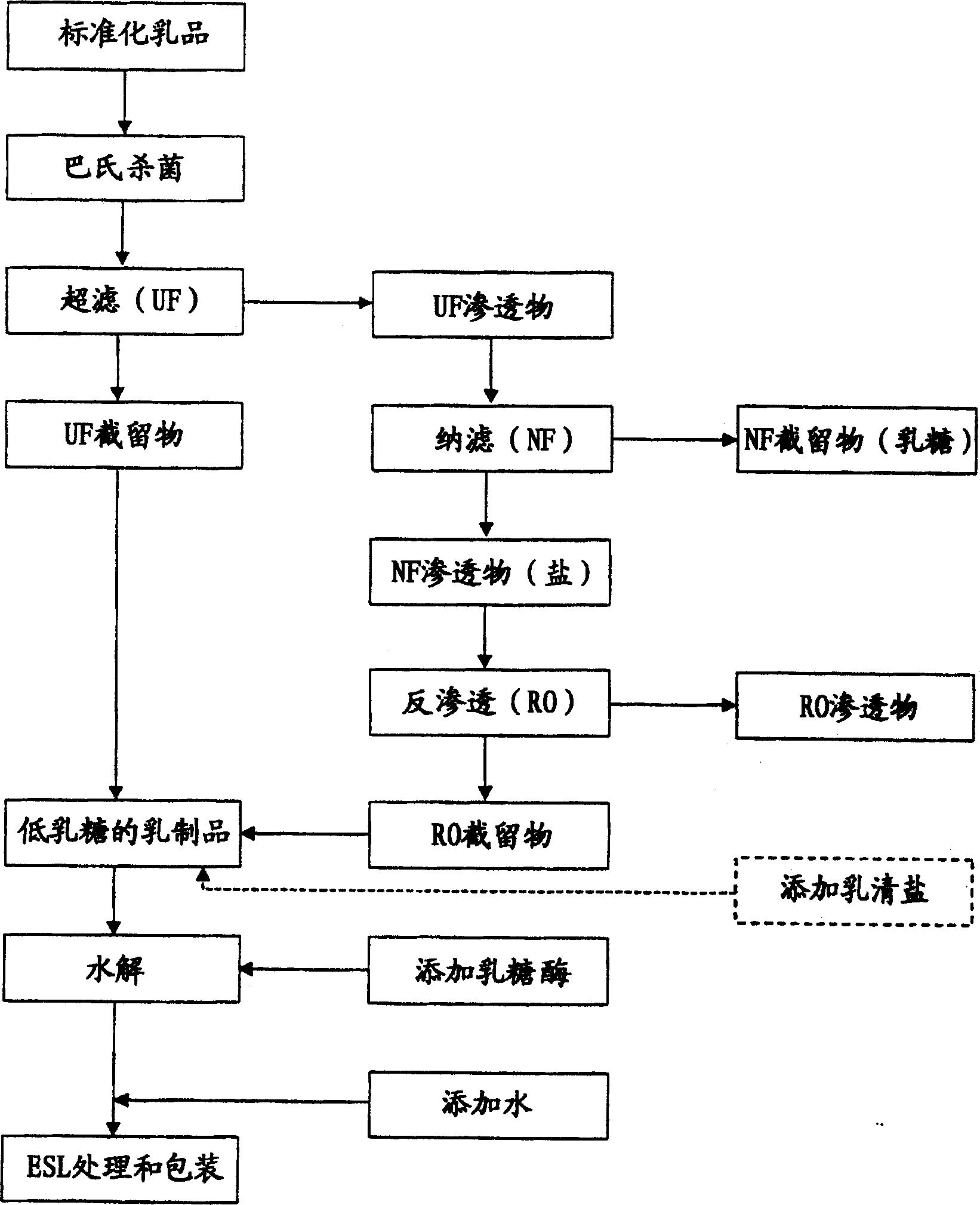

Process for producing a lactose-free milk product

A technology for dairy products and dairy products, applied in dairy products, milk formulations, applications, etc., can solve the problems of high purchase price, time-consuming process of chromatographic separation, and changes in sensory properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 30 liters of pasteurized (72°C, 15 sec) milk with a fat content of 1.5% at 50°C using a GR61PP membrane with a critical value of 20,000 Daltons through a lab-scale Labstak ultrafilter at a concentration ratio of 1.5 Perform ultrafiltration. The resulting retentate (20 L) and permeate (10 L) were recovered.

[0039] The permeate was further subjected to nanofiltration at room temperature through a Millipore Nanomax-50 nanofiltration membrane at a concentration factor of 4 so that monovalent ions passed through the membrane (NaCl retention <65%). Lactose, the major component of the permeate (7.5 L), remained in the retentate fraction upon nanofiltration. In nanofiltration, the salt, the lactose fraction (2.5 L), was separated from the UF permeate, so this nanofiltration retentate was suitable for further use as a low sodium lactose fraction.

[0040] The nanofiltration permeate (7.5 L) was concentrated at room temperature using a reverse osmosis membrane Nanomax-95 (Mil...

Embodiment 2

[0047] Thirty liters of pasteurized (72°C, 15 sec) milk with a fat content of 1.5% was subjected to ultrafiltration at 50°C with a concentration ratio of 1.5 using a GR61PP membrane with a cut-off value of 20,000 Daltons. The resulting retentate (20 L) and permeate (10 L) were recovered.

[0048] In the dairy industry, instead of the RO retentate made from the UF permeate of dairy products, a concentrate made from the permeate of ultrafiltered whey (RO retentate) is used, the composition of which is similar to that obtained from dairy UF permeate. The RO retentate produced by UF permeate was similar (Tables 1 and 2).

[0049] 69.2g UF retentate was mixed with 10.5g salt concentrate and 20.3g water and 0.35g HA lactase (Chr. Hansen A / S, Denmark) was added. The mixture was hydrolyzed at 10°C for 24 hours, during which time the lactose content was reduced to less than 0.01%. Table 2 shows the composition of UF retentate and RO retentate. The resulting product is very close in ...

Embodiment 3

[0054] The dairy products obtained in Examples 1 and 2 can also be dried into powder. The milk was pasteurized at 75°C±3°C / 3min and evaporated to 40-45% dry matter content. It is then fed into a spray dryer. Drying was carried out with a plate dryer (laminar dryer, Filtermat) at drying values corresponding to normal lactose-hydrolyzed milk powder.

[0055] Nozzle pressure 110-150 bar

[0056] Nozzle air temperature 185~190℃

[0057] Plate air temperature 160~170℃

[0058] After drying 120~130℃

[0059] Cooling 20~25℃

[0060] Outlet temperature 60~65℃

[0061] Target Moisture 1.75%, Max 2.3%

[0062] The powder preparation described is particularly suitable for the preparation of lactose-free non-fat milk powders, but fat-containing milk powders can also be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com