Composition for heat conductive siloxanes heat release and its using method

A technology of thermal conductivity and composition, which is applied in chemical instruments and methods, semiconductor devices, and other chemical processes, can solve the problems of high stress of exothermic electronic parts, damage and difficulties of exothermic electronic parts, and achieve good discharge The effect of thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

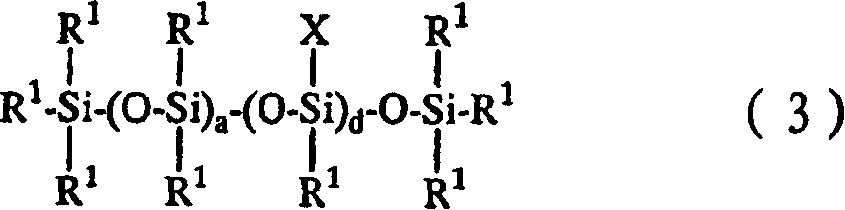

Method used

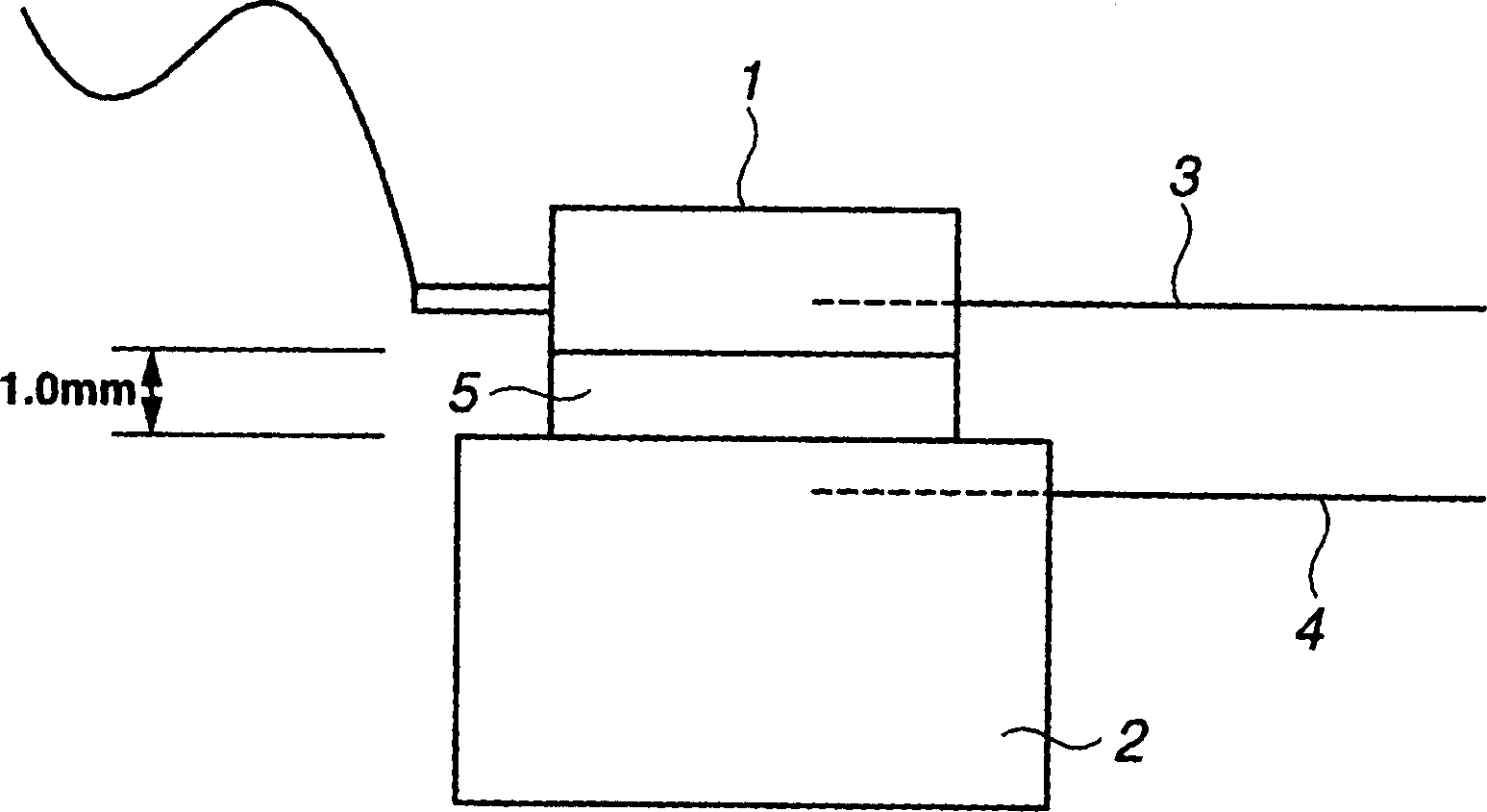

Image

Examples

Embodiment 1

[0055] will have 10000mm 2 Viscosity per s, 100 g of dimethyl polysiloxane (Vi group content: 0.00525 mol / 100 g) with vinyl groups at both ends, and 500 g of alumina with an average particle diameter of 1 μm are charged into a Shinagawa-style universal mixer, and mixed for 60 Minutes later, 0.2 g of a 2-ethylhexanol solution of chloroplatinic acid (2.0% by mass of platinum element), 4.0 g of a toluene solution of ethynylcyclohexanol (50% by mass) as a reaction control agent, and the following 5.0 g of organohydrogenpolysiloxane (Si-H group amount: 0.00184 mol / g) represented by formula (7), mixed for 10 minutes for each additive, and finally mixed for 10 minutes under a reduced pressure of -700mmHg, Composition a is obtained.

[0056]

Embodiment 2

[0062] will have 10000mm 2 Viscosity per s, 100 g of dimethyl polysiloxane (Vi group content: 0.00525 mol / 100 g) with vinyl groups at both ends, and 500 g of alumina with an average particle diameter of 1 μm are charged into a Shinagawa-style universal mixer, and mixed for 60 Minutes later, 0.2 g of a 2-ethyl-hexanol solution of chloroplatinic acid (the amount of platinum element is 2.0% by mass), 4.0 g of 3-methyl-1-butyn-3-ol as a reaction control agent, and the above 5.0 g of the organohydrogenpolysiloxane represented by the formula (7) was mixed for 10 minutes with respect to each additive, and finally mixed for 10 minutes under a reduced pressure condition of -700 mmHg to obtain a composition d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com