Composite contact, vacuum switch and method for manufacturing composite contact

A composite contact and mixture technology, which is applied in the direction of contacts, electric switches, contact materials, etc., can solve the problems of restraint limitation, inability to fully improve temperature characteristics, etc., and achieve high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

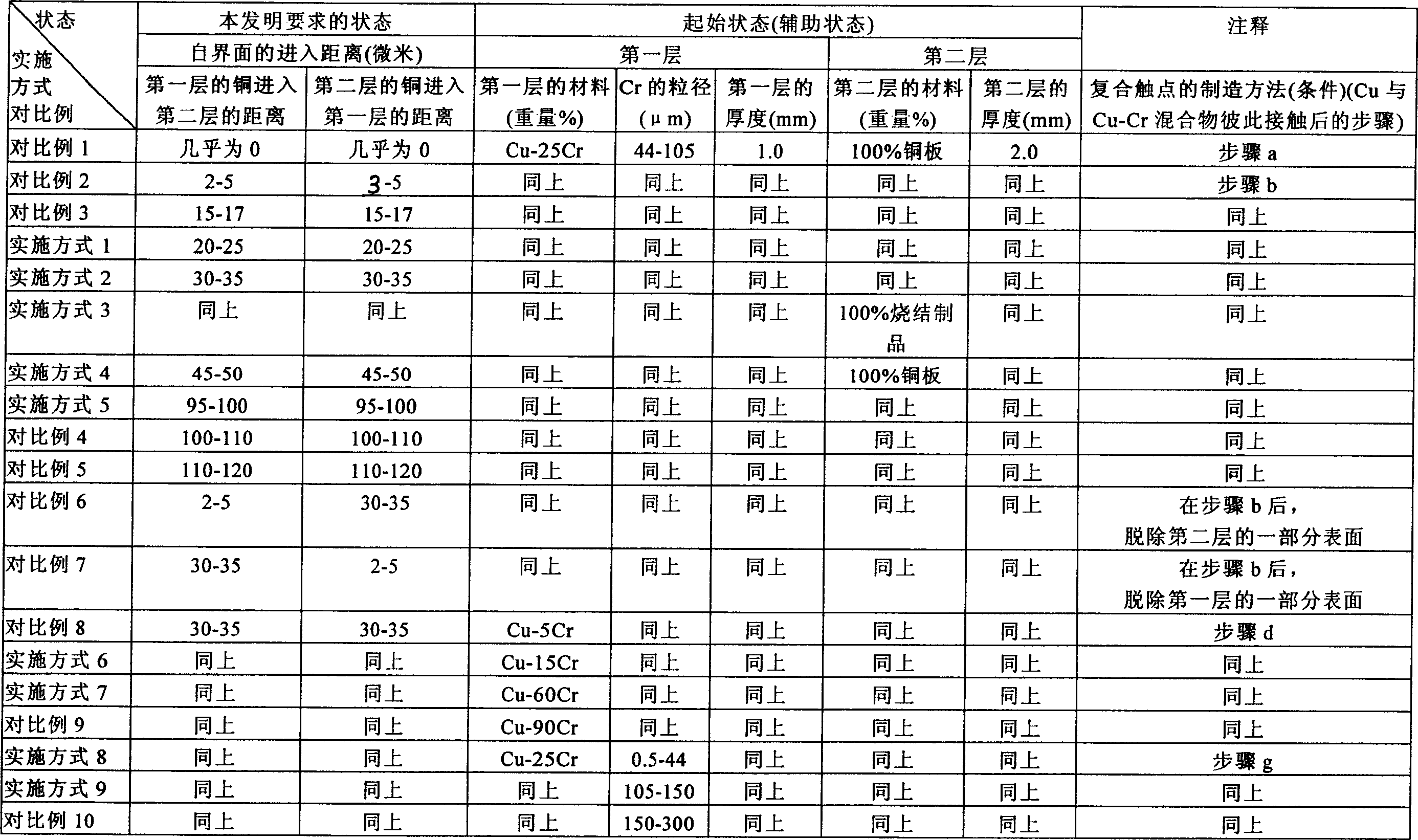

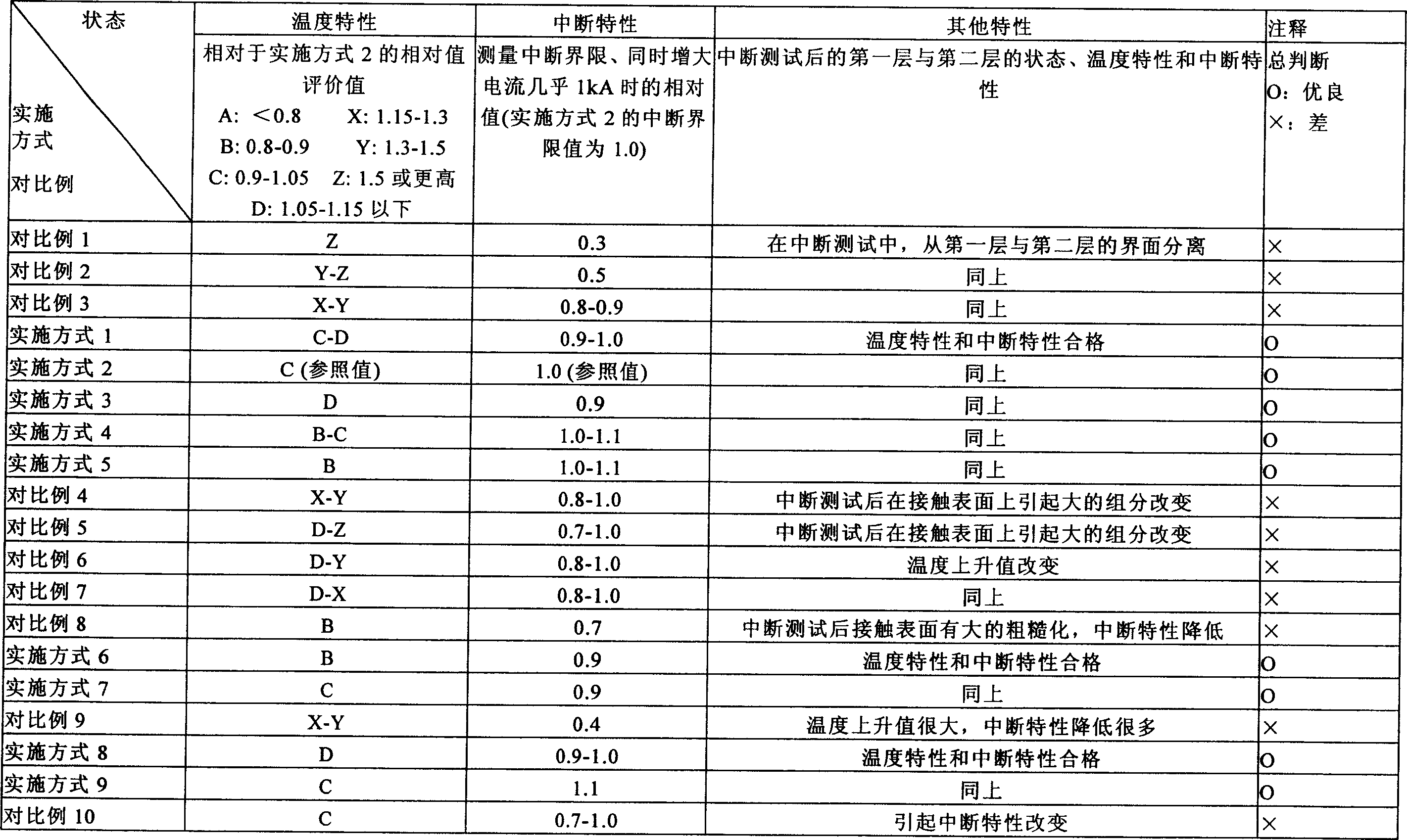

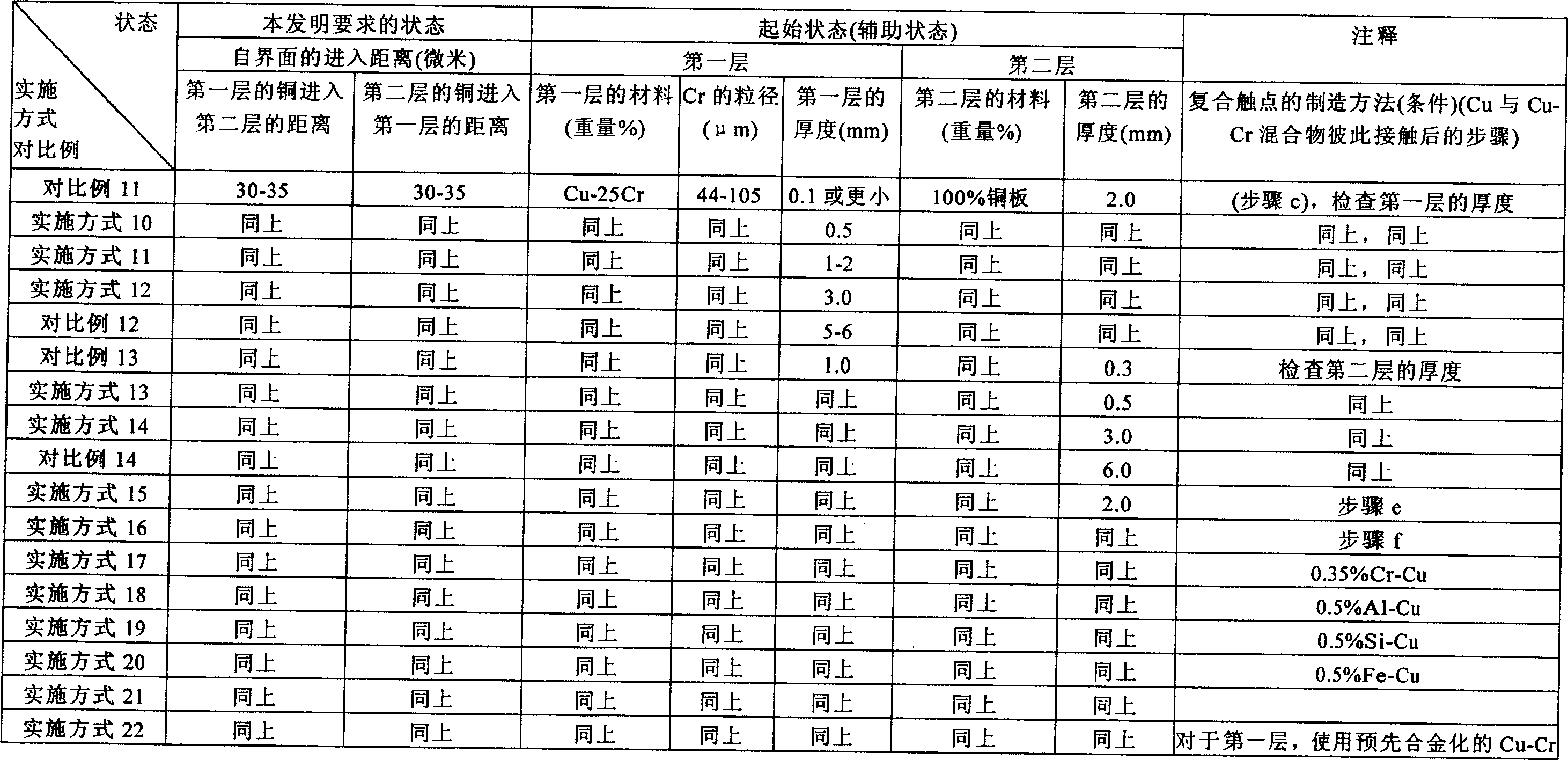

Embodiment 1-5 and comparative example 1-7

[0151] In these Examples and Comparative Examples, except Example 3, a copper plate was used as the copper of the second layer.

[0152] That is, a pure copper plate with a thickness of 2 mm was used as a representative material of the second layer, and a Cu-25%Cr alloy with a thickness of 1 mm was used as a representative material of the first layer.

[0153] Preheat the copper plate at 500°C or higher for 10 minutes or longer. The copper to be used in the Cu-Cr mixed powder is preheated at 350°C or higher for about 1 hour before use. Cr to be used in the Cu-Cr mixed powder is preheated at 1350°C or higher for about 30 minutes or longer before use.

[0154] For the first layer of copper and Cr, prepare such Cu-Cr mixed powder (first layer), wherein the Cr powder with an average particle diameter of 44-105 microns is the same as the copper powder with an average particle diameter in a predetermined ratio (25% by weight) Cr-Cu), mixed evenly. For the second layer of copper, ...

Embodiment 3

[0173] In Example 3, a copper sintered plate was used as the copper of the second layer.

[0174] That is: as the copper and Cr of the first layer, prepare such Cu-Cr mixed powder (first layer), wherein the Cr powder of average particle diameter 44-105 micron is the same copper powder with average particle diameter, with predetermined ratio (25 % by weight Cr-Cu), mixed evenly. As the second layer of copper, a copper sintered plate was prepared, which had 8.0 g / cm 3 Or higher relative density, and rolled into 2mm thick.

[0175] On top of the copper sintered product (second layer), place Cu-Cr mixed powder (first layer), these two layers remain unchanged (keep the load), and undergo a predetermined preliminary heating process (900-1150 ° C) for about For 1 hour (in step b), the Cu-Cr alloying of the Cu-Cr mixed powder (first layer) and the alloying of the interface between the first layer and the second layer are simultaneously achieved. Thus, a composite contact is obtaine...

Embodiment 6-7 and comparative example 8-9

[0177] As the first layer of copper and Cr, prepare such Cu-Cr mixed powder (first layer), wherein the Cr powder with an average particle diameter of 44-105 microns is the same as the copper powder with an average particle diameter in a predetermined ratio (5-90 % by weight Cr-Cu), mixed. As the copper of the second layer, a copper plate was prepared.

[0178] On top of the copper plate (2nd layer), place Cu-Cr mixed powder (1st layer), these two layers are in contact with each other as they are, (holding the load), and bonded to each other in such a way that at 6 t / cm 2 or lower pressure, such as 2 tons / cm 2 , subjected to preliminary pressurization, and then subjected to a preliminary heating process (900-1150°C) for about 1 hour, simultaneously achieving Cu-Cr alloying of the Cu-Cr mixed powder (first layer) and the relationship between the first layer and the second layer alloying at the interface. Thereby, a composite contact is obtained in which the two layers (firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com