Electrochemical cell with flat casing and vent

An electrochemical, battery technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

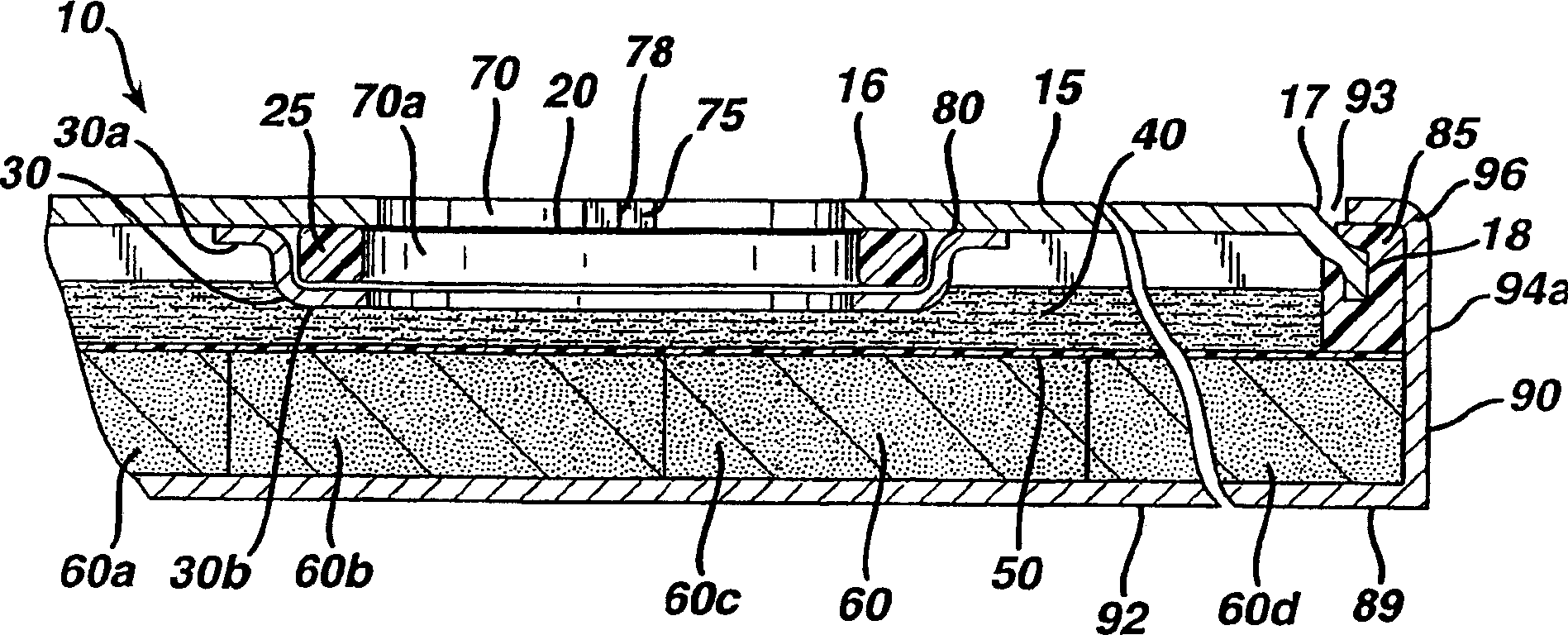

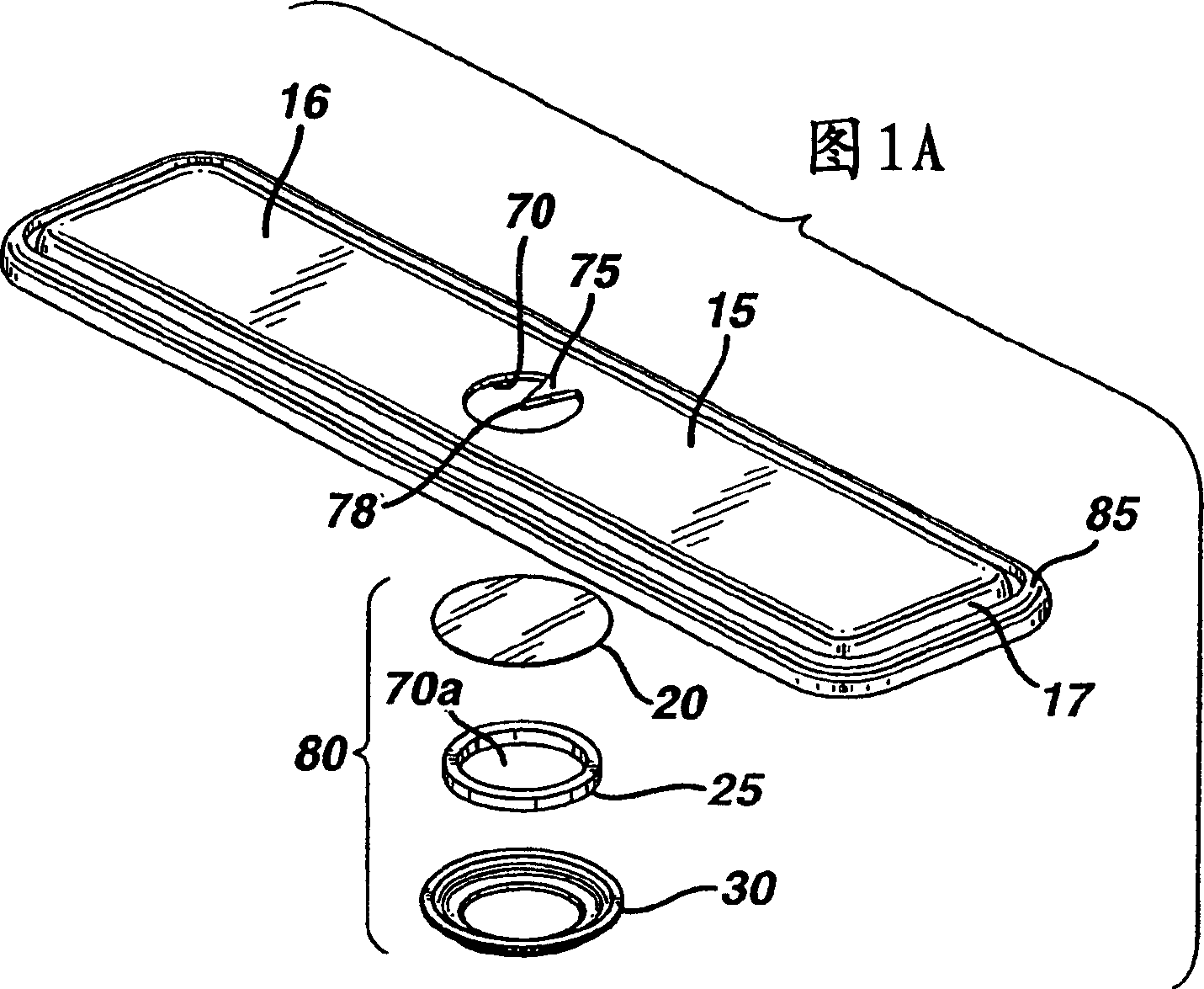

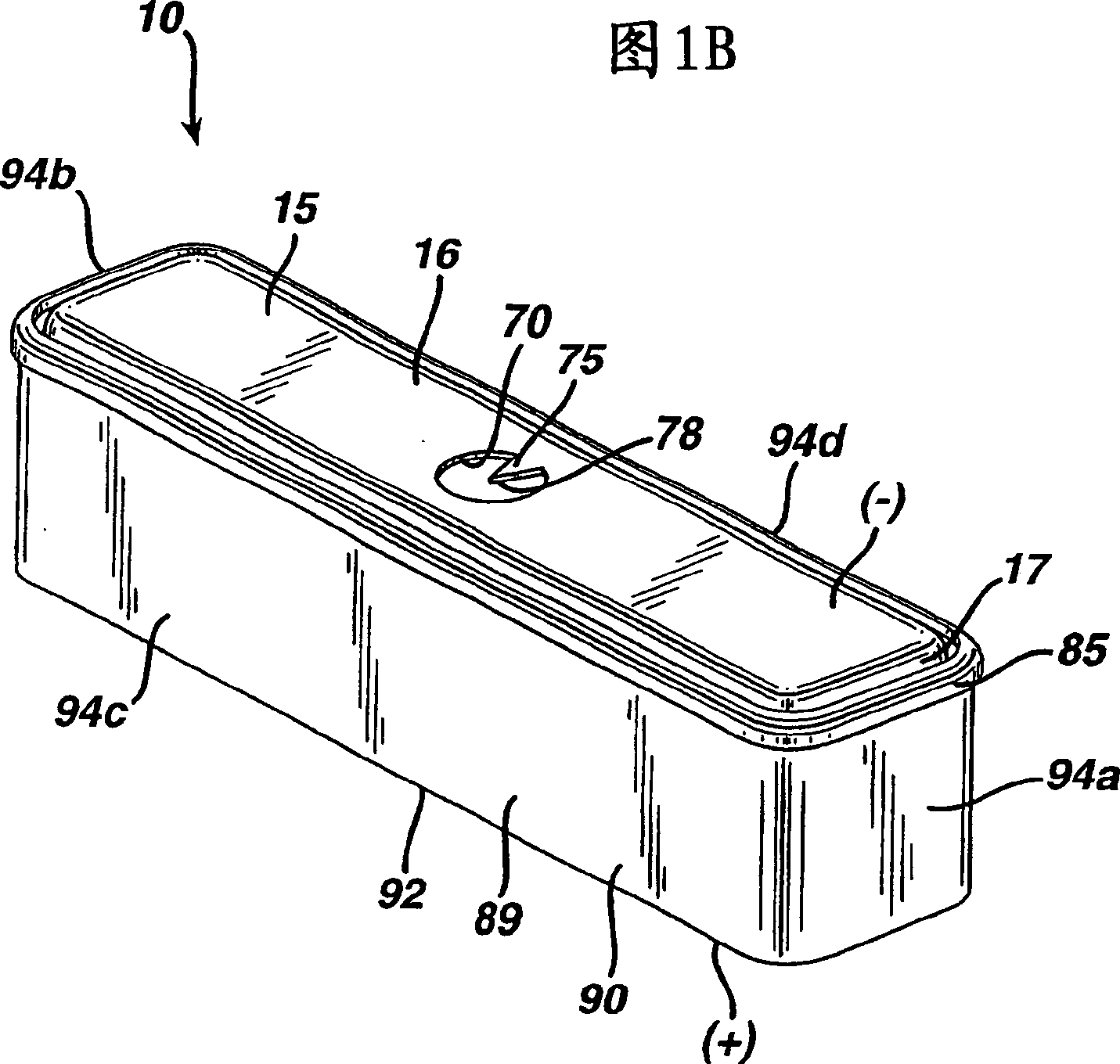

[0031] Figure 1~1 B shows an embodiment of the flat alkaline battery (alkaline battery) 10 of the present invention. Alkaline battery 10 ( Figure 1~1 B) includes an outer metal shell 89 having an elongated metal body surface, the main part of which has a flat polygonal shape. The housing 89 may have an overall shape of a polyhedron having a flat polygonal surface. In a preferred embodiment, the finished battery 10 has an overall shape of a cuboid (rectangular parallel body). For example, the shape and size of battery 10 may be equal to or similar to a 7 / 5F6 size (IEC standard) battery. This battery has figure 1 The overall cuboid shape shown in B has a length of about 67 mm, a width of about 17 mm, and a thickness of about 6 mm. With this shape and size, the battery 10 of the present invention can be used instead of a 7 / 5F6 size nickel metal hydride battery as a power source for electronic equipment such as Sony's model MZ-900 (MD) mini-disk player. Such alternative se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com