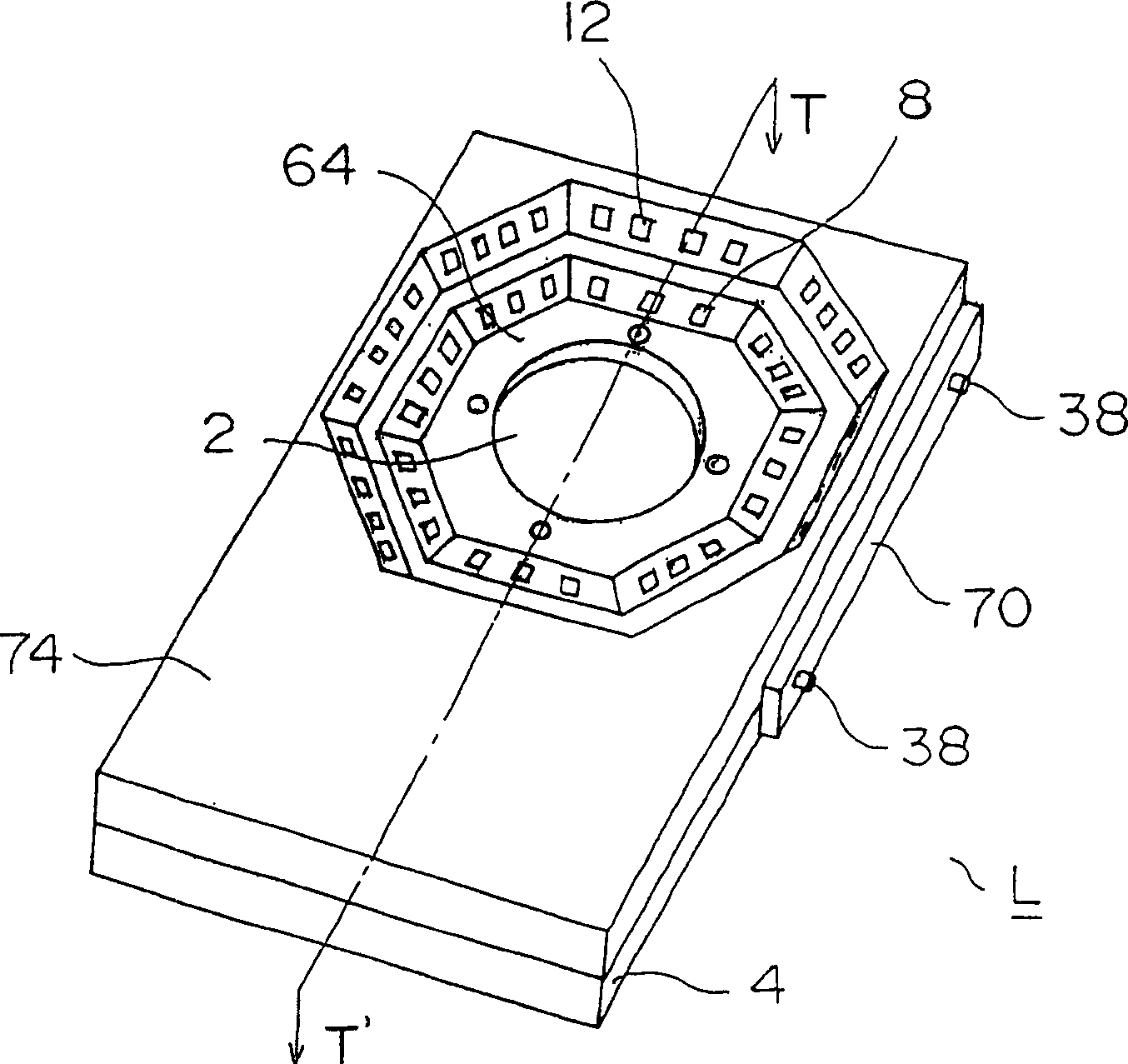

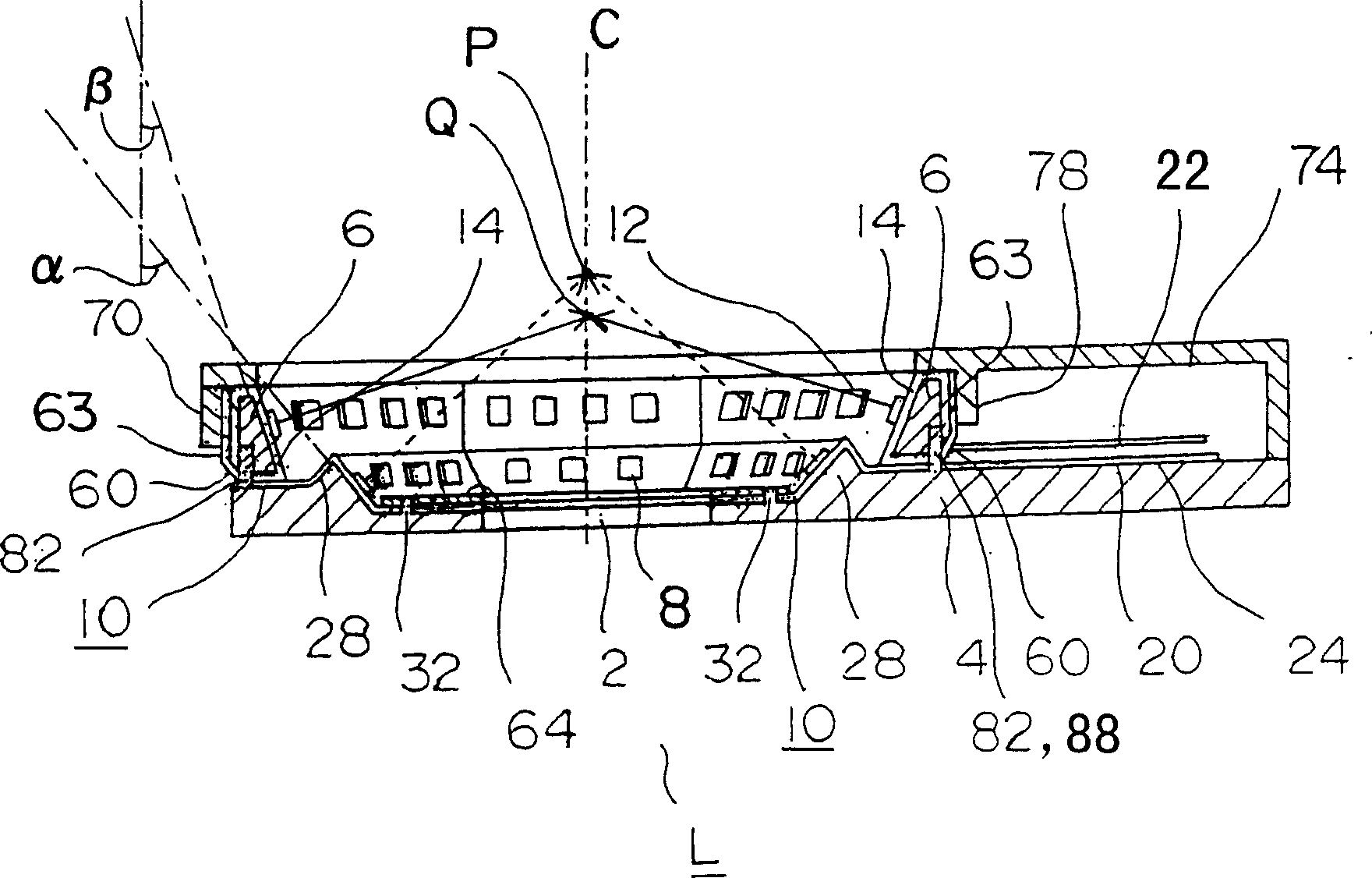

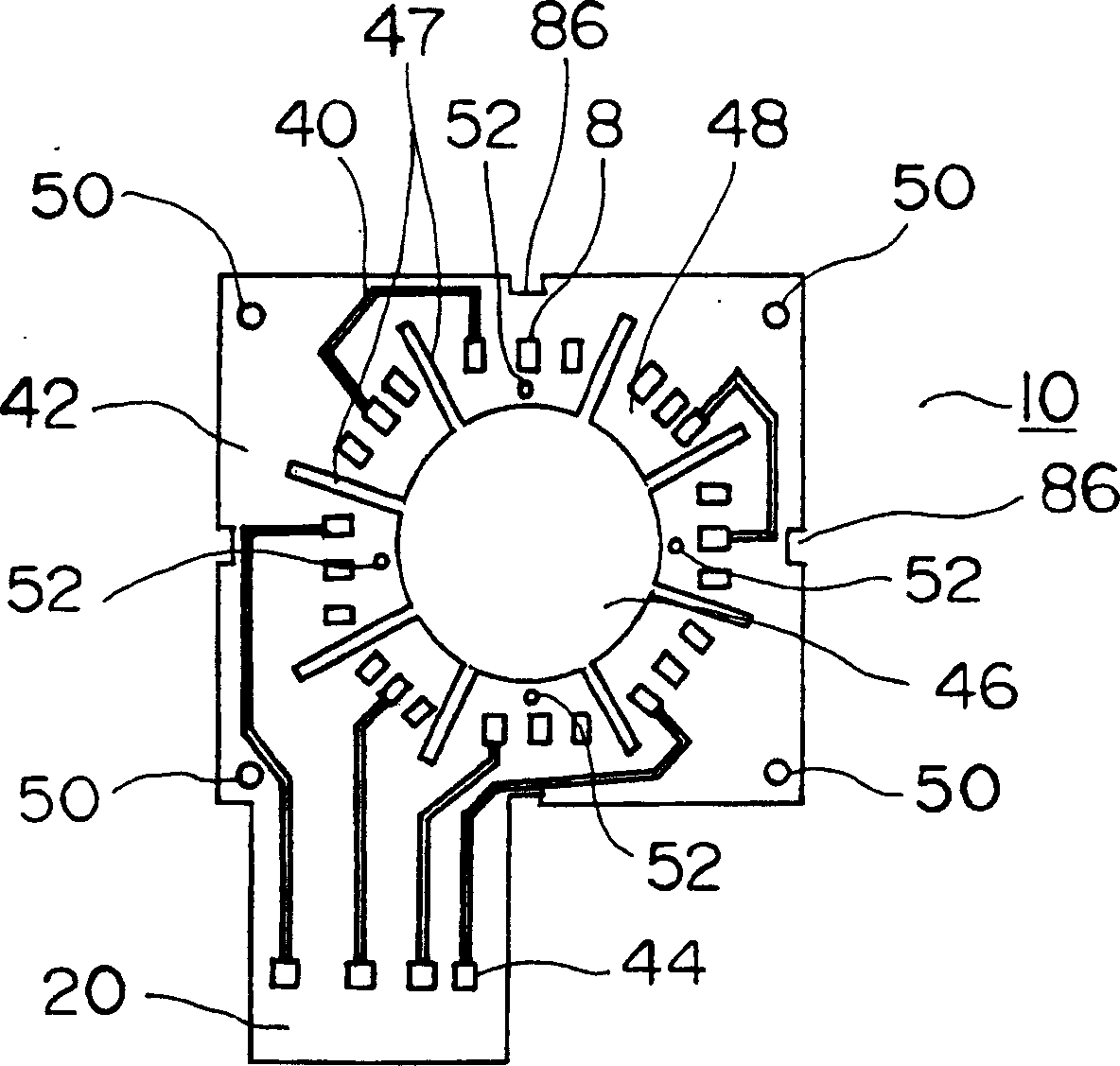

[0036] Hereinafter, one embodiment of the lighting device according to the present invention will be specifically described with reference to the drawings.

[0037] figure 1 is a perspective view showing the lighting device of the present invention, figure 2 yes figure 1 The cross-sectional view of the T-T' line in the middle, image 3 is a plan view showing the first sheet-shaped substrate, Figure 4 is a plan view showing the second sheet-shaped substrate, Figure 5 is an exploded perspective view illustrating a method of fixing the first sheet-shaped substrate to the first housing member, Figure 6 It is an exploded perspective view for explaining the method of fixing the second sheet-shaped substrate to the second housing member, and FIG. 7 is a cross-sectional view showing a state in which the second sheet-shaped substrate is mounted on the second housing member, Figure 8 It is a bottom view showing the state where the second sheet-shaped substrate is mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com