Apparatus and method for cutting sheet-type work material using a blade reciprocated via a tuned resonator

A technology for processing materials and resonators, applied in the field of vibrating blades cutting said materials, can solve the problems of mechanism complexity, blade wear, difficulty in accurately controlling the blades, etc., and achieve the effects of low complexity, maintenance and operation economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

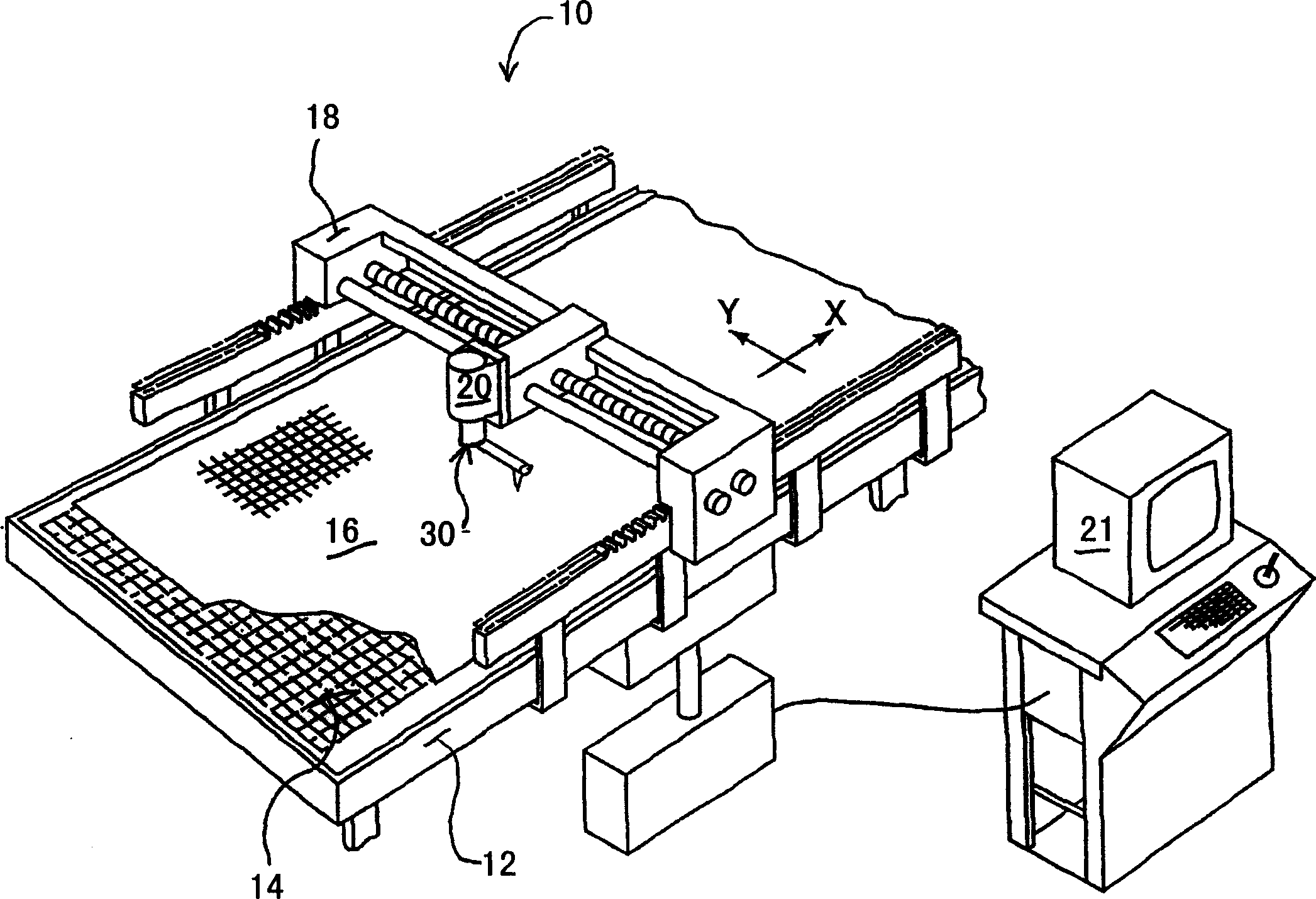

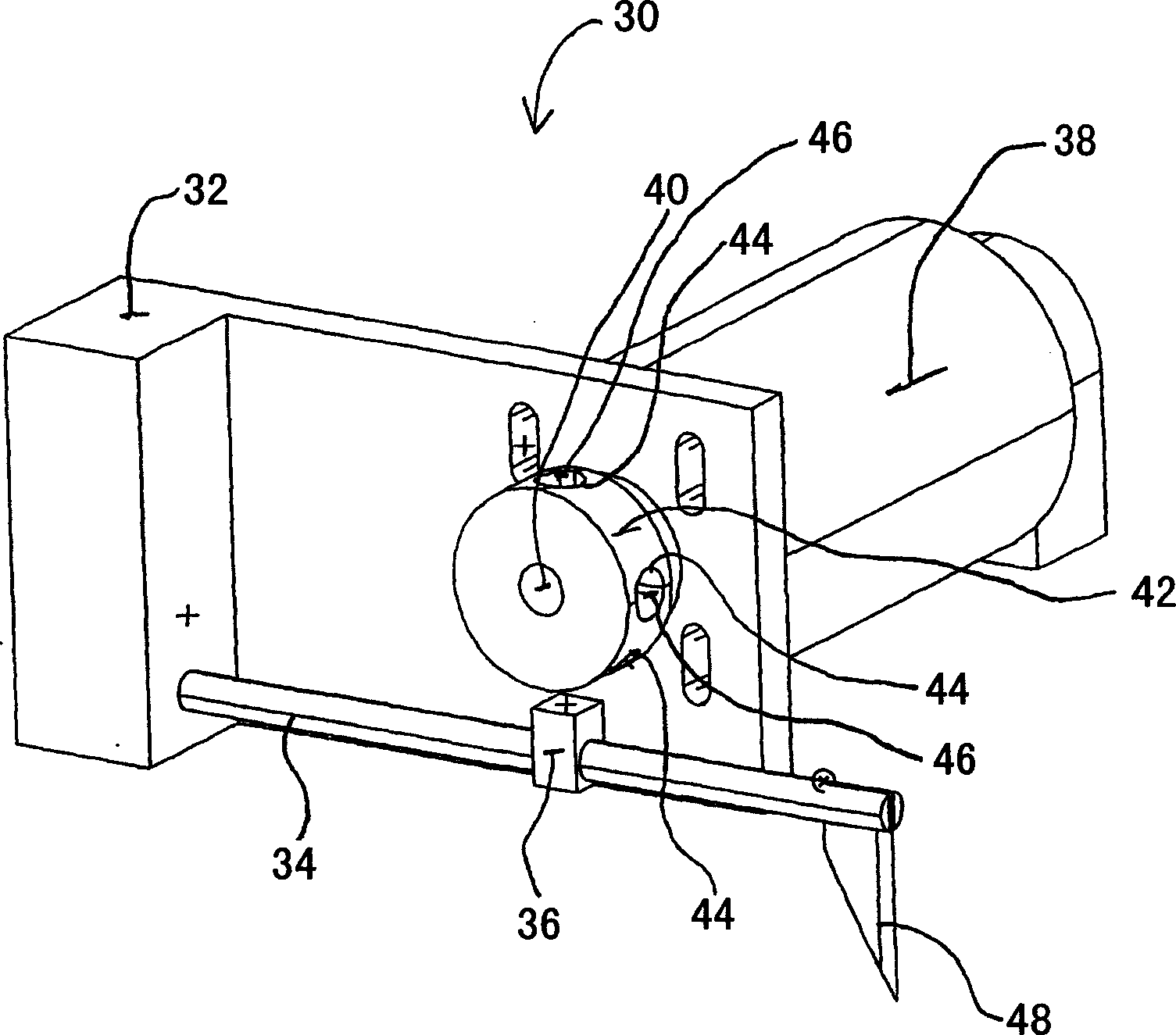

[0016] Such as figure 1 As shown, the cutting table, generally indicated by reference numeral 10, includes a frame 12 and a sheet-like process material support surface 14 adapted to carry at least one layer of process material 16, such as but not limited to Leather or vinyl film. A bracket 18 is attached to the frame for reciprocating movement in a first direction indicated by an arrow marked "X". The cutting head 20 is mounted to the carriage 18 and is movable back and forth along the carriage 18 in a second direction indicated by an arrow labeled "Y". Both carriage 18 and cutting head 20 move in response to commands from controller 21 . As will be described in more detail below, a reciprocating assembly, generally designated 30, is mounted to cutting head 20 and is movable between an operative position in which they engage the material 16 to be processed, and an inoperative position, In said non-working position they are lifted away from the processing material. During o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com