Stepped heating combined oil tank

A step-by-step heating and oil tank technology, which is applied in the direction of fuel heat treatment devices, engine components, liquid fuel feeders, etc., can solve the problems of difficult to use No. 0 diesel oil normally, and achieve the effect of solving the difficulty of starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

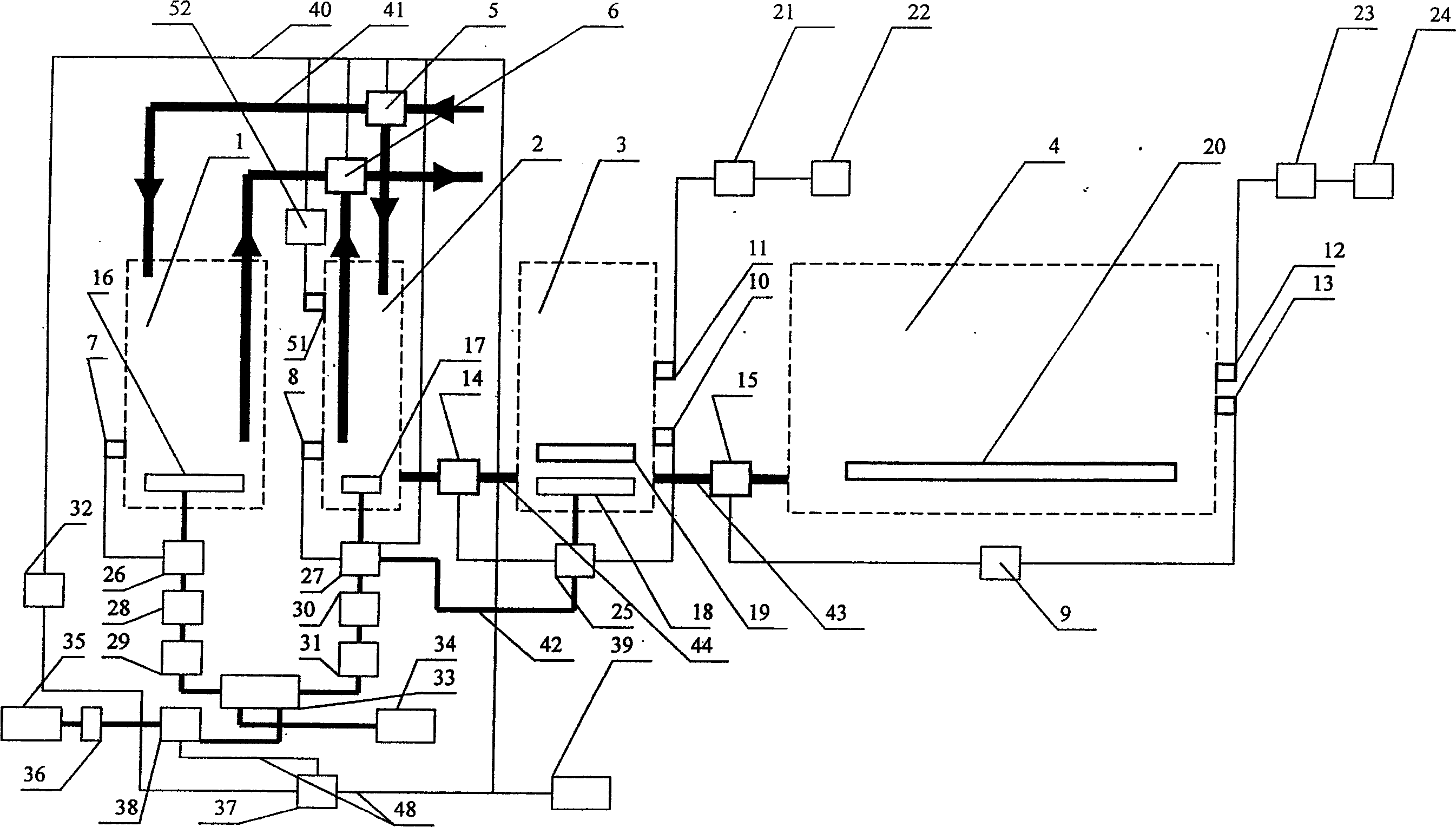

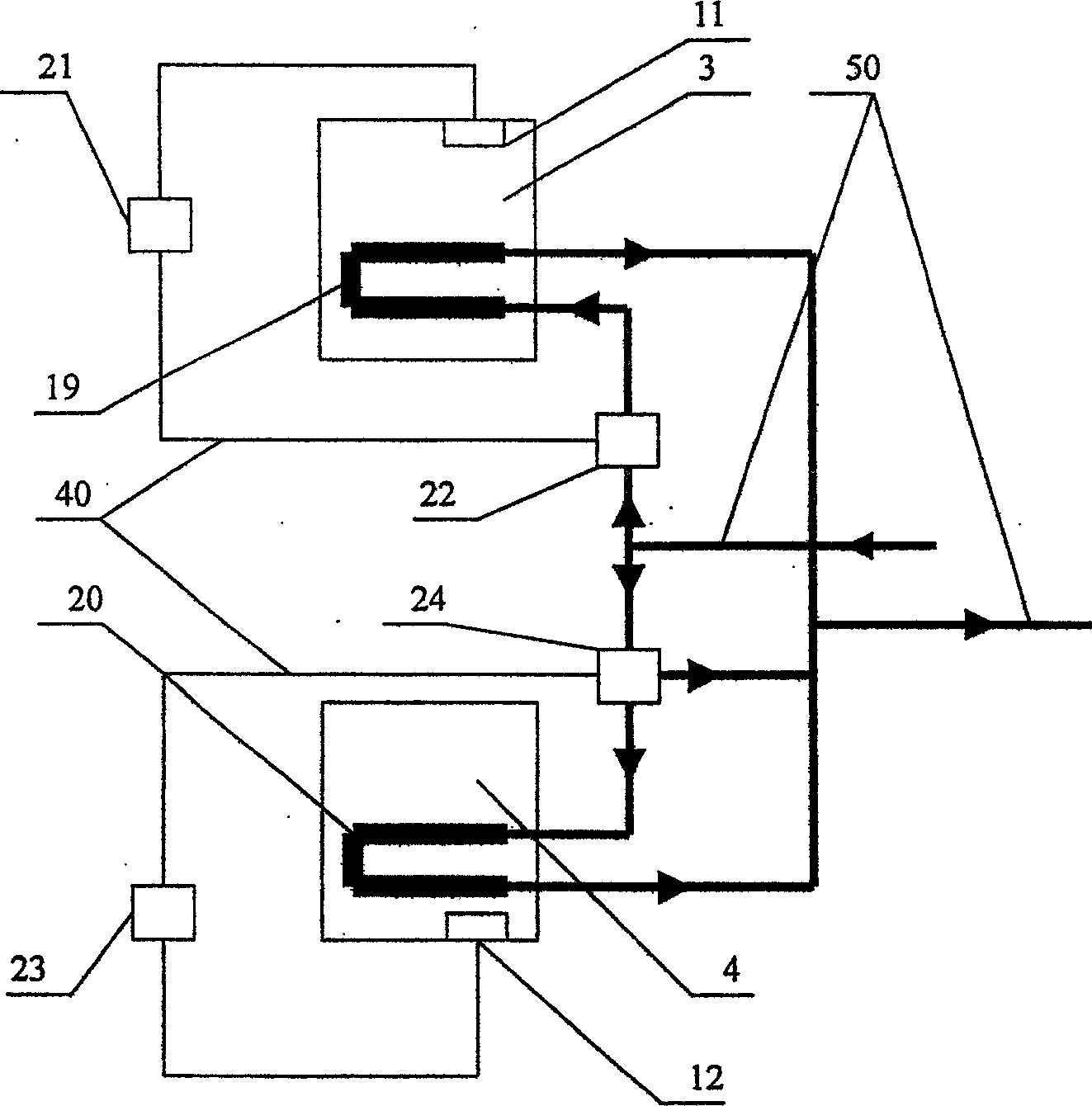

[0014] The working principle and step-by-step heating of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0015] figure 1 One embodiment of the invention is shown. The step-by-step heating compound oil tank in this embodiment is composed of an oil cavity, an electric heater arranged in the oil cavity, and an oil delivery pipeline. In this embodiment, the oil chamber is set as four chambers (see the dotted line box in the figure), wherein chamber 1 is an auxiliary chamber, chamber 2 is a primary chamber, and chamber 3 is a secondary chamber body, cavity 4 is a secondary cavity added in the basic structure. In practical applications, the number of cavities at each level can be set between 1 and 10 according to actual needs. The cavities at all levels are arranged step by step according to the volume of the cavities. For the convenience of system layout, the cavities can be installed in one place as a whole, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com