Method for switching a hydraulic pressure intensifier

A hydraulic and multiplier technology, which is applied in the direction of fluid pressure actuators, servo motors, servo meter circuits, etc., can solve the problems of dependence, complexity, and difficult adjustment of accurate time points, etc., to achieve weakened mechanical friction, simple structure, and time-saving optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

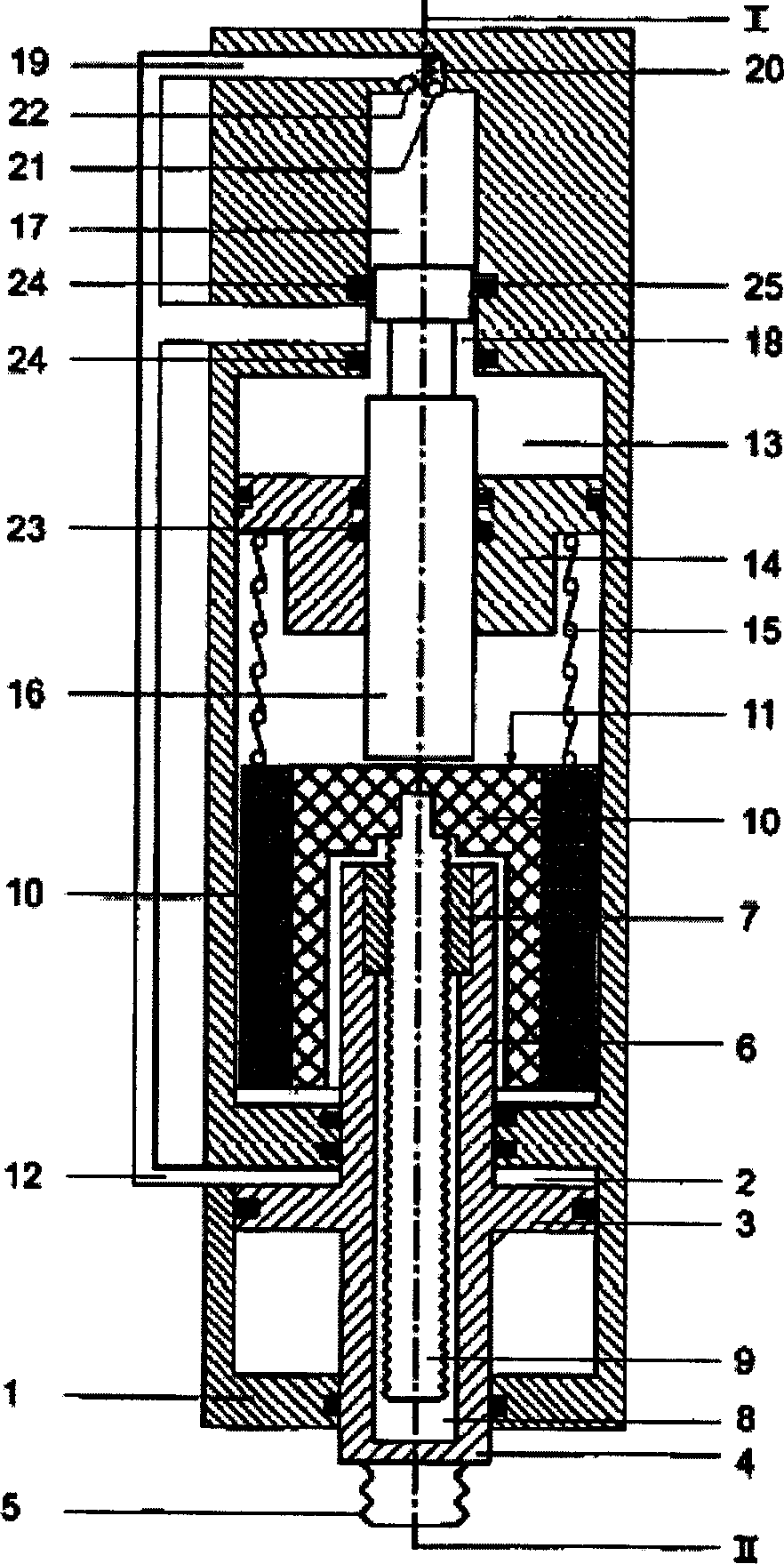

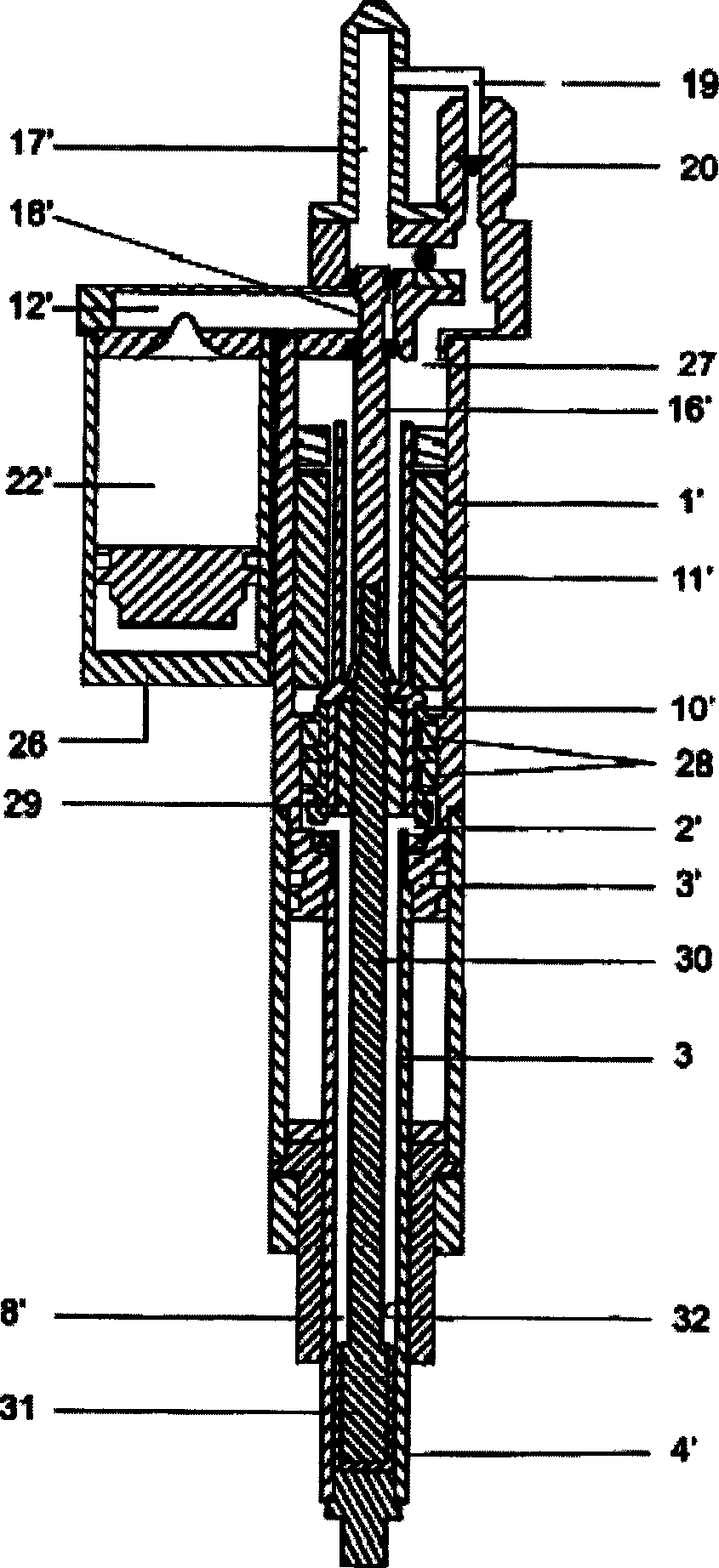

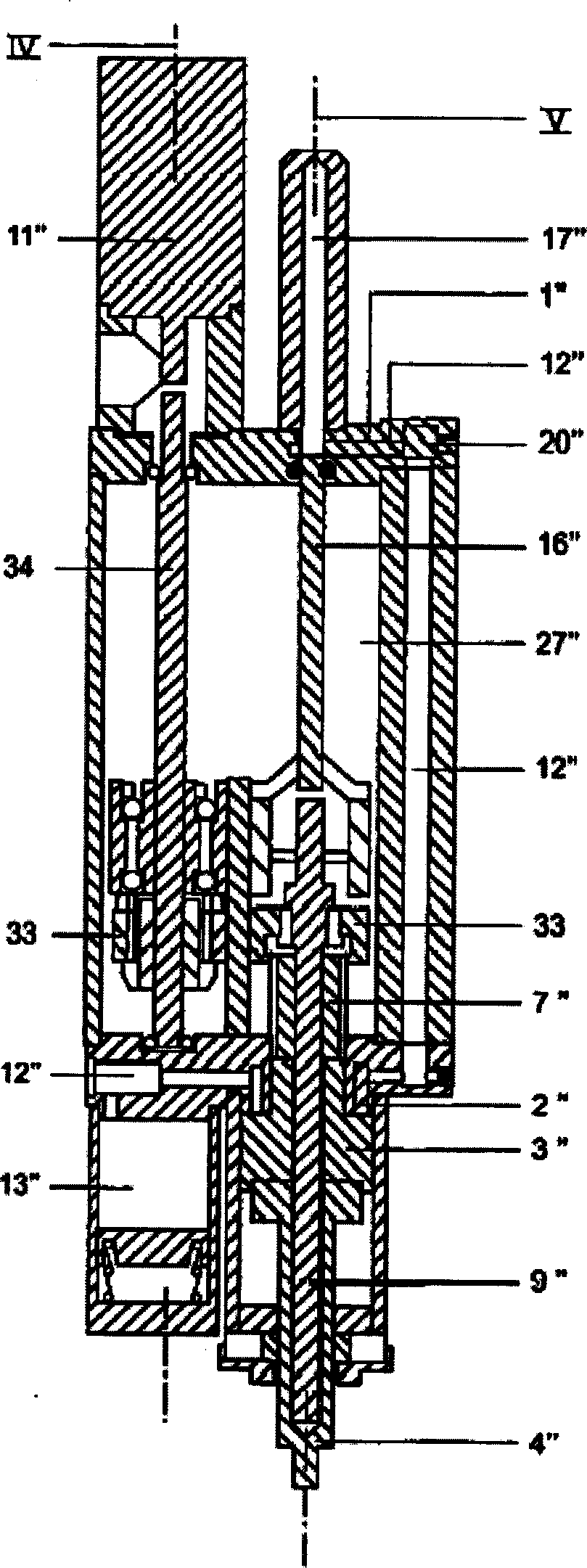

[0025] exist figure 1 The hydraulic pressure multiplier given as a first example in , is a relatively small device in a compact component form. In this case, the axially displaceable part is arranged along the longitudinal axis I. In the housing 1 there is radially sealed a working piston 3 which is axially displaceable in a cylinder-like working chamber 2 . On the working piston 3 a piston rod 4 is mounted, the free end of which has a thread 5 for fastening a tool and protrudes out of the housing 1 for tool control. Working piston 3 is secured against self-rotation by means not shown. In addition, the side of the working piston 3 facing away from the piston rod 4 is equipped with a sleeve-like section 6 , in which a nut 7 is mounted in a rotationally coupled manner, which connects the working piston 3 , the piston rod 4 and the center in the section 6 . The blind hole 8 is closed.

[0026] Inside the nut 7 runs a threaded spindle 9 which in turn is connected in rotation w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com