Horizontal pulverizer

A pulverizer and horizontal technology, which is applied in the field of horizontal pulverizers, can solve the problems of easy temperature rise of the bearings at both ends of the main shaft, reduced efficiency of the pulverizer, and smaller pressure difference of the sieve plate, so as to improve the efficiency of the pulverizer and the efficiency of the pulverizer Enhancement, strong suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

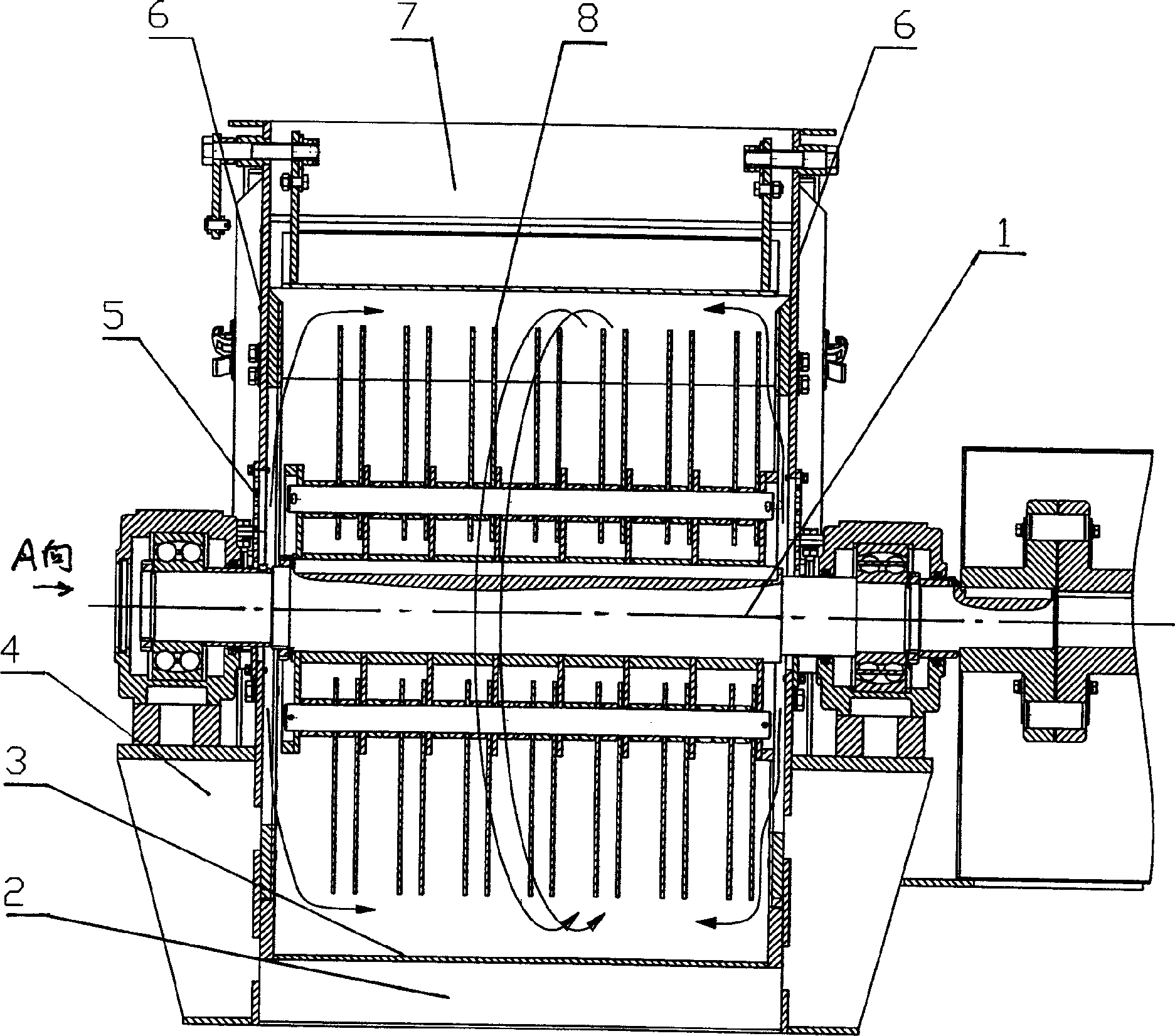

[0012] As shown in the figure, a horizontal pulverizer includes a pulverization chamber closed by an end plate 6 and a side plate 9. A feeding port 7 is arranged above the pulverization chamber, and a rotor 8 is arranged in the pulverization chamber, and the rotor 8 is fixed at a level. On the main shaft 1 passing through the two end plates, the main shaft 1 is fixed on the frame 4 through bearings, and there is a discharge port 2 under the crushing chamber, and the crushing chamber and the discharge port 2 are separated by a sieve plate 3 with dense mesh The sieve plate 3 is arranged on the outer side of the rotor 8 in a semi-enclosed structure, and the two ends of the upper side of the main shaft 1 are provided with an air supplement port 5, and the air supplement port is composed of a plurality of strip-shaped through slots 10.

[0013] When working, the external natural wind enters the crushing chamber from the supplementary air port 5 along the axial direction, and spreads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com