Respiration tube disinfecting machine

The technology of breathing tube and disinfection machine is applied in the innovative technology field of breathing tube disinfection machine, which can solve the problems of long drying time, secondary pollution of breathing tube and accessories, and the inability of patients to meet the needs, and achieves simple structure, low price, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

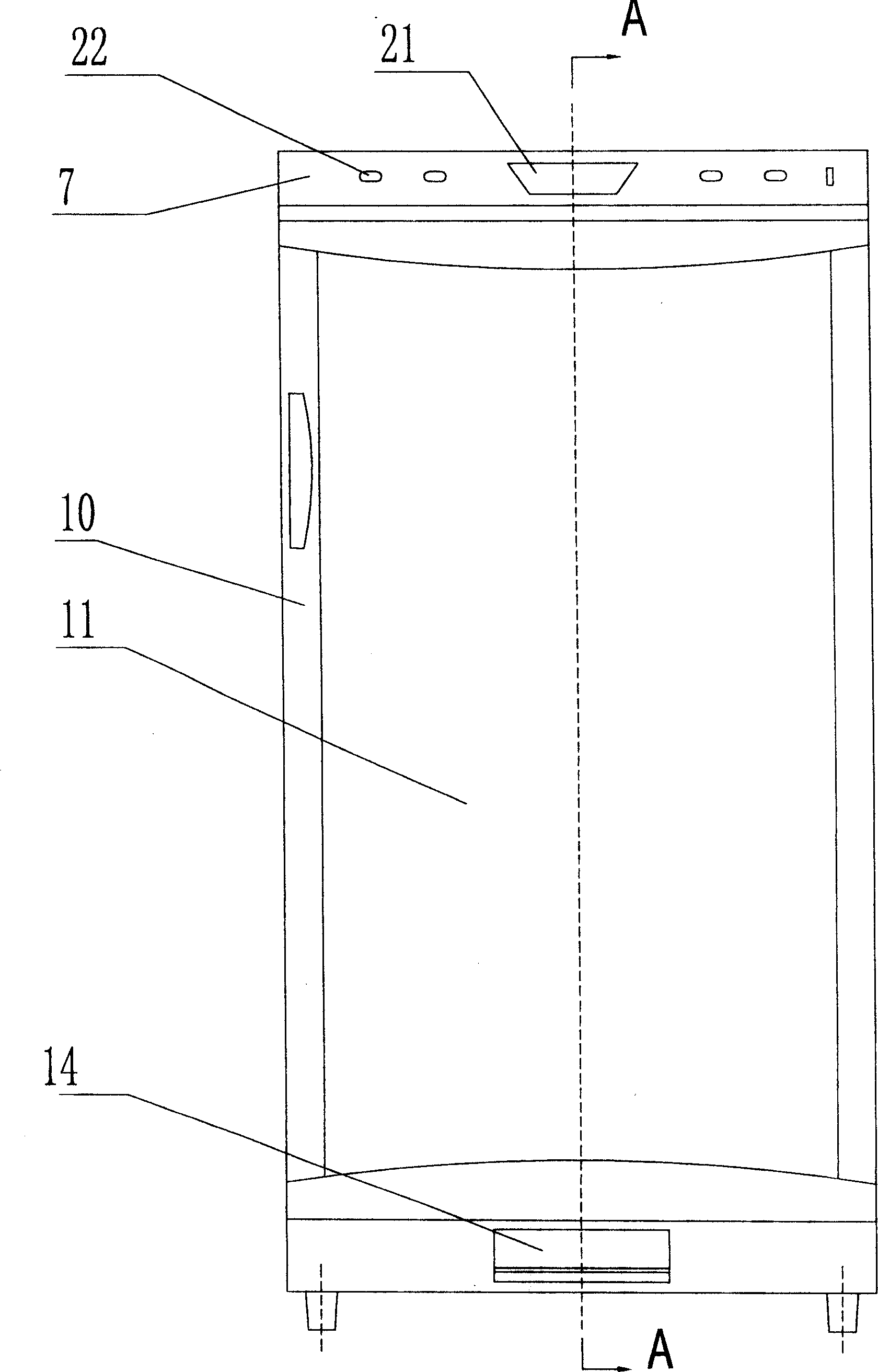

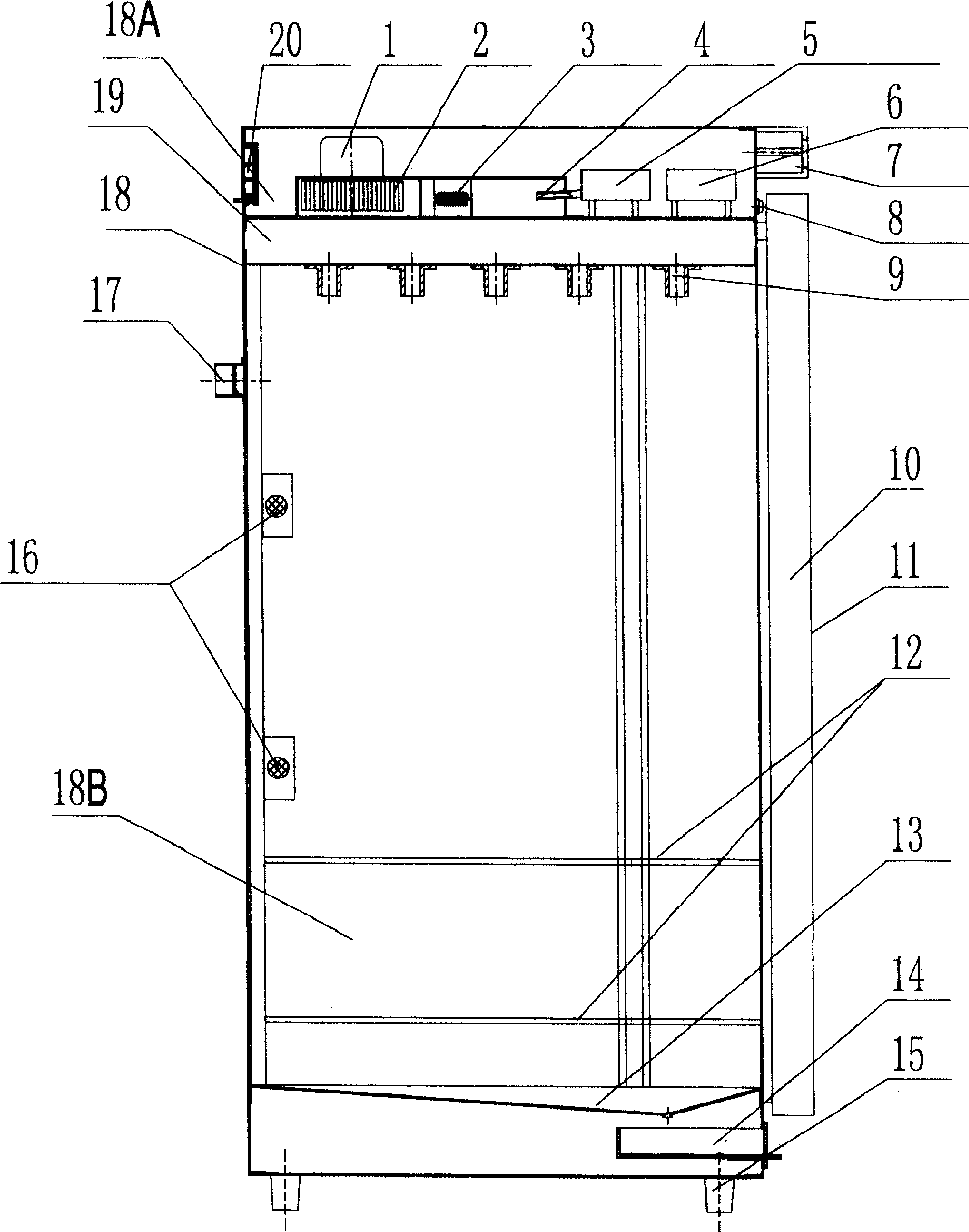

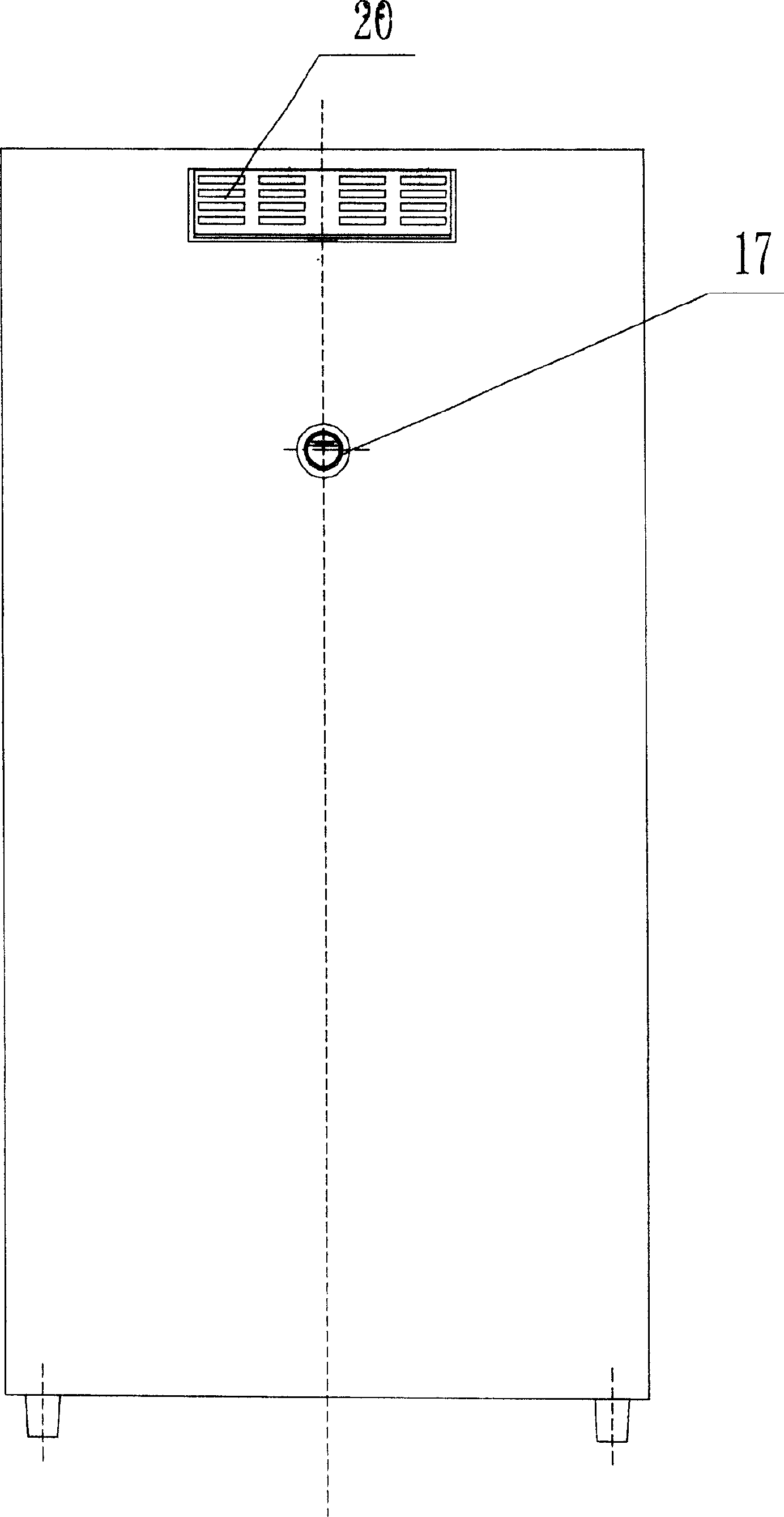

[0020] The structure diagram of the present invention is as figure 1 , 2 , 3, including a hot air device, an ozone generator (5), a casing (18), a door body (10) and a control device thereof, wherein the casing (18) is provided with a cavity body which is divided into upper The supporting plate (19) of chamber (18A) and lower chamber (18B), hot air device includes motor (1), wind wheel (2), heater (3), motor (1), wind wheel (2), heating Device (3), ozone generating device (5) are all installed on the top surface of support plate (19), and the wind wheel (2) driven by motor (1) is placed on the side of heater (3), ozone generation The air inlet (4) of the device (5) is opposite to the hot air device, and the bottom of the support plate (19) is provided with a port (9) that communicates with the upper chamber (18A) and can be nested with a breathing tube. The motor (1), heating The device (3) and the ozone generator (5) are electrically connected with the control device. Thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com