Structure for supplying hot air in drum type washing machine and operation control method thereof

A technology for drum washing machines and drum washing machines, which is applied to other washing machines, washing machines with containers, household clothes dryers, etc., and can solve the problems of reduced drying performance, reduced drying efficiency, weakened drying performance and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. Wherever possible, the same parts are represented by the same or like reference numerals throughout the drawings.

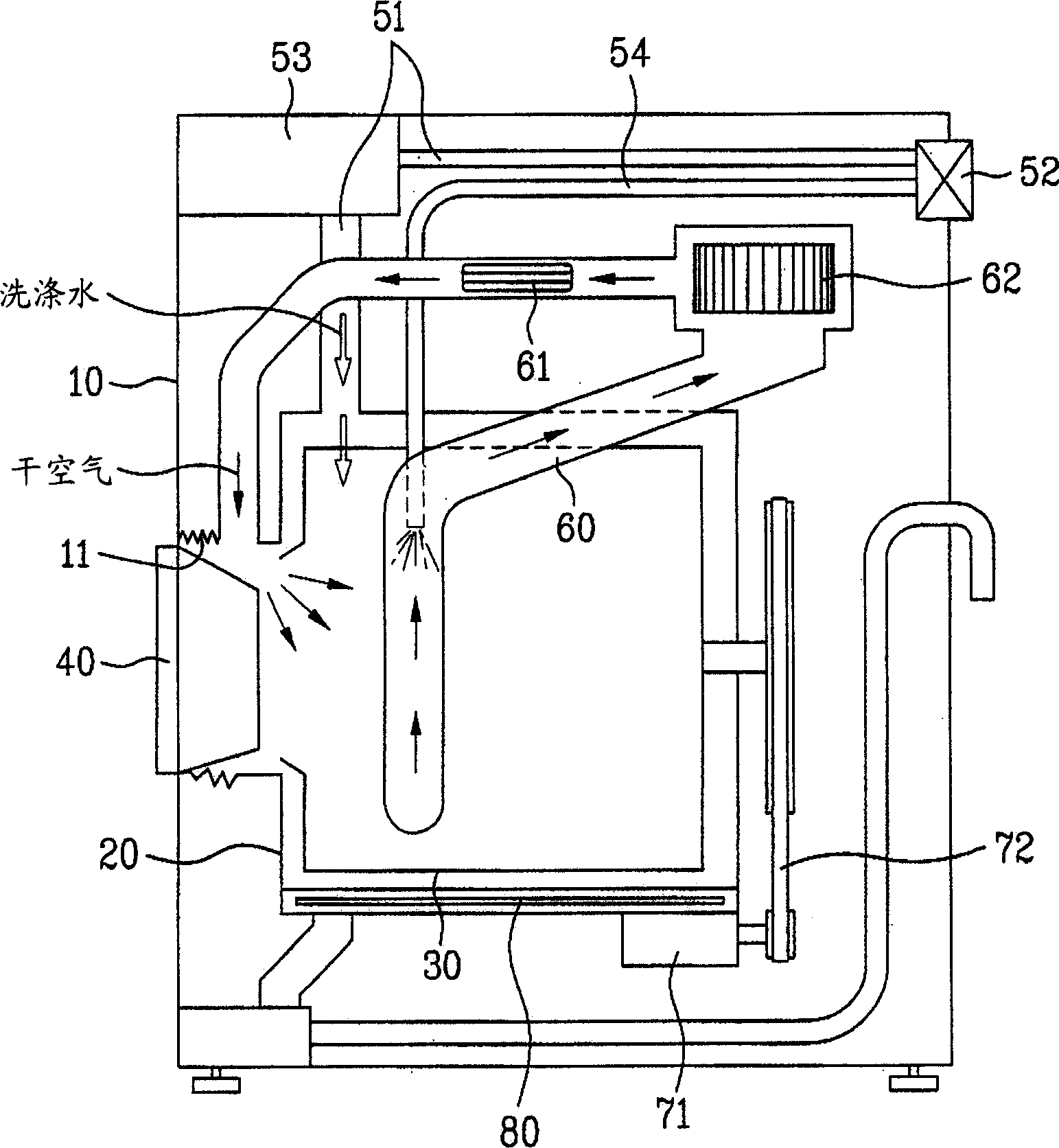

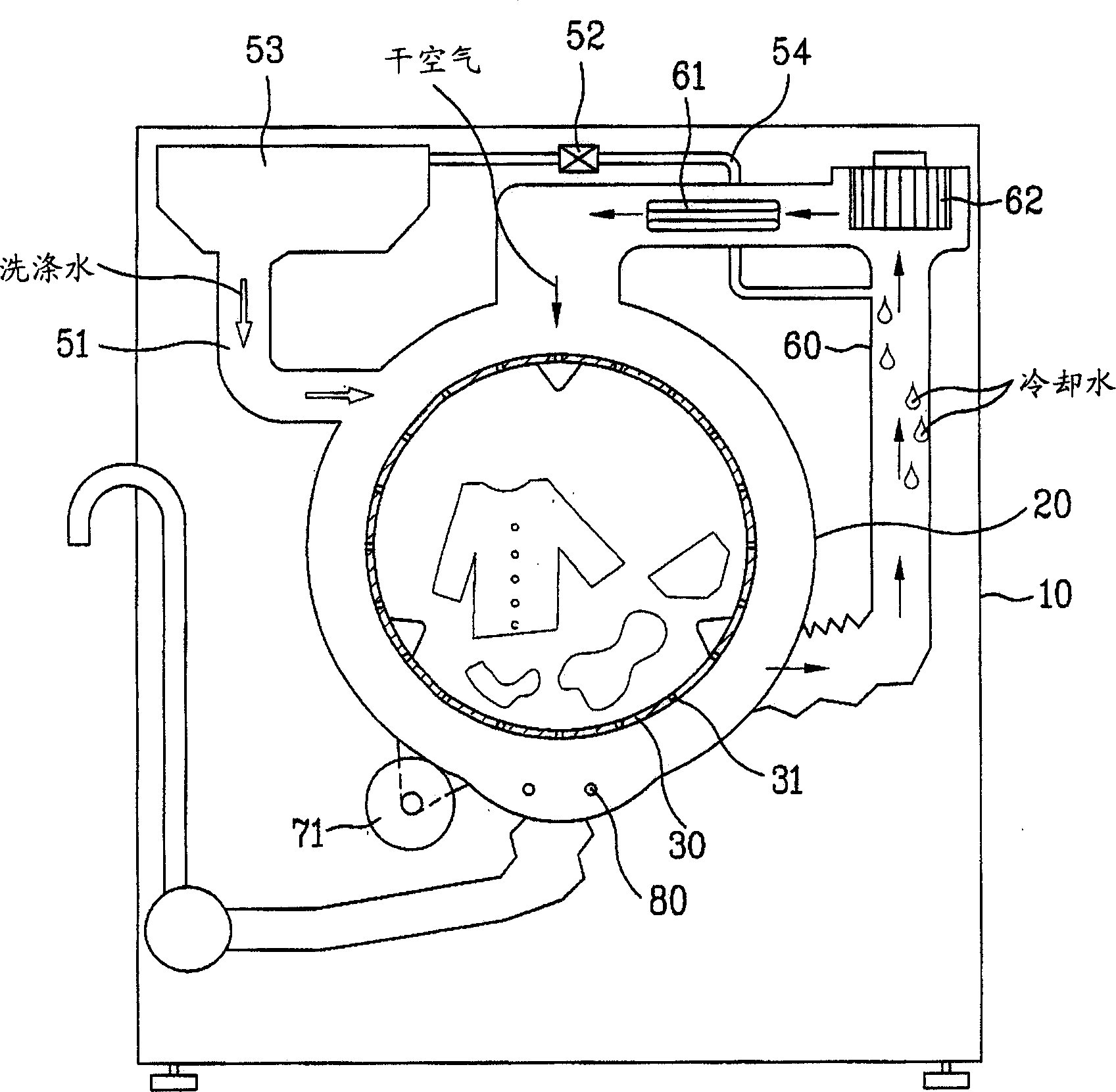

[0046] see Figure 4 with Figure 5 As shown, an embodiment of a structure for supplying hot air in a drum washing machine and an operation control method thereof will be described as follows.

[0047] The structure of the drum washing machine according to the first preferred embodiment of the present invention will be referred to Figure 4 Be explained.

[0048] see Figure 4 , the drum washing machine comprises: a tub 20 for containing washing water; a drum 30 rotatably installed inside the tub 20 for loading clothes; a drying heater 61 for heating the air supplied to the drum 30; pipe 60, the drying pipe forms a flow path so as to supply hot air heated by the drying heater 61; and a fan 62 for forcibly supplying the hot air he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com